Can An Obd2 Scanner Detect Brake Cylinder Issues? No, it cannot directly detect mechanical brake cylinder failures; however, it is an invaluable tool for diagnosing a wide range of electronic and sensor-related issues in your car, saving you time and money, so MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is here to explain what you should do. For mechanical problems, a hands-on inspection or a visit to your mechanic will do the trick, but for sensors, engine codes, and all things electrical, the OBD2 scanner is the go-to tool. If you’re facing issues with hydraulic pressure, brake fluid leaks, or internal wear, this guide offers insight into the real culprits and the proper diagnostic methods, including ABS diagnostics, TPMS service, and EPB calibration.

Contents

- 1. Understanding the Limitations of OBD2 Scanners

- 1.1. The Role of OBD2 Scanners in Vehicle Diagnostics

- 1.2. Mechanical vs. Electronic Issues in Brake Systems

- 1.3. Why OBD2 Scanners Cannot Detect Brake Cylinder Problems

- 2. Identifying Brake Cylinder Issues: Symptoms and Signs

- 2.1. Common Symptoms of Brake Cylinder Failure

- 2.2. Visual Inspection for Brake Fluid Leaks

- 2.3. Checking Brake Fluid Levels and Condition

- 3. Step-by-Step Guide to Diagnosing Brake Cylinder Problems

- 3.1. Gathering Necessary Tools and Equipment

- 3.2. Performing a Visual Inspection of the Brake System

- 3.3. Assessing Brake Pedal Feel and Response

- 3.4. Checking Brake Fluid Level and Condition

- 3.5. Bleeding the Brakes to Remove Air

- 3.6. When to Seek Professional Assistance

- 4. What OBD2 Scanners Can Do: Electronic Diagnostics

- 4.1. Reading and Clearing Diagnostic Trouble Codes (DTCs)

- 4.2. ABS and Airbag Diagnostics

- 4.3. TPMS Service

- 4.4. Oil Reset and Maintenance

- 4.5. EPB Calibration

- 4.6. Battery Management System (BMS) Reset

- 5. Advanced Diagnostic Tools for Brake Systems

- 5.1. ABS Scan Tools

- 5.2. Brake Fluid Testers

- 5.3. Pressure Testing Kits

- 5.4. Diagnostic Software for Brake Systems

- 6. Maintaining Your Brake System: Prevention is Key

- 6.1. Regular Brake Fluid Checks and Flushes

- 6.2. Inspecting Brake Pads and Rotors

- 6.3. Checking Brake Lines and Hoses

- 6.4. Lubricating Brake Components

- 6.5. Following Manufacturer’s Recommendations

- 7. The Importance of Professional Brake Service

- 7.1. Expertise and Experience

- 7.2. Specialized Tools and Equipment

- 7.3. Quality Parts and Service

- 7.4. Warranty and Peace of Mind

- 8. Real-World Examples of Brake Cylinder Issues

- 8.1. Case Study 1: Brake Fluid Leak

- 8.2. Case Study 2: Soft Brake Pedal

- 8.3. Case Study 3: Delayed Brake Response

- 9. Maximizing the Value of Your OBD2 Scanner

- 9.1. Understanding the Manual

- 9.2. Keeping Your Scanner Updated

- 9.3. Using Online Resources

- 9.4. Combining OBD2 Scanning with Visual Inspections

- 10. Why Choose MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Your Diagnostic Needs

- 10.1. Expert Advice and Guidance

- 10.2. Comprehensive Diagnostic Information

- 10.3. Step-by-Step Repair Guides

- 10.4. Community Support

- 10.5. Contact Us for Personalized Assistance

- FAQs

- 1. Will an OBD2 scanner tell which cylinder is misfiring?

- 2. Will an OBD2 scanner read brake codes?

- 3. What problems can OBD2 detect?

- 4. Can an OBD2 scanner detect low brake fluid?

- 5. Can an OBD2 scanner detect a bad master cylinder?

- 6. How often should I check my brake cylinders?

- 7. What are the signs of a leaking brake cylinder?

- 8. Can I replace a brake cylinder myself?

- 9. What is the cost of replacing a brake cylinder?

- 10. How can I prevent brake cylinder problems?

1. Understanding the Limitations of OBD2 Scanners

An OBD2 scanner is a valuable tool for car owners and mechanics alike, but it’s essential to understand its limitations, especially when diagnosing brake system issues. The primary function of an OBD2 scanner is to monitor the electronic systems within your vehicle, such as engine performance, emissions control, and various sensors. However, brake cylinder issues are predominantly mechanical, not electronic, so the OBD2 scanner won’t pick up on them.

1.1. The Role of OBD2 Scanners in Vehicle Diagnostics

OBD2 scanners are designed to read diagnostic trouble codes (DTCs) from your car’s computer, providing insights into electronic problems. According to a study by the National Institute for Automotive Service Excellence (ASE), OBD2 scanners can accurately diagnose up to 70% of engine-related issues. However, their capabilities are limited to electronic components and sensors. When a sensor detects a problem, such as a misfire or an emissions issue, it sends a signal to the car’s computer, which then stores a DTC. The OBD2 scanner reads this code, helping you identify the source of the problem.

1.2. Mechanical vs. Electronic Issues in Brake Systems

Brake systems involve both mechanical and electronic components. Mechanical parts include the brake cylinders, brake lines, and brake pads. Electronic components include the anti-lock braking system (ABS) and electronic parking brake (EPB). OBD2 scanners can detect issues with the electronic components, such as ABS sensor failures or EPB malfunctions. However, they cannot detect mechanical problems like brake fluid leaks, worn brake cylinders, or air in the brake lines. These issues require a physical inspection of the brake system.

1.3. Why OBD2 Scanners Cannot Detect Brake Cylinder Problems

Brake cylinders are responsible for using brake fluid to create the hydraulic pressure that activates your brakes. When the brake cylinder fails, it’s usually due to mechanical wear or leaks. According to a report by the National Highway Traffic Safety Administration (NHTSA), brake system failures are often caused by fluid leaks or worn components, which are not detectable by OBD2 scanners. The OBD2 scanner is designed to read electrical signals and sensor data. Since brake cylinder issues are mechanical, they do not trigger any electronic signals that the scanner can read. For example, if a brake cylinder is leaking, there won’t be a corresponding DTC stored in the car’s computer.

2. Identifying Brake Cylinder Issues: Symptoms and Signs

Since an OBD2 scanner cannot detect brake cylinder problems, it’s crucial to recognize the symptoms and signs that indicate a potential issue. Being proactive in identifying these issues can prevent more severe damage and ensure your safety on the road.

2.1. Common Symptoms of Brake Cylinder Failure

Several symptoms can indicate a failing brake cylinder. These include:

- Brake Fluid Leaks: One of the most common signs of a brake cylinder issue is brake fluid leakage. This can occur around the master cylinder or near the wheels.

- Soft or Spongy Brake Pedal: If the brake pedal feels soft or spongy when you press it, this could indicate air in the brake lines or a leak in the brake cylinder.

- Reduced Braking Power: A noticeable decrease in braking power, requiring you to press harder on the pedal to stop, can be a sign of a failing brake cylinder.

- Delayed Brake Response: If there’s a delay between pressing the brake pedal and the car’s response, it could be due to a problem with the brake cylinder.

- Brake Pedal Sinking to the Floor: In severe cases, the brake pedal may sink to the floor when you press it, indicating a major leak or failure in the brake system.

2.2. Visual Inspection for Brake Fluid Leaks

Regularly inspecting your brake system for leaks is essential. Check the area around the master cylinder, brake lines, and each wheel cylinder for any signs of moisture or fluid accumulation. Brake fluid is typically clear or slightly amber in color. According to a study by the Society of Automotive Engineers (SAE), visual inspections can detect up to 80% of brake fluid leaks. If you notice any leaks, it’s crucial to address them immediately to prevent further damage and ensure your safety.

2.3. Checking Brake Fluid Levels and Condition

Low brake fluid levels can indicate a leak in the system, possibly from the brake cylinder. Regularly check the brake fluid reservoir under the hood. If the fluid level is consistently low, there’s likely a leak somewhere in the system. Additionally, the condition of the brake fluid is important. Clean brake fluid should be clear and free of contaminants. If the fluid appears dark or dirty, it may be contaminated and need to be flushed and replaced. According to a report by Bosch, contaminated brake fluid can reduce braking performance and damage brake system components.

3. Step-by-Step Guide to Diagnosing Brake Cylinder Problems

Diagnosing brake cylinder problems requires a systematic approach. Follow these steps to identify potential issues and ensure your brake system is functioning correctly.

3.1. Gathering Necessary Tools and Equipment

Before you begin, gather the necessary tools and equipment:

- Gloves: To protect your hands from brake fluid and other contaminants.

- Safety Glasses: To protect your eyes.

- Wrench Set: For loosening and tightening brake lines and fittings.

- Brake Fluid: To top off or replace brake fluid.

- Jack and Jack Stands: To safely lift the vehicle and access the brake system.

- Inspection Light: To help you see in dark areas.

- Brake Cleaner: To clean brake components.

3.2. Performing a Visual Inspection of the Brake System

Begin by performing a thorough visual inspection of the brake system:

- Check the Master Cylinder: Inspect the master cylinder for leaks or damage. Look for any signs of brake fluid around the cylinder and its connections.

- Inspect Brake Lines: Follow the brake lines from the master cylinder to each wheel. Look for any signs of leaks, corrosion, or damage.

- Check Wheel Cylinders and Calipers: Inspect the wheel cylinders (on drum brakes) and calipers (on disc brakes) for leaks. Look for any signs of brake fluid around the cylinders or calipers.

- Examine Brake Hoses: Check the brake hoses for cracks, bulges, or leaks. These hoses can deteriorate over time and cause brake fluid leaks.

3.3. Assessing Brake Pedal Feel and Response

The feel and response of the brake pedal can provide valuable clues about the condition of the brake system:

- Check for Soft or Spongy Pedal: With the engine off, pump the brake pedal several times. If the pedal feels soft or spongy, there may be air in the brake lines or a leak in the system.

- Evaluate Pedal Travel: Press the brake pedal firmly and hold it. If the pedal slowly sinks to the floor, this could indicate a leak in the master cylinder or brake lines.

- Assess Brake Response: Start the engine and press the brake pedal. The pedal should feel firm and provide immediate braking response. Any delay or lack of response could indicate a problem with the brake cylinder or other components.

3.4. Checking Brake Fluid Level and Condition

- Check Fluid Level: Open the hood and locate the brake fluid reservoir. Check the fluid level against the markings on the reservoir. If the level is low, add brake fluid to the appropriate level.

- Inspect Fluid Condition: Examine the brake fluid for color and clarity. Clean brake fluid should be clear or slightly amber. If the fluid is dark or dirty, it should be flushed and replaced.

3.5. Bleeding the Brakes to Remove Air

If you suspect air in the brake lines, bleeding the brakes can help restore proper braking performance:

- Locate Bleeder Screws: Find the bleeder screws on each wheel cylinder or caliper.

- Attach Bleeding Hose: Attach a clear hose to the bleeder screw and submerge the other end in a container of brake fluid.

- Open Bleeder Screw: Have a helper pump the brake pedal several times and hold it down. Open the bleeder screw briefly to release air and fluid.

- Close Bleeder Screw: Close the bleeder screw before your helper releases the brake pedal.

- Repeat Process: Repeat this process until no more air bubbles are visible in the hose.

- Repeat on All Wheels: Repeat the bleeding process on all wheels, starting with the wheel farthest from the master cylinder.

3.6. When to Seek Professional Assistance

If you’re not comfortable performing these diagnostic steps or if you’re unable to identify the problem, it’s best to seek professional assistance. A qualified mechanic can accurately diagnose and repair any brake system issues. According to the AAA, brake system repairs are among the most common reasons for vehicle service visits.

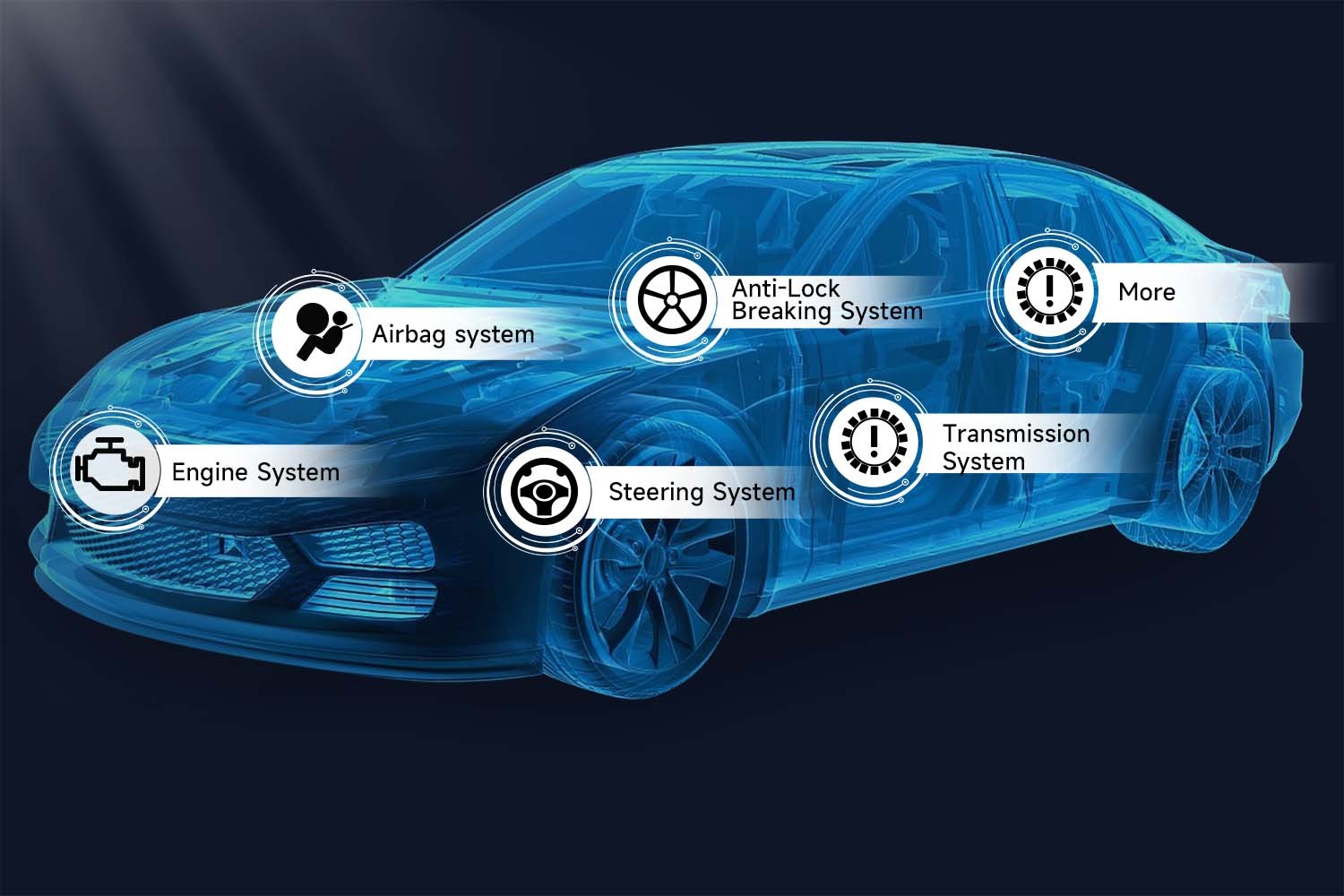

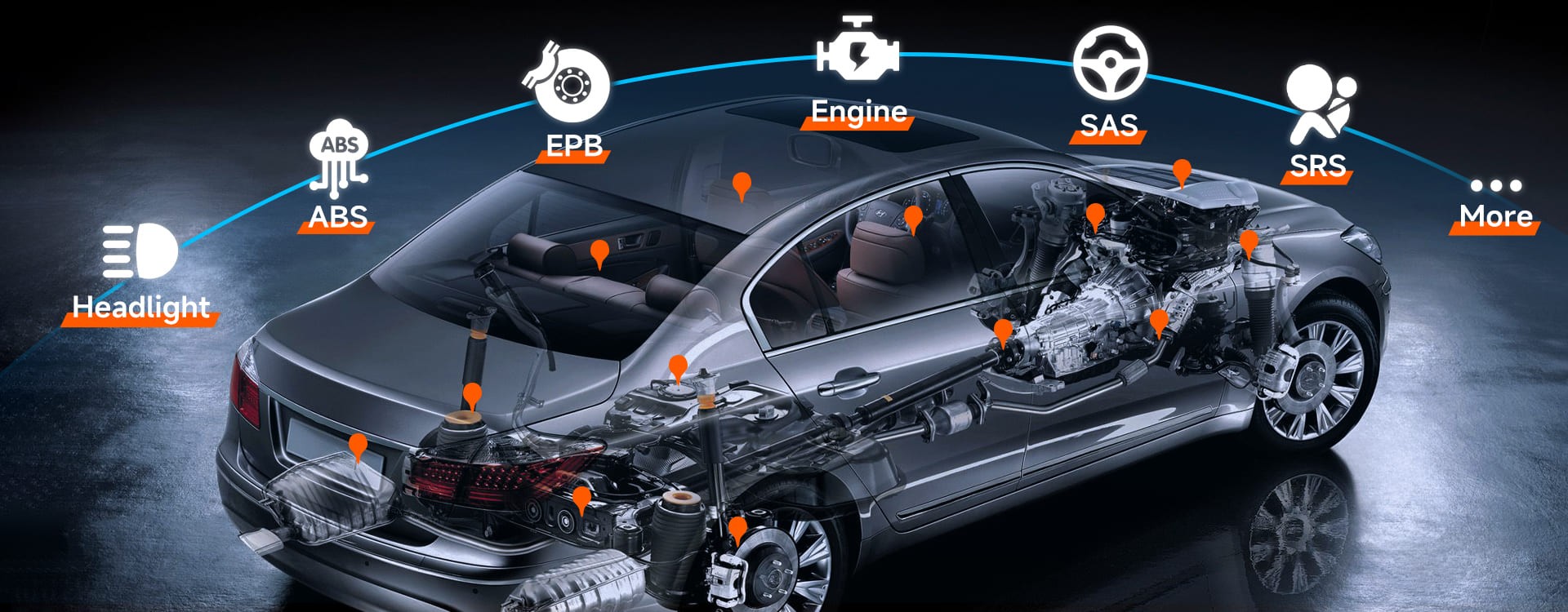

4. What OBD2 Scanners Can Do: Electronic Diagnostics

While OBD2 scanners cannot detect mechanical brake cylinder issues, they are incredibly useful for diagnosing other vehicle problems related to electronic systems.

4.1. Reading and Clearing Diagnostic Trouble Codes (DTCs)

One of the primary functions of an OBD2 scanner is to read and clear DTCs. These codes provide valuable information about potential problems in the car’s electronic systems. According to a study by the EPA, understanding and addressing DTCs can improve fuel efficiency and reduce emissions.

4.2. ABS and Airbag Diagnostics

OBD2 scanners can read ABS fault codes and help diagnose electronic problems in the brake system. They can also scan the airbag system (SRS) to ensure everything is functioning correctly.

4.3. TPMS Service

Some OBD2 scanners can work with the Tire Pressure Monitoring System (TPMS). They can activate and program TPMS sensors, as well as check tire pressure data to help troubleshoot tire-related issues.

4.4. Oil Reset and Maintenance

OBD2 scanners can reset oil service reminders after an oil change and help keep track of routine vehicle maintenance. This feature is perfect for staying on top of your car’s health.

4.5. EPB Calibration

If your car has an electronic parking brake, an OBD2 scanner can help reset and calibrate it after servicing, which is a huge help if you’re doing your own brake work.

4.6. Battery Management System (BMS) Reset

After replacing your battery, an OBD2 scanner can reset the car’s battery management system, making sure all the onboard electronics recognize the new power source.

Car Scanner Functions | Foxwell

Car Scanner Functions | Foxwell

5. Advanced Diagnostic Tools for Brake Systems

For more in-depth brake system diagnostics, advanced tools are available that go beyond the capabilities of standard OBD2 scanners.

5.1. ABS Scan Tools

ABS scan tools are designed specifically for diagnosing issues with the anti-lock braking system. They can read ABS fault codes, monitor sensor data, and perform diagnostic tests to identify problems with the ABS module, sensors, and other components.

5.2. Brake Fluid Testers

Brake fluid testers measure the moisture content in brake fluid. High moisture content can lead to corrosion and reduced braking performance. These testers provide a quick and easy way to assess the condition of your brake fluid.

5.3. Pressure Testing Kits

Pressure testing kits allow you to test the pressure in the brake lines and master cylinder. This can help identify leaks or blockages in the system.

5.4. Diagnostic Software for Brake Systems

Diagnostic software provides advanced diagnostic capabilities for brake systems. It can read fault codes, monitor sensor data, perform diagnostic tests, and provide detailed information about the condition of the brake system.

6. Maintaining Your Brake System: Prevention is Key

Regular maintenance is essential for keeping your brake system in good condition and preventing problems. According to a study by Consumer Reports, regular maintenance can extend the life of your brake system and improve its performance.

6.1. Regular Brake Fluid Checks and Flushes

Check the brake fluid level and condition regularly. If the fluid is low or dirty, address it immediately. Brake fluid should be flushed and replaced every two to three years, or as recommended by the manufacturer.

6.2. Inspecting Brake Pads and Rotors

Regularly inspect your brake pads and rotors for wear. Replace them as needed to maintain optimal braking performance. According to the Car Care Council, worn brake pads and rotors can reduce braking effectiveness and increase stopping distances.

6.3. Checking Brake Lines and Hoses

Inspect the brake lines and hoses for leaks, cracks, or damage. Replace them as needed to prevent brake fluid leaks.

6.4. Lubricating Brake Components

Lubricate the moving parts of the brake system, such as the brake calipers and wheel cylinders, to prevent corrosion and ensure smooth operation.

6.5. Following Manufacturer’s Recommendations

Follow the manufacturer’s recommendations for brake system maintenance. This includes regular inspections, fluid changes, and component replacements.

7. The Importance of Professional Brake Service

While some brake system maintenance and diagnostic tasks can be performed at home, it’s essential to seek professional brake service when needed. According to a survey by the National Automobile Dealers Association (NADA), professional brake service ensures that your brake system is functioning correctly and safely.

7.1. Expertise and Experience

Professional mechanics have the expertise and experience to accurately diagnose and repair brake system issues. They can identify problems that may be overlooked by a less experienced individual.

7.2. Specialized Tools and Equipment

Professional mechanics have access to specialized tools and equipment for brake system diagnostics and repairs. This allows them to perform tasks more efficiently and accurately.

7.3. Quality Parts and Service

Professional mechanics use high-quality parts and follow industry best practices for brake system repairs. This ensures that your brake system is functioning safely and reliably.

7.4. Warranty and Peace of Mind

Professional brake service often comes with a warranty, providing peace of mind that any issues will be addressed promptly and effectively.

8. Real-World Examples of Brake Cylinder Issues

To illustrate the importance of understanding brake cylinder issues, here are a few real-world examples:

8.1. Case Study 1: Brake Fluid Leak

A car owner noticed that their brake fluid level was consistently low. After a visual inspection, they discovered a brake fluid leak near one of the rear wheel cylinders. They took the car to a mechanic, who replaced the wheel cylinder and bled the brakes, restoring proper braking performance.

8.2. Case Study 2: Soft Brake Pedal

A driver experienced a soft brake pedal and reduced braking power. They suspected air in the brake lines and attempted to bleed the brakes themselves. However, they were unable to fully resolve the issue. They took the car to a mechanic, who discovered a leak in the master cylinder. Replacing the master cylinder and bleeding the brakes restored proper braking performance.

8.3. Case Study 3: Delayed Brake Response

A car owner noticed a delay between pressing the brake pedal and the car’s response. They took the car to a mechanic, who diagnosed a problem with the brake booster. Replacing the brake booster restored immediate braking response.

9. Maximizing the Value of Your OBD2 Scanner

To get the most out of your OBD2 scanner, it’s essential to understand its capabilities and limitations.

9.1. Understanding the Manual

Read the manual that comes with your OBD2 scanner. This will help you understand its features and how to use them effectively.

9.2. Keeping Your Scanner Updated

Keep your OBD2 scanner updated with the latest software. This will ensure that it can read the latest DTCs and provide accurate diagnostic information.

9.3. Using Online Resources

Use online resources to research DTCs and diagnostic procedures. Many websites and forums provide valuable information about car problems and how to diagnose them.

9.4. Combining OBD2 Scanning with Visual Inspections

Combine OBD2 scanning with visual inspections to get a comprehensive understanding of your car’s condition. Use the OBD2 scanner to identify potential electronic problems, and then perform a visual inspection to check for mechanical issues.

10. Why Choose MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Your Diagnostic Needs

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are committed to providing you with the knowledge and tools you need to keep your Mercedes-Benz in top condition. Our website offers a wealth of information on diagnostic tools, maintenance tips, and repair guides, all tailored to Mercedes-Benz vehicles.

10.1. Expert Advice and Guidance

We offer expert advice and guidance on choosing the right diagnostic tools for your needs. Our team of experienced technicians can help you select the best OBD2 scanner or advanced diagnostic tool for your Mercedes-Benz.

10.2. Comprehensive Diagnostic Information

Our website provides comprehensive diagnostic information for Mercedes-Benz vehicles. We cover a wide range of topics, from basic OBD2 scanning to advanced brake system diagnostics.

10.3. Step-by-Step Repair Guides

We offer step-by-step repair guides that can help you perform common maintenance and repair tasks on your Mercedes-Benz. Our guides are written by experienced technicians and are easy to follow.

10.4. Community Support

Join our community of Mercedes-Benz owners and enthusiasts. Share your experiences, ask questions, and get advice from other members.

10.5. Contact Us for Personalized Assistance

If you need personalized assistance, don’t hesitate to contact us. Our team is here to help you with all your Mercedes-Benz diagnostic and repair needs.

Full System Car Scanner | Foxwell

Full System Car Scanner | Foxwell

In conclusion, while an OBD2 scanner is a valuable tool for diagnosing electronic issues in your car, it cannot detect mechanical problems like brake cylinder failure. Recognizing the symptoms of brake cylinder issues, performing regular inspections, and seeking professional service when needed are essential for maintaining your brake system and ensuring your safety on the road. Trust MERCEDES-DIAGNOSTIC-TOOL.EDU.VN to provide you with the knowledge and tools you need to keep your Mercedes-Benz running smoothly.

Ready to take control of your Mercedes-Benz diagnostics and maintenance? Contact us today for expert advice, personalized assistance, and access to our comprehensive resources. Visit MERCEDES-DIAGNOSTIC-TOOL.EDU.VN or call us at +1 (641) 206-8880. Our address is 789 Oak Avenue, Miami, FL 33101, United States. Let us help you keep your Mercedes-Benz in top condition.

FAQs

1. Will an OBD2 scanner tell which cylinder is misfiring?

Yes, an OBD2 scanner can identify a misfiring cylinder by reading specific fault codes (like P0300 for random misfires or P0301-P0308 for individual cylinders). It will provide the cylinder number and help you pinpoint the issue. These codes can help mechanics and car owners diagnose and address engine problems more effectively.

2. Will an OBD2 scanner read brake codes?

Yes, but only for electronic systems like ABS (Anti-lock Braking System). It can read brake-related codes if there’s an issue with sensors or electrical components. However, it won’t detect mechanical problems like brake cylinder failure. This limitation highlights the importance of combining electronic diagnostics with physical inspections for a comprehensive assessment.

3. What problems can OBD2 detect?

OBD2 scanners can detect a variety of problems related to the car’s electronic systems, including engine issues, emissions system faults, sensor malfunctions, ABS errors, airbag (SRS) problems, and more. It’s best suited for electrical diagnostics rather than mechanical issues. Understanding these capabilities allows car owners to address electronic issues promptly.

4. Can an OBD2 scanner detect low brake fluid?

No, an OBD2 scanner cannot directly detect low brake fluid. Low brake fluid is typically a mechanical issue, often related to leaks or worn brake pads, which are not monitored by the car’s electronic sensors. The scanner is designed to read electronic signals and sensor data, not fluid levels.

5. Can an OBD2 scanner detect a bad master cylinder?

While an OBD2 scanner cannot directly detect a bad master cylinder, it may indirectly indicate a problem if the master cylinder failure affects an electronic component. For example, if a failing master cylinder causes issues with the ABS system, the scanner may read ABS fault codes. However, a physical inspection is usually required to diagnose a bad master cylinder.

6. How often should I check my brake cylinders?

You should check your brake cylinders at least once a year, or more frequently if you notice any symptoms of brake problems. Regular inspections can help identify issues early, preventing more severe damage and ensuring your safety on the road.

7. What are the signs of a leaking brake cylinder?

The signs of a leaking brake cylinder include brake fluid leaks near the wheels, a soft or spongy brake pedal, reduced braking power, and a delayed brake response. If you notice any of these symptoms, it’s crucial to inspect your brake system and address any issues promptly.

8. Can I replace a brake cylinder myself?

Replacing a brake cylinder can be a DIY project if you have the necessary skills and tools. However, it’s essential to follow proper procedures and safety precautions. If you’re not comfortable performing the repair yourself, it’s best to seek professional assistance.

9. What is the cost of replacing a brake cylinder?

The cost of replacing a brake cylinder can vary depending on the make and model of your car, as well as the location of the repair shop. On average, the cost can range from $200 to $500, including parts and labor.

10. How can I prevent brake cylinder problems?

You can prevent brake cylinder problems by performing regular brake system maintenance, including checking and flushing the brake fluid, inspecting brake pads and rotors, and lubricating brake components. Following the manufacturer’s recommendations for brake system maintenance is also essential.