The OBD2 connector serves as your vehicle’s self-diagnostic gateway, offering standardized access to diagnostic trouble codes (DTCs) and real-time data. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we specialize in providing comprehensive solutions for Mercedes-Benz diagnostics, including in-depth knowledge of the OBD2 connector and its applications. Our expertise will guide you through understanding, utilizing, and troubleshooting your Mercedes using OBD2 technology, ensuring optimal vehicle performance and maintenance. This guide will cover diagnostic tools, data logging, and automotive repair.

Contents

- 1. Understanding the OBD2 Connector

- 1.1. What is OBD2?

- 1.2. History and Evolution of OBD2

- 1.3. Does My Car Support OBD2?

- 1.4. The OBD2 Connector Pinout [SAE J1962]

- 1.5. OBD2 Connector Type A vs. B

- 2. Key Components of the OBD2 System

- 2.1. Diagnostic Scan Tools

- 2.2. Communication Protocols

- 2.3. OBD2 and CAN Bus [ISO 15765-4]

- 3. Using the OBD2 Connector for Diagnostics

- 3.1. Reading and Interpreting Diagnostic Trouble Codes (DTCs)

- 3.2. Monitoring Real-Time Data

- 3.3. Performing Diagnostic Tests

- 4. Opening Hidden Features

- 4.1 Benefits of Unlocking Hidden Features

- 4.2 Popular Hidden Features

- 4.3 Process of Opening Hidden Features Using the OBD2 Connector

- 5. The Future of OBD2

- 5.1. OBD3 and Telematics

- 5.2. Alternatives: WWH-OBD and OBDonUDS

- 5.3. Challenges and Opportunities

- 6. Practical Tips for Using the OBD2 Connector

- 6.1. Choosing the Right Diagnostic Tool

- 6.2. Understanding OBD2 Modes and PIDs

- 6.3. Safe Practices and Precautions

- 7. OBD2 Data Logging

- 7.1. How to Log and Decode OBD2 Data

- 7.1.1. Test Bit-Rate, IDs & Supported PIDs

- 7.1.2. Configure OBD2 PID Requests

- 7.2. Tools and Software for Data Analysis

- 7.3. Interpreting Logged Data

- 7.4. OBD2 Data Logging – Use Case Examples

- 8. Common Issues and Troubleshooting

- 8.1. Identifying Connection Problems

- 8.2. Addressing Inaccurate Data

- 8.3. Resolving Communication Errors

- 9. Maximizing the Benefits with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 9.1. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Assist You

- 9.2. Contact Us for Expert Advice

- 10. Frequently Asked Questions (FAQs)

1. Understanding the OBD2 Connector

The OBD2 connector, or On-Board Diagnostics II connector, is a standardized interface used to access a vehicle’s self-diagnostic system. It allows technicians and vehicle owners to retrieve diagnostic trouble codes (DTCs) and real-time data, providing valuable insights into the vehicle’s health and performance.

1.1. What is OBD2?

OBD2 is a vehicle’s built-in self-diagnostic system. It’s a standardized protocol that enables extraction of diagnostic trouble codes (DTCs) and real-time data via the OBD2 connector. The malfunction indicator light on your dashboard indicates an issue, prompting a mechanic to use an OBD2 scanner connected to the 16-pin OBD2 connector to diagnose the problem. The tool sends ‘OBD2 requests’ to the car, which responds with data like speed, fuel level, or DTCs.

The image shows the malfunction indicator light (MIL) and the OBD2 scan tool.

1.2. History and Evolution of OBD2

The OBD2 system originated in California, driven by the California Air Resources Board (CARB), which mandated OBD in all new cars from 1991 onward for emission control. The Society of Automotive Engineers (SAE) recommended the OBD2 standard, which standardized DTCs and the OBD connector across manufacturers, documented under SAE J1962.

- 1996: OBD2 becomes mandatory in the USA for cars and light trucks.

- 2001: Required in the EU for gasoline cars.

- 2003: Required in the EU for diesel cars (EOBD).

- 2005: OBD2 required in the US for medium-duty vehicles.

- 2008: US cars must use ISO 15765-4 (CAN) as the OBD2 basis.

- 2010: OBD2 required in US heavy-duty vehicles.

A graphic illustrates the history of OBD2 and its emission control functions.

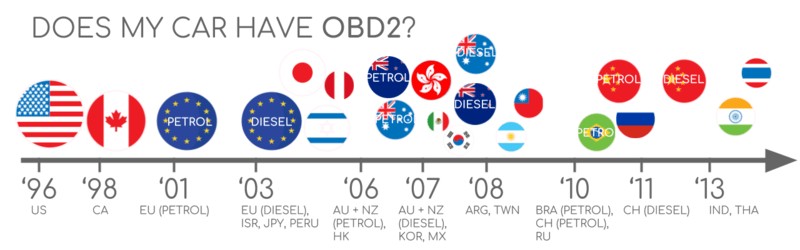

1.3. Does My Car Support OBD2?

Almost all newer non-electric cars support OBD2, typically running on CAN bus. Older cars may have a 16-pin OBD2 connector but might not fully support OBD2. Compliance can be determined by the vehicle’s purchase location and date.

Does My Car Have OBD2?

Does My Car Have OBD2?

A table showing compliance dates for OBD2 in different regions.

1.4. The OBD2 Connector Pinout [SAE J1962]

The 16-pin OBD2 connector facilitates easy data access, as specified in SAE J1962 / ISO 15031-3. This connector, also known as the Data Link Connector (DLC), is usually located near the steering wheel, though it may be hidden. Pin 16 provides battery power even when the ignition is off. The pinout configuration depends on the communication protocol, with CAN bus being the most common, utilizing pins 6 (CAN-H) and 14 (CAN-L).

The image shows the pinout diagram for an OBD2 connector.

1.5. OBD2 Connector Type A vs. B

Two common OBD2 connector types exist: Type A, found in cars, and Type B, used in medium and heavy-duty vehicles. While the OBD2 pinouts are similar, they differ in power supply outputs (12V for Type A and 24V for Type B). Baud rates also vary, with cars typically using 500K, while heavy-duty vehicles often use 250K (though 500K support is increasing). Type B connectors feature an interrupted groove in the middle, making a Type B OBD2 adapter cable compatible with both types, while a Type A cable will not fit into a Type B socket.

A visual comparison between OBD2 Connector Type A and Type B.

2. Key Components of the OBD2 System

The OBD2 system comprises several key components, including the connector itself, diagnostic tools, and the communication protocols that enable data exchange between the vehicle and external devices.

2.1. Diagnostic Scan Tools

Diagnostic scan tools are essential for accessing and interpreting data from the OBD2 connector. These tools range from basic code readers to advanced diagnostic platforms, each offering varying levels of functionality and compatibility. Basic code readers can retrieve DTCs, while advanced tools can perform in-depth diagnostics, live data streaming, and bi-directional control.

2.2. Communication Protocols

Communication protocols govern data exchange between the vehicle and diagnostic tools. Since 2008, CAN bus has been the mandatory lower-layer protocol for OBD2 in all cars sold in the US, as per ISO 15765. Older cars may use other protocols like ISO 14230-4 (KWP2000), ISO 9141-2, SAE J1850 (VPW), and SAE J1850 (PWM).

2.3. OBD2 and CAN Bus [ISO 15765-4]

Since 2008, CAN bus has been the mandatory lower-layer protocol for OBD2 in all cars sold in the US, compliant with ISO 15765. ISO 15765-4 (Diagnostics over CAN or DoCAN) standardizes the CAN interface for test equipment, focusing on the physical, data link, and network layers. Key specifications include bit-rates of 250K or 500K, 11-bit or 29-bit CAN IDs, specific CAN IDs for OBD requests/responses, a diagnostic CAN frame data length of 8 bytes, and a maximum OBD2 adapter cable length of 5 meters.

An illustration showing the relationship between OBD2 and CAN bus.

3. Using the OBD2 Connector for Diagnostics

The primary function of the OBD2 connector is to facilitate vehicle diagnostics. By connecting a diagnostic tool to the OBD2 connector, users can retrieve DTCs, monitor real-time data, and perform various diagnostic tests.

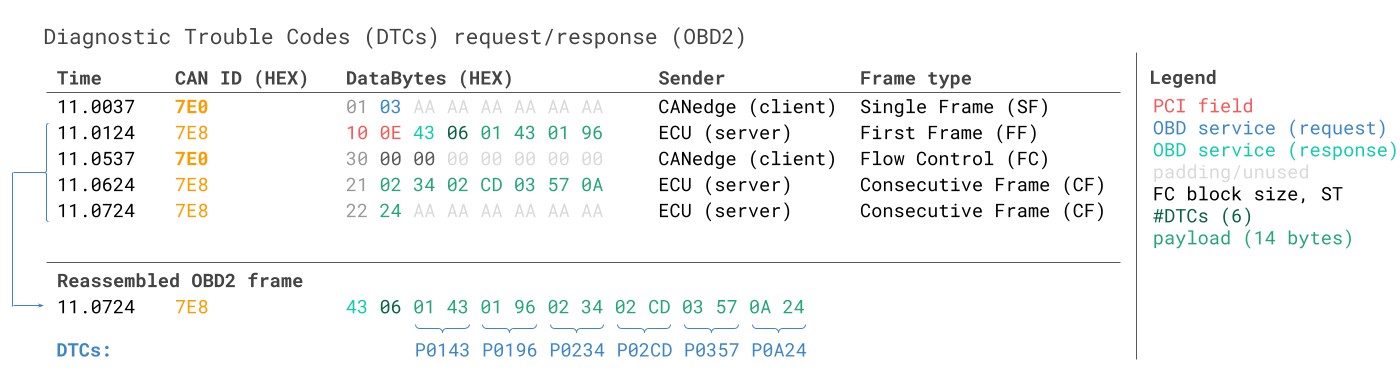

3.1. Reading and Interpreting Diagnostic Trouble Codes (DTCs)

DTCs are standardized codes that indicate specific issues within the vehicle’s systems. Each code consists of a letter followed by four digits, providing information about the affected system and the nature of the problem. Understanding how to read and interpret DTCs is crucial for effective vehicle diagnostics and repair.

3.2. Monitoring Real-Time Data

The OBD2 connector allows users to monitor real-time data, providing insights into various parameters such as engine speed, coolant temperature, fuel consumption, and more. Monitoring real-time data can help identify performance issues, diagnose sensor malfunctions, and assess the overall health of the vehicle.

3.3. Performing Diagnostic Tests

Advanced diagnostic tools can perform various tests through the OBD2 connector, such as actuator tests, sensor calibrations, and system resets. These tests can help pinpoint specific issues, verify repairs, and optimize vehicle performance.

4. Opening Hidden Features

Unlocking hidden features in Mercedes-Benz vehicles can enhance functionality and personalization. The OBD2 connector plays a crucial role in this process, allowing access to various control units and parameters that can be modified to enable these features. While the specific steps and available features may vary depending on the vehicle model and software version, the general process involves connecting a compatible diagnostic tool to the OBD2 connector and navigating to the appropriate control units to make the desired changes.

4.1 Benefits of Unlocking Hidden Features

Unlocking hidden features in Mercedes-Benz vehicles provides a range of benefits, enhancing both the functionality and personalization of the vehicle. These benefits include:

- Enhanced Comfort: Activating features such as automatic folding mirrors, customized climate control settings, and personalized seat adjustments can significantly improve the driving experience, tailoring the vehicle to individual preferences.

- Improved Convenience: Unlocking functions like remote start, enhanced parking assistance, and automatic trunk opening can make daily tasks easier and more convenient, saving time and effort.

- Increased Safety: Enabling advanced safety features such as blind-spot monitoring, lane-keeping assist, and adaptive cruise control can provide additional layers of protection, reducing the risk of accidents and enhancing overall safety.

- Personalized Aesthetics: Customizing interior lighting options, display themes, and sound settings can create a unique and visually appealing environment, reflecting the owner’s personal style and preferences.

4.2 Popular Hidden Features

The specific hidden features available for unlocking vary depending on the Mercedes-Benz model and software version. However, some of the most popular and sought-after features include:

- Automatic Folding Mirrors: Automatically fold the side mirrors when the vehicle is locked, preventing damage in tight parking spaces.

- Comfort Closing: Close all windows and the sunroof with a single button press on the remote key.

- Enhanced Ambient Lighting: Customize the color and intensity of the interior ambient lighting to create a personalized atmosphere.

- Sport Displays: Activate sport-themed displays in the instrument cluster and infotainment system, providing a more dynamic and engaging driving experience.

- Acoustic Lock/Unlock Confirmation: Enable an audible beep or chime when the vehicle is locked or unlocked, providing clear confirmation of the action.

- Video in Motion: Allow video playback on the infotainment screen while the vehicle is in motion (may be restricted in some regions for safety reasons).

4.3 Process of Opening Hidden Features Using the OBD2 Connector

Unlocking hidden features in Mercedes-Benz vehicles using the OBD2 connector involves a systematic approach that requires the right tools, knowledge, and precautions. The general process includes:

- Preparation: Gather the necessary tools, including a compatible diagnostic tool, software, and a stable power supply to prevent interruptions during the process.

- Connection: Connect the diagnostic tool to the vehicle’s OBD2 connector, ensuring a secure and stable connection.

- Identification: Identify the specific control units and parameters that need to be modified to unlock the desired features. This may involve consulting online resources, forums, or professional guides.

- Backup: Create a backup of the original control unit settings to ensure that you can revert to the previous configuration if anything goes wrong.

- Modification: Carefully modify the parameters using the diagnostic tool, following the instructions provided by the software or guide.

- Verification: Verify that the modifications have been successfully applied and that the unlocked features are functioning correctly.

- Testing: Test the unlocked features thoroughly to ensure that they work as expected and do not interfere with other vehicle systems.

Disclaimer: Modifying vehicle settings can have unintended consequences. Always proceed with caution and consult with a professional if you are unsure about any aspect of the process.

OBD2 Diagnostic Trouble Codes DTC CAN Bus Request Response Example

OBD2 Diagnostic Trouble Codes DTC CAN Bus Request Response Example

5. The Future of OBD2

The OBD2 protocol is evolving to meet the demands of modern vehicles. Trends include the development of OBD3, which adds telematics to all cars for remote diagnostics and emissions testing, and alternatives like WWH-OBD and OBDonUDS, which streamline and enhance OBD communication using the UDS protocol.

5.1. OBD3 and Telematics

OBD3 aims to add a small radio transponder to all cars, enabling the vehicle identification number (VIN) and DTCs to be sent via WiFi to a central server for checks. This facilitates remote emission control checks, saving costs and increasing convenience, though it raises privacy and security concerns.

5.2. Alternatives: WWH-OBD and OBDonUDS

Modern alternatives to OBD2 include WWH-OBD (World Wide Harmonized OBD) and OBDonUDS (OBD on UDS). These protocols enhance OBD communication by using the UDS protocol as a foundation.

5.3. Challenges and Opportunities

The future of OBD2 faces challenges such as data access restrictions by manufacturers, particularly for electric vehicles, and security concerns related to car hacking. However, it also presents opportunities for innovative third-party services and applications that leverage OBD2 data for vehicle monitoring, diagnostics, and performance optimization.

A graphic representing the challenge of accessing data in electric vehicles.

6. Practical Tips for Using the OBD2 Connector

To maximize the benefits of using the OBD2 connector, consider these practical tips:

6.1. Choosing the Right Diagnostic Tool

Selecting the appropriate diagnostic tool depends on your needs and budget. Basic code readers are suitable for simple DTC retrieval, while advanced diagnostic platforms offer comprehensive functionality for in-depth diagnostics and testing.

6.2. Understanding OBD2 Modes and PIDs

Familiarize yourself with the various OBD2 modes and parameter IDs (PIDs) to effectively access and interpret vehicle data. Mode 0x01 provides current real-time data, while others are used for DTCs and freeze frame data. Each mode contains PIDs, with mode 0x01 containing approximately 200 standardized PIDs.

6.3. Safe Practices and Precautions

Always follow safe practices when using the OBD2 connector and diagnostic tools. Avoid making changes to vehicle systems without proper knowledge and understanding, and ensure that your diagnostic tool is compatible with your vehicle.

7. OBD2 Data Logging

Data logging is an important aspect of using the OBD2 connector, allowing you to record and analyze vehicle data over time. This can be useful for troubleshooting intermittent issues, monitoring performance, and optimizing fuel efficiency.

7.1. How to Log and Decode OBD2 Data

To log OBD2 data, you can use a CAN bus data logger like the CANedge. Configure the device to transmit custom CAN frames for OBD2 logging and connect it to your vehicle via an OBD2-DB9 adapter cable.

7.1.1. Test Bit-Rate, IDs & Supported PIDs

Test the bit-rate and IDs used by your vehicle using the CANedge. ISO 15765-4 provides recommendations for determining the correct combination.

- Send a CAN frame at 500K and check if successful (else try 250K).

- Use the identified bit-rate for subsequent communication.

- Send multiple ‘Supported PIDs’ requests and review the results.

- Based on response IDs, determine 11-bit vs. 29-bit.

- Based on response data, see what PIDs are supported.

7.1.2. Configure OBD2 PID Requests

Configure your transmit list with PIDs of interest, considering:

- CAN IDs: Shift to ‘Physical Addressing’ request IDs (e.g., 0x7E0) to avoid multiple responses.

- Spacing: Add 300-500 ms between each OBD2 request.

- Battery drain: Use triggers to stop transmitting when the vehicle is inactive.

- Filters: Add filters to only record OBD2 responses.

A diagram illustrating OBD2 PID data logger requests.

7.2. Tools and Software for Data Analysis

Analyze and visualize your data by decoding the raw OBD2 data into ‘physical values.’ Use the ISO 15031-5/SAE J1979 specifications and a free OBD2 DBC file to DBC decode the data in CAN bus software tools.

7.3. Interpreting Logged Data

Interpret the logged data to identify trends, diagnose issues, and optimize vehicle performance. Look for anomalies, correlations, and patterns that provide insights into the vehicle’s health and operation.

7.4. OBD2 Data Logging – Use Case Examples

- Logging Data from Cars: Reduce fuel costs, improve driving habits, and test prototype parts.

- Real-Time Car Diagnostics: Stream human-readable OBD2 data in real-time for diagnosing vehicle issues.

- Predictive Maintenance: Monitor cars and light trucks via IoT OBD2 loggers to predict and avoid breakdowns.

- Vehicle Blackbox Logger: Use an OBD2 logger as a ‘blackbox’ for vehicles, providing data for disputes or diagnostics.

A visual representation of an OBD2 data logger in a car.

8. Common Issues and Troubleshooting

While the OBD2 system is robust, users may encounter common issues. These can include connection problems, inaccurate data, and communication errors.

8.1. Identifying Connection Problems

If you cannot connect to the OBD2 system, check the connector for damage, ensure that the diagnostic tool is properly connected, and verify that the vehicle’s ignition is turned on.

8.2. Addressing Inaccurate Data

Inaccurate data may result from sensor malfunctions, communication errors, or incorrect diagnostic tool settings. Verify the accuracy of the data by comparing it to other sources, and consult the vehicle’s service manual for troubleshooting guidance.

8.3. Resolving Communication Errors

Communication errors can occur due to protocol mismatches, wiring issues, or faulty diagnostic tools. Verify that the diagnostic tool supports the vehicle’s communication protocol, check the wiring for damage, and try using a different diagnostic tool.

9. Maximizing the Benefits with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer specialized solutions and support for Mercedes-Benz diagnostics. Our services include:

- Expert Guidance: Providing detailed information about diagnostic tools, unlocking hidden features, and repair guidelines tailored for Mercedes-Benz vehicles.

- Step-by-Step Instructions: Offering clear, easy-to-follow instructions for using diagnostic tools, opening hidden features, and performing basic repairs and maintenance.

- Professional Support: Answering your questions and providing immediate assistance for any concerns related to Mercedes-Benz vehicle care and repair.

9.1. How MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Can Assist You

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can assist you in diagnosing, repairing, and maintaining your Mercedes-Benz vehicle. Our comprehensive resources and expert support enable you to take control of your vehicle’s care and optimize its performance.

9.2. Contact Us for Expert Advice

For expert advice on Mercedes-Benz diagnostics, maintenance, and unlocking hidden features, contact us today. Our team of experienced technicians and specialists is ready to assist you.

10. Frequently Asked Questions (FAQs)

1. What is the OBD2 connector?

The OBD2 connector is a standardized interface used to access a vehicle’s self-diagnostic system, allowing retrieval of diagnostic trouble codes (DTCs) and real-time data.

2. Where is the OBD2 connector located in my Mercedes-Benz?

The OBD2 connector is typically located under the dashboard on the driver’s side, near the steering wheel. However, the exact location may vary depending on the model.

3. What types of diagnostic tools can I use with the OBD2 connector?

You can use a range of diagnostic tools, from basic code readers to advanced diagnostic platforms, depending on your diagnostic needs.

4. How do I read and interpret diagnostic trouble codes (DTCs)?

Connect a diagnostic tool to the OBD2 connector, retrieve the DTCs, and consult a DTC lookup tool or service manual to understand the meaning of each code.

5. Can I monitor real-time data using the OBD2 connector?

Yes, the OBD2 connector allows you to monitor real-time data such as engine speed, coolant temperature, fuel consumption, and more.

6. Is it safe to perform diagnostic tests using the OBD2 connector?

Yes, but it is essential to follow safe practices and precautions. Avoid making changes to vehicle systems without proper knowledge and understanding.

7. What are some common issues I might encounter when using the OBD2 connector?

Common issues include connection problems, inaccurate data, and communication errors. Follow troubleshooting steps to resolve these issues.

8. How can I unlock hidden features in my Mercedes-Benz using the OBD2 connector?

Connect a compatible diagnostic tool to the OBD2 connector and navigate to the appropriate control units to modify parameters and enable hidden features.

9. What is OBD3, and how will it affect vehicle diagnostics?

OBD3 adds telematics to all cars for remote diagnostics and emissions testing, potentially changing how vehicle diagnostics are performed.

10. How can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN assist me with my Mercedes-Benz diagnostics?

We offer specialized solutions, expert guidance, and comprehensive support for Mercedes-Benz diagnostics, maintenance, and unlocking hidden features.

By understanding the OBD2 connector and its capabilities, you can take control of your Mercedes-Benz diagnostics and maintenance. Visit MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information and expert support. Contact us at 789 Oak Avenue, Miami, FL 33101, United States, or via Whatsapp at +1 (641) 206-8880.

Call to Action:

Ready to take control of your Mercedes-Benz diagnostics, unlock hidden features, or need expert guidance on vehicle maintenance? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for a consultation. Our expert team is ready to assist you with all your Mercedes-Benz diagnostic needs. Reach out now via Whatsapp at +1 (641) 206-8880 or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN. Let us help you keep your Mercedes-Benz running at its best!