Different Types Of Obd2 Ports facilitate access to your vehicle’s diagnostic information. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers expert insights and tools to help you understand and utilize these ports effectively. Understanding the nuances of OBD2 ports is critical for Mercedes-Benz owners and technicians for efficient vehicle maintenance and diagnostics. Dive in to explore OBD2 port variations, compatibility, and advanced diagnostic techniques.

Contents

- 1. Understanding OBD2 Ports: An Overview

- 2. Historical Context of OBD2

- 3. Types of OBD2 Connectors: A Detailed Look

- 3.1. Type A OBD2 Connector

- 3.2. Type B OBD2 Connector

- 3.3. Differentiating Type A and Type B

- 4. OBD2 Port Pinout and Communication Protocols

- 4.1. Standard OBD2 Pinout (SAE J1962)

- 4.2. Common Communication Protocols

- 4.3. OBD2 and CAN Bus

- 5. Decoding OBD2 Data

- 5.1. Structure of an OBD2 Message

- 5.2. OBD2 Modes

- 5.3. Parameter IDs (PIDs)

- 5.4. Example: Requesting Vehicle Speed

- 5.5. Using OBD2 PID Overview Tools

- 6. Advanced OBD2 Techniques: ISO-TP and Multi-Frame Communication

- 6.1. ISO-TP (ISO 15765-2)

- 6.2. Multi-Frame Examples

- 6.3. Extracting the Vehicle Identification Number (VIN)

- 6.4. Diagnostic Trouble Codes (DTCs)

- 7. The Future of OBD2

- 7.1. OBD3 and Telematics

- 7.2. WWH-OBD and OBDonUDS

- 7.3. Challenges with Electric Vehicles (EVs)

- 8. Practical Applications and Use Cases

- 8.1. Personal Vehicle Maintenance

- 8.2. Fleet Management

- 8.3. Insurance and Black Box Logging

- 9. Choosing the Right OBD2 Tool for Your Needs

- 9.1. Basic OBD2 Scanners

- 9.2. Advanced OBD2 Scanners

- 9.3. OBD2 Data Loggers

- 10. Maximizing Your OBD2 Experience with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 10.1. Expert Guidance

- 10.2. Comprehensive Resources

- 10.3. Cutting-Edge Tools

- FAQ: Decoding OBD2 Ports

- 1. What is an OBD2 port?

- 2. Where is the OBD2 port located in my car?

- 3. What types of vehicles support OBD2?

- 4. What is the difference between Type A and Type B OBD2 connectors?

- 5. What communication protocols do OBD2 systems use?

- 6. How can I decode OBD2 data?

- 7. What are OBD2 modes and PIDs?

- 8. What is ISO-TP, and why is it important for OBD2?

- 9. Can I use OBD2 on an electric vehicle?

- 10. What is the future of OBD2?

- Conclusion

1. Understanding OBD2 Ports: An Overview

On-Board Diagnostics II (OBD2) ports are standardized interfaces that provide access to a vehicle’s self-diagnostic data. These ports enable users to retrieve diagnostic trouble codes (DTCs) and real-time data. They are crucial for troubleshooting and maintaining vehicle health.

- OBD2 ports act as gateways to your vehicle’s internal systems, providing invaluable data for maintenance and repair.

- The standardization of OBD2 ports has simplified vehicle diagnostics. It allows any compliant tool to interface with any compatible vehicle.

- Understanding OBD2 protocols enables technicians and car enthusiasts to diagnose and address issues. It promotes informed vehicle maintenance.

2. Historical Context of OBD2

The evolution of OBD2 began in California. The California Air Resources Board (CARB) mandated OBD in all new cars from 1991 for emission control. This regulation led to the development of a standardized system.

- 1996: OBD2 became mandatory in the USA for cars and light trucks, marking a significant milestone.

- 2001: The European Union required OBD for gasoline cars, expanding its adoption.

- 2003: OBD was also mandated for diesel cars in the EU (EOBD), ensuring comprehensive diagnostic coverage.

- 2005: The USA extended OBD2 requirements to medium-duty vehicles.

- 2008: US cars were required to use ISO 15765-4 (CAN) as the OBD2 foundation, standardizing communication.

- 2010: OBD2 became mandatory for heavy-duty vehicles in the USA.

This timeline highlights the progressive integration of OBD2 across various vehicle types and regions.

3. Types of OBD2 Connectors: A Detailed Look

OBD2 connectors come in different types, each designed to meet specific vehicle requirements. Understanding these variations is crucial for compatibility and effective diagnostics.

3.1. Type A OBD2 Connector

The Type A connector is commonly found in cars and light-duty vehicles. It operates on a 12V power supply.

- Typical Usage: Cars, light trucks, and standard passenger vehicles.

- Voltage: 12V power supply.

- Key Features: Standardized pinout for broad compatibility.

3.2. Type B OBD2 Connector

The Type B connector is typically used in medium and heavy-duty vehicles. It utilizes a 24V power supply.

- Typical Usage: Trucks, buses, and heavy machinery.

- Voltage: 24V power supply.

- Key Features: An interrupted groove in the middle distinguishes it from Type A.

3.3. Differentiating Type A and Type B

Type A and Type B connectors differ mainly in their voltage and physical design.

| Feature | Type A Connector | Type B Connector |

|---|---|---|

| Typical Usage | Cars, Light Trucks | Heavy Duty Vehicles |

| Voltage | 12V | 24V |

| Groove | Continuous | Interrupted |

A Type B adapter cable is compatible with both Type A and Type B sockets, while a Type A cable will not fit into a Type B socket.

4. OBD2 Port Pinout and Communication Protocols

The OBD2 port pinout is standardized, ensuring uniform access to vehicle data. However, the communication protocol can vary, affecting the type of data accessible.

4.1. Standard OBD2 Pinout (SAE J1962)

The OBD2 connector has 16 pins, each serving a specific function. Key pins include:

- Pin 4: Chassis Ground

- Pin 5: Signal Ground

- Pin 6: CAN High (CAN-H)

- Pin 7: ISO 9141-2 K-line

- Pin 10: SAE J1850 Bus –

- Pin 14: CAN Low (CAN-L)

- Pin 15: ISO 9141-2 L-line

- Pin 16: Battery Power

4.2. Common Communication Protocols

Several communication protocols are used in OBD2 systems, each with its own characteristics.

- CAN (ISO 15765): Mandatory in US cars since 2008, CAN is the most common protocol.

- KWP2000 (ISO 14230-4): The Keyword Protocol 2000 was used in many 2003+ cars, particularly in Asia.

- ISO 9141-2: Utilized in European, Chrysler, and Asian cars from 2000-2004.

- SAE J1850 VPW: Predominantly used in older General Motors vehicles.

- SAE J1850 PWM: Mainly found in older Ford vehicles.

4.3. OBD2 and CAN Bus

Since 2008, CAN bus has been mandatory for OBD2 in all US cars under ISO 15765.

- CAN Bus Bit-Rate: Must be either 250K or 500K.

- CAN IDs: Can be 11-bit or 29-bit.

- Diagnostic CAN Frame Data Length: Must be 8 bytes.

- OBD2 Adapter Cable Length: Maximum 5 meters.

The CAN protocol standardizes the interface, focusing on physical, data link, and network layers.

5. Decoding OBD2 Data

Decoding OBD2 data involves understanding the structure of OBD2 messages and using appropriate tools to interpret the data.

5.1. Structure of an OBD2 Message

An OBD2 message consists of an identifier, data length, and data. The data is divided into Mode, Parameter ID (PID), and data bytes.

- Mode: Indicates the type of data being requested or provided (e.g., real-time data, DTCs).

- PID: Specifies the particular parameter being requested or reported (e.g., speed, RPM).

- Data Bytes: The actual values associated with the requested parameter.

5.2. OBD2 Modes

There are 10 standardized OBD2 diagnostic services (modes). Each mode serves a different purpose.

- Mode 0x01: Shows current real-time data.

- Modes 0x02, 0x03, 0x04: Used to display and clear diagnostic trouble codes (DTCs).

- Mode 0x09: Requests vehicle information, such as the VIN.

Vehicles do not have to support all OBD2 modes, and they may include OEM-specific modes beyond the standardized ones.

5.3. Parameter IDs (PIDs)

Each OBD2 mode contains Parameter IDs (PIDs). For example, Mode 0x01 includes around 200 standardized PIDs with real-time data.

- PID 0x00 (Mode 0x01): Determines which PIDs (0x01-0x20) the vehicle supports.

- PIDs 0x20, 0x40, …, 0xC0: Used to check support for remaining Mode 0x01 PIDs.

5.4. Example: Requesting Vehicle Speed

An external tool sends a request message with CAN ID 0x7DF, including Mode 0x01 and PID 0x0D (Vehicle Speed).

The car responds with CAN ID 0x7E8, providing the vehicle speed value. For instance, a value of 0x32 (50 in decimal) indicates a speed of 50 km/h.

5.5. Using OBD2 PID Overview Tools

Tools like the OBD2 PID overview provide scaling information for standard PIDs. This helps convert data into physical values.

- SAE J1979 and ISO 15031-5: Provide scaling details for standard PIDs.

- Online Tools: Several online tools simplify the process of constructing request frames and decoding responses.

6. Advanced OBD2 Techniques: ISO-TP and Multi-Frame Communication

For data exceeding 8 bytes, OBD2 uses ISO-TP (ISO 15765-2). This protocol enables multi-frame communication for extracting VINs or DTCs.

6.1. ISO-TP (ISO 15765-2)

ISO-TP is a transport protocol used for communicating large payloads on the CAN bus.

- Segmentation: Divides large data into smaller segments for transmission.

- Flow Control: Manages the flow of data between the sender and receiver.

- Reassembly: Reconstructs the original data from the received segments.

6.2. Multi-Frame Examples

Multi-frame communication is essential for retrieving data like the VIN or multiple DTCs.

- Vehicle Identification Number (VIN): Requires Mode 0x09 and PID 0x02.

- Diagnostic Trouble Codes (DTCs): Uses Mode 0x03 to request emissions-related DTCs.

- Multi-PID Request (6x):External tools request multiple OBD2 PIDs in a single frame, gathering OBD2 data efficiently.

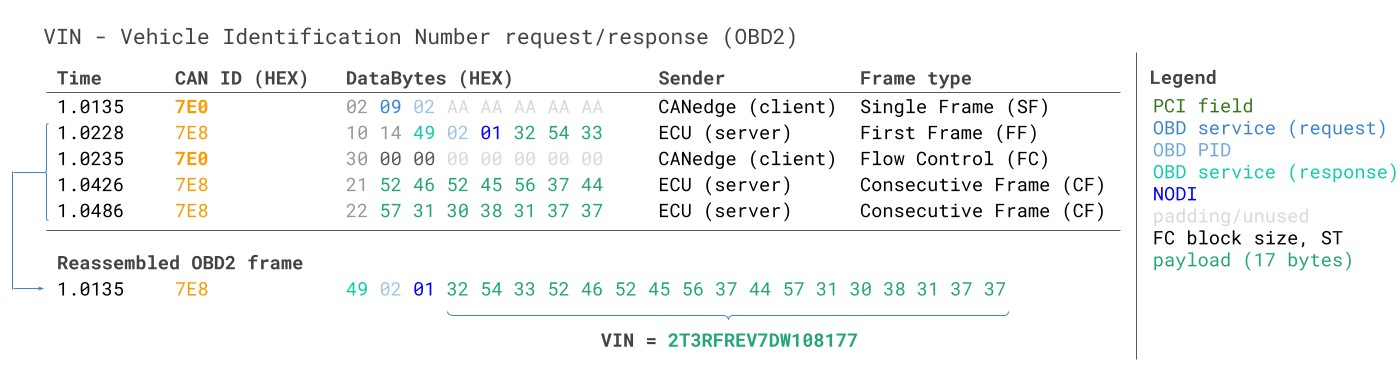

6.3. Extracting the Vehicle Identification Number (VIN)

To extract the VIN, the tester tool sends a Single Frame request with the PCI field (0x02), service identifier (0x09), and PID (0x02). The vehicle responds with a First Frame containing the PCI, length, mode (0x49), and PID (0x02). The VIN follows the PID and can be translated from HEX to ASCII.

VIN Vehicle Identification Number OBD2 Example multi-frame

VIN Vehicle Identification Number OBD2 Example multi-frame

6.4. Diagnostic Trouble Codes (DTCs)

DTCs are retrieved using mode 0x03. The ECU responds with the number of stored DTCs, with each DTC taking up 2 bytes. The 2-byte DTC value is split into a category and a 4-digit code. Decoded DTC values can be found in OBD2 DTC lookup tools.

7. The Future of OBD2

The future of OBD2 involves advancements in technology and changes in regulatory requirements.

7.1. OBD3 and Telematics

OBD3 aims to add telematics to all cars, enabling remote diagnostics and emissions testing.

- Telematics Integration: Includes a small radio transponder for sending VIN and DTCs via WiFi to a central server.

- Remote Monitoring: Facilitates continuous monitoring of vehicle health and emissions.

- Challenges: Concerns about surveillance and data privacy need to be addressed.

7.2. WWH-OBD and OBDonUDS

Modern alternatives like WWH-OBD (World Wide Harmonized OBD) and OBDonUDS (OBD on UDS) seek to enhance OBD communication by using the UDS protocol.

- WWH-OBD: Streamlines OBD communication using UDS as a base.

- OBDonUDS: Leverages UDS for enhanced diagnostic services.

- Benefits: Improved data richness and more efficient communication.

7.3. Challenges with Electric Vehicles (EVs)

Electric vehicles often do not support standard OBD2 protocols. Instead, they use OEM-specific UDS communication.

- OEM-Specific Protocols: Require reverse engineering to decode data.

- Limited Standard OBD2 Support: Most EVs do not support standard OBD2 requests.

- Reverse Engineering: Necessary for decoding data from EVs.

This shift requires new approaches to accessing and interpreting vehicle data.

8. Practical Applications and Use Cases

OBD2 data can be used in a variety of applications. These range from personal vehicle maintenance to industrial fleet management.

8.1. Personal Vehicle Maintenance

Car owners can use OBD2 scanners to diagnose issues and perform maintenance. This prevents costly repairs.

- DIY Diagnostics: Identify and address minor issues before they escalate.

- Performance Monitoring: Track vehicle performance metrics in real-time.

- Fuel Efficiency: Monitor and optimize fuel consumption.

8.2. Fleet Management

OBD2 data helps fleet managers monitor vehicle health, optimize routes, and reduce costs.

- Predictive Maintenance: Detect potential issues before they lead to breakdowns.

- Driver Behavior Monitoring: Track driving habits to improve safety and efficiency.

- Route Optimization: Analyze vehicle data to optimize routes and reduce fuel consumption.

8.3. Insurance and Black Box Logging

OBD2 loggers serve as black boxes for vehicles, providing data for disputes, diagnostics, and insurance claims.

- Accident Reconstruction: Provide detailed data for accident analysis.

- Warranty Compliance: Monitor vehicle usage to ensure warranty compliance.

- Theft Recovery: Track vehicle location and usage patterns.

9. Choosing the Right OBD2 Tool for Your Needs

Selecting the right OBD2 tool depends on your specific needs and technical expertise. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can help you navigate the options.

9.1. Basic OBD2 Scanners

Basic scanners are suitable for reading and clearing DTCs.

- Features: Read DTCs, clear DTCs, view freeze frame data.

- Use Case: Simple diagnostics for everyday car owners.

- Pros: Affordable, easy to use.

9.2. Advanced OBD2 Scanners

Advanced scanners offer enhanced features such as real-time data streaming, bi-directional control, and advanced diagnostics.

- Features: Real-time data streaming, bi-directional control, advanced diagnostics, ABS/SRS diagnostics.

- Use Case: Professional technicians and serious car enthusiasts.

- Pros: Comprehensive diagnostics, advanced functionality.

9.3. OBD2 Data Loggers

OBD2 data loggers record vehicle data for later analysis.

- Features: Record OBD2 data, store data on SD card, wireless data transfer.

- Use Case: Fleet management, performance analysis, black box logging.

- Pros: Data recording, detailed analysis capabilities.

10. Maximizing Your OBD2 Experience with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers tools, information, and support. This helps you make the most of your OBD2 diagnostic capabilities.

10.1. Expert Guidance

Our team provides expert guidance on OBD2 tools, protocols, and diagnostic techniques.

- Consultations: Personalized consultations to help you choose the right tools.

- Troubleshooting: Assistance with diagnosing and resolving vehicle issues.

- Training: Educational resources to enhance your diagnostic skills.

10.2. Comprehensive Resources

We offer comprehensive resources, including tutorials, guides, and FAQs. These resources will deepen your understanding of OBD2 systems.

- Tutorials: Step-by-step guides on using OBD2 tools and performing diagnostics.

- Guides: In-depth explanations of OBD2 protocols and techniques.

- FAQs: Answers to common questions about OBD2 systems.

10.3. Cutting-Edge Tools

We provide access to cutting-edge OBD2 tools and technologies. This includes advanced scanners and data loggers.

- Advanced Scanners: High-performance scanners with comprehensive diagnostic capabilities.

- Data Loggers: Robust data loggers for recording and analyzing vehicle data.

- Software Solutions: User-friendly software for decoding and visualizing OBD2 data.

FAQ: Decoding OBD2 Ports

1. What is an OBD2 port?

An OBD2 (On-Board Diagnostics II) port is a standardized interface in vehicles. It provides access to self-diagnostic data, including diagnostic trouble codes (DTCs) and real-time data.

2. Where is the OBD2 port located in my car?

The OBD2 port is typically located near the steering wheel. However, it may be hidden under the dashboard.

3. What types of vehicles support OBD2?

Almost all newer non-electric vehicles support OBD2. The protocol was mandatory in the USA for cars and light trucks since 1996.

4. What is the difference between Type A and Type B OBD2 connectors?

Type A connectors are commonly used in cars and light trucks. They operate on a 12V power supply. Type B connectors are used in medium and heavy-duty vehicles. They use a 24V power supply and have an interrupted groove in the middle.

5. What communication protocols do OBD2 systems use?

Common communication protocols include CAN (ISO 15765), KWP2000 (ISO 14230-4), ISO 9141-2, SAE J1850 VPW, and SAE J1850 PWM.

6. How can I decode OBD2 data?

Decoding OBD2 data involves understanding the OBD2 message structure. You also need to use appropriate tools to convert raw data into physical values. Resources like the OBD2 PID overview tool can help.

7. What are OBD2 modes and PIDs?

OBD2 modes are diagnostic services that specify the type of data being accessed. Parameter IDs (PIDs) are specific parameters within each mode. For example, mode 0x01 shows real-time data, while PID 0x0D refers to vehicle speed.

8. What is ISO-TP, and why is it important for OBD2?

ISO-TP (ISO 15765-2) is a transport protocol used for communicating large payloads on the CAN bus. It enables multi-frame communication for extracting VINs or DTCs.

9. Can I use OBD2 on an electric vehicle?

Electric vehicles often do not support standard OBD2 protocols. They use OEM-specific UDS communication, which requires reverse engineering to decode.

10. What is the future of OBD2?

The future of OBD2 includes OBD3 with telematics, WWH-OBD, and OBDonUDS. These advancements aim to enhance diagnostic capabilities. They also address the challenges posed by electric vehicles.

Conclusion

Understanding the different types of OBD2 ports and their associated technologies is essential for effective vehicle diagnostics and maintenance. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers the expertise, tools, and resources needed to navigate the complexities of OBD2 systems. By leveraging our comprehensive support, you can ensure your Mercedes-Benz remains in optimal condition.

Ready to enhance your vehicle diagnostics capabilities?

Contact us at:

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Let MERCEDES-DIAGNOSTIC-TOOL.EDU.VN assist you in unlocking the full potential of your vehicle’s diagnostic system. Get in touch today and take the first step towards advanced vehicle maintenance.