Fuel injector resistance is a critical factor in engine performance. This article, brought to you by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, delves into Honda OBD2 fuel injector resistance, offering insights into testing, interpreting results, and ensuring optimal performance. Understanding fuel injector diagnostics, maintenance, and OBD2 scanner compatibility is key to a healthy engine.

Contents

- 1: What is Honda OBD2 Fuel Injector Resistance?

- 2: Why is Fuel Injector Resistance Important for Honda Vehicles?

- 2.1: Accurate Fuel Delivery

- 2.2: Engine Performance and Efficiency

- 2.3: Emissions Control

- 2.4: Engine Longevity

- 3: What are the Symptoms of Incorrect Fuel Injector Resistance in a Honda?

- 3.1: Check Engine Light

- 3.2: Poor Fuel Economy

- 3.3: Rough Idling

- 3.4: Misfires

- 3.5: Hesitation During Acceleration

- 3.6: Fuel Leaks

- 4: What is the Standard Resistance Range for Honda OBD2 Fuel Injectors?

- 4.1: High Impedance (Saturated) Injectors

- 4.2: Low Impedance (Peak and Hold) Injectors

- 4.3: Checking the Resistance

- 4.4: Interpreting the Results

- 5: How to Test Fuel Injector Resistance on a Honda Using an OBD2 Scanner?

- 5.1: Retrieving Diagnostic Trouble Codes (DTCs)

- 5.2: Live Data Monitoring

- 5.3: Injector Circuit Testing

- 5.4: Combining OBD2 Data with Multimeter Testing

- 6: What Tools are Needed to Check Fuel Injector Resistance?

- 6.1: Digital Multimeter

- 6.2: Safety Glasses

- 6.3: Gloves

- 6.4: Rags

- 6.5: OBD2 Scanner (Optional)

- 6.6: Vehicle Service Manual

- 7: Step-by-Step Guide to Checking Honda OBD2 Fuel Injector Resistance

- 7.1: Safety Precautions

- 7.2: Locate the Fuel Injectors

- 7.3: Disconnect the Electrical Connectors

- 7.4: Set Up the Multimeter

- 7.5: Measure the Resistance

- 7.6: Compare the Readings

- 7.7: Interpret the Results

- 7.8: Take Corrective Action

- 8: What Causes Fuel Injector Resistance to Change Over Time?

- 8.1: Heat

- 8.2: Vibration

- 8.3: Contamination

- 8.4: Corrosion

- 8.5: Wear and Tear

- 8.6: Electrical Stress

- 9: Can You Clean Fuel Injectors to Restore Proper Resistance?

- 9.1: Cleaning Methods

- 9.2: Impact on Resistance

- 9.3: When Cleaning is Beneficial

- 10: What are the Consequences of Ignoring Incorrect Fuel Injector Resistance?

- 10.1: Reduced Engine Performance

- 10.2: Poor Fuel Economy

- 10.3: Increased Emissions

- 10.4: Damage to Other Components

- 10.5: Engine Failure

- 10.6: Safety Hazards

- FAQ: Honda OBD2 Fuel Injector Resistance

1: What is Honda OBD2 Fuel Injector Resistance?

Honda OBD2 fuel injector resistance refers to the electrical resistance measured across the terminals of a fuel injector in a Honda vehicle equipped with an OBD2 (On-Board Diagnostics II) system. This measurement, typically expressed in ohms (Ω), is vital for diagnosing fuel injector health and proper operation.

Fuel injectors are solenoid valves that spray fuel into the engine’s cylinders. The engine control unit (ECU) energizes the injector’s solenoid, causing it to open and spray fuel. The resistance of the injector coil affects how quickly and efficiently the injector opens and closes. According to Bosch, a leading manufacturer of fuel injection systems, proper injector resistance ensures accurate fuel delivery, which is crucial for optimal engine performance, fuel economy, and emissions control.

- Importance of Resistance: Correct resistance ensures the injector responds properly to signals from the ECU.

- OBD2 Relevance: The OBD2 system monitors injector performance, including resistance, to detect potential issues.

- Measurement Unit: Resistance is measured in ohms (Ω) using a multimeter.

Alt Text: Honda OBD2 fuel injectors showing electrical connectors, highlighting the point of resistance measurement.

2: Why is Fuel Injector Resistance Important for Honda Vehicles?

Fuel injector resistance is paramount in Honda vehicles because it directly influences fuel delivery accuracy and, consequently, engine performance. Deviations from the specified resistance range can lead to a cascade of issues, impacting everything from fuel efficiency to engine longevity.

2.1: Accurate Fuel Delivery

The ECU relies on precise injector operation to deliver the correct amount of fuel for optimal combustion. Injector resistance outside the manufacturer’s specified range can cause the injector to open too slowly or not fully, leading to under-fueling. Conversely, low resistance can cause the injector to stay open too long, resulting in over-fueling.

According to a study by the Society of Automotive Engineers (SAE), accurate fuel delivery within 5% of the target value is crucial for maintaining optimal combustion efficiency and minimizing emissions.

2.2: Engine Performance and Efficiency

Incorrect fuel delivery directly impacts engine performance. Under-fueling can cause hesitation, misfires, and a lack of power, especially during acceleration. Over-fueling can lead to rough idling, poor fuel economy, and increased emissions.

A properly functioning fuel injection system ensures smooth and responsive engine operation, maximizing power output while minimizing fuel consumption. Honda’s VTEC (Variable Valve Timing and Lift Electronic Control) system, for example, relies on precise fuel delivery to optimize performance at different engine speeds.

2.3: Emissions Control

Fuel injector resistance plays a crucial role in emissions control. Inefficient combustion due to improper fuel delivery increases the levels of harmful pollutants, such as hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx). These pollutants contribute to smog and other environmental problems.

The OBD2 system monitors emissions-related components, including fuel injectors, to ensure compliance with environmental regulations. If the system detects a problem with an injector, it will trigger a check engine light and store a diagnostic trouble code (DTC) to alert the driver and technician.

2.4: Engine Longevity

Prolonged operation with faulty fuel injectors can negatively impact engine longevity. Over-fueling can wash oil off cylinder walls, leading to increased wear and tear on piston rings and cylinder bores. Under-fueling can cause excessive heat in the combustion chamber, potentially damaging valves and pistons.

Maintaining proper fuel injector resistance and addressing any issues promptly can help prevent these problems and extend the life of the engine.

- Fuel Delivery: Ensures the correct amount of fuel is delivered for optimal combustion.

- Performance: Impacts engine responsiveness, power, and fuel economy.

- Emissions: Crucial for meeting environmental regulations and reducing pollution.

- Longevity: Prevents engine damage caused by over- or under-fueling.

3: What are the Symptoms of Incorrect Fuel Injector Resistance in a Honda?

Incorrect fuel injector resistance in a Honda can manifest in various symptoms, affecting engine performance, fuel economy, and overall drivability. Recognizing these symptoms is crucial for timely diagnosis and repair.

3.1: Check Engine Light

One of the most common indicators of a problem with the fuel injection system is the illumination of the check engine light. The OBD2 system continuously monitors the performance of the fuel injectors, and if it detects a resistance value outside the specified range, it will trigger the check engine light and store a diagnostic trouble code (DTC).

Common DTCs associated with fuel injector resistance issues include:

- P0201-P0204: Injector Circuit Malfunction – Cylinder 1-4

- P020A-P020D: Injector Circuit Response Time – Cylinder 1-4

- P0261-P0264: Injector Circuit Low – Cylinder 1-4

- P0264-P0267: Injector Circuit High – Cylinder 1-4

Using an OBD2 scanner, such as those offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, can help you retrieve these codes and pinpoint the specific injector causing the problem.

3.2: Poor Fuel Economy

Incorrect fuel injector resistance can significantly impact fuel economy. Over-fueling due to low resistance or leaking injectors will cause the engine to consume more fuel than necessary, resulting in a noticeable decrease in miles per gallon (MPG).

Conversely, under-fueling due to high resistance can also lead to poor fuel economy as the engine struggles to maintain the desired performance level, requiring more throttle input and fuel consumption.

3.3: Rough Idling

A faulty fuel injector can disrupt the smooth operation of the engine, causing it to idle roughly. This is often due to inconsistent fuel delivery to one or more cylinders, leading to an imbalance in the combustion process.

The engine may vibrate excessively, and the RPM may fluctuate erratically. In severe cases, the engine may stall at idle.

3.4: Misfires

Misfires occur when one or more cylinders fail to ignite the air-fuel mixture properly. This can be caused by either over-fueling or under-fueling due to incorrect fuel injector resistance.

Misfires can result in a loss of power, hesitation during acceleration, and a rough-running engine. They can also damage the catalytic converter if left unaddressed.

3.5: Hesitation During Acceleration

If the fuel injectors are not delivering the correct amount of fuel, the engine may hesitate or stumble during acceleration. This is especially noticeable when trying to accelerate quickly or climb a hill.

The engine may feel sluggish and unresponsive, and there may be a delay between pressing the accelerator pedal and the engine responding.

3.6: Fuel Leaks

In some cases, incorrect fuel injector resistance can be associated with physical damage to the injector, leading to fuel leaks. Leaks can occur around the injector seals or from the injector body itself.

Fuel leaks are a serious safety hazard and should be addressed immediately. They can create a fire risk and also damage other engine components.

- Check Engine Light: Illumination of the check engine light with relevant DTCs.

- Fuel Economy: Noticeable decrease in miles per gallon (MPG).

- Rough Idling: Engine vibrates excessively, and RPM fluctuates erratically.

- Misfires: Loss of power, hesitation during acceleration, and a rough-running engine.

- Hesitation: Sluggish and unresponsive engine during acceleration.

- Fuel Leaks: Fuel leaks around the injector seals or from the injector body.

Alt Text: Close-up of a fuel injector with visible fuel leak, emphasizing the potential safety hazard.

4: What is the Standard Resistance Range for Honda OBD2 Fuel Injectors?

The standard resistance range for Honda OBD2 fuel injectors varies depending on the engine type and model year. It’s crucial to consult the vehicle’s service manual or a reliable source like MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for the specific resistance range for your Honda.

However, as a general guideline:

4.1: High Impedance (Saturated) Injectors

Most Honda OBD2 vehicles use high impedance, saturated injectors. These injectors typically have a resistance range of 10-13 ohms. This range is common for many Honda models from the mid-1990s onwards.

4.2: Low Impedance (Peak and Hold) Injectors

Some older Honda models, particularly those from the early to mid-1990s, may use low impedance, peak and hold injectors. These injectors typically have a resistance range of 2-4 ohms. These injectors require a resistor box in the circuit to limit current flow.

4.3: Checking the Resistance

To check the resistance of your Honda’s fuel injectors, you will need a digital multimeter. Follow these steps:

- Disconnect the Injector: Disconnect the electrical connector from the fuel injector.

- Set the Multimeter: Set the multimeter to measure resistance (ohms Ω).

- Measure the Resistance: Place the multimeter probes on the two terminals of the fuel injector.

- Record the Reading: Note the resistance reading displayed on the multimeter.

- Compare to Specification: Compare the reading to the specified resistance range for your vehicle.

4.4: Interpreting the Results

-

Within Range: If the resistance reading falls within the specified range, the injector is likely functioning correctly from an electrical standpoint. However, other issues, such as clogging or mechanical failure, may still be present.

-

Too High: If the resistance reading is significantly higher than the specified range, it indicates a potential open circuit or high resistance within the injector coil. This can prevent the injector from opening properly.

-

Too Low: If the resistance reading is significantly lower than the specified range, it indicates a potential short circuit within the injector coil. This can cause the injector to stay open too long or overheat.

-

Zero or Infinite: A reading of zero ohms indicates a short circuit, while an infinite reading indicates an open circuit. In either case, the injector is faulty and needs to be replaced.

-

High Impedance: Typically 10-13 ohms (most common for OBD2 Hondas).

-

Low Impedance: Typically 2-4 ohms (common for older Hondas with resistor box).

-

Measurement: Use a digital multimeter to measure resistance across the injector terminals.

-

Interpretation: Compare the reading to the specified range for your vehicle.

5: How to Test Fuel Injector Resistance on a Honda Using an OBD2 Scanner?

While an OBD2 scanner cannot directly measure fuel injector resistance, it can provide valuable information about injector performance and help diagnose resistance-related issues. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a range of OBD2 scanners that can assist in this process.

5.1: Retrieving Diagnostic Trouble Codes (DTCs)

The primary way an OBD2 scanner helps diagnose fuel injector resistance issues is by retrieving DTCs. As mentioned earlier, the OBD2 system monitors the performance of the fuel injectors and will store a DTC if it detects a problem.

Using an OBD2 scanner, you can read these codes and identify which injector is causing the problem. Common codes related to injector resistance include P0201-P0204 (Injector Circuit Malfunction) and P0261-P0264 (Injector Circuit Low/High).

5.2: Live Data Monitoring

Some advanced OBD2 scanners offer live data monitoring capabilities. This allows you to view real-time data from various engine sensors, including fuel injector pulse width.

Fuel injector pulse width is the amount of time the injector is open and spraying fuel. By monitoring the pulse width, you can observe whether the injector is being commanded to open for the correct duration.

If the pulse width is abnormally long or short, it could indicate a problem with the injector’s resistance or other electrical issues.

5.3: Injector Circuit Testing

Some OBD2 scanners offer injector circuit testing functions. These tests typically involve activating or deactivating individual injectors and monitoring the engine’s response.

If the engine’s RPM changes significantly when an injector is activated or deactivated, it indicates that the injector is functioning. If there is no change in RPM, it suggests that the injector is not working properly.

5.4: Combining OBD2 Data with Multimeter Testing

The most effective approach to diagnosing fuel injector resistance issues is to combine the information from an OBD2 scanner with a multimeter test.

First, use the OBD2 scanner to retrieve any DTCs related to fuel injectors. Then, use a multimeter to measure the resistance of the injectors. By comparing the OBD2 data with the multimeter readings, you can gain a comprehensive understanding of the injector’s condition.

For example, if the OBD2 scanner shows a code for “Injector Circuit Low” and the multimeter reads a resistance value below the specified range, it confirms that the injector has a short circuit and needs to be replaced.

- DTC Retrieval: Read and interpret diagnostic trouble codes related to fuel injectors.

- Live Data: Monitor fuel injector pulse width in real-time.

- Injector Testing: Activate or deactivate injectors to observe engine response.

- Combined Approach: Use OBD2 data in conjunction with multimeter testing for accurate diagnosis.

Alt Text: An OBD2 scanner connected to a Honda vehicle, displaying diagnostic trouble codes related to fuel injectors.

6: What Tools are Needed to Check Fuel Injector Resistance?

Checking fuel injector resistance requires a few basic tools, primarily a digital multimeter and some safety equipment. Having the right tools ensures accurate measurements and a safe working environment.

6.1: Digital Multimeter

A digital multimeter is the most essential tool for checking fuel injector resistance. It allows you to measure the resistance in ohms (Ω) accurately. Look for a multimeter that offers:

- Accuracy: A high degree of accuracy to ensure reliable readings.

- Auto-Ranging: Automatically selects the appropriate resistance range.

- Continuity Test: An audible continuity test to check for open circuits.

- Digital Display: A clear and easy-to-read digital display.

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can recommend suitable multimeters for automotive diagnostics.

6.2: Safety Glasses

Safety glasses are crucial to protect your eyes from fuel splashes or debris while working on the fuel system. Always wear safety glasses when disconnecting fuel lines or handling fuel injectors.

6.3: Gloves

Wearing gloves is recommended to protect your skin from fuel and other chemicals. Nitrile gloves are a good choice as they are resistant to most automotive fluids.

6.4: Rags

Have plenty of clean rags on hand to wipe up any spilled fuel. Fuel spills can be a fire hazard and should be cleaned up immediately.

6.5: OBD2 Scanner (Optional)

While not strictly necessary for measuring resistance, an OBD2 scanner can provide valuable information about the fuel injection system and help diagnose resistance-related issues. A scanner can retrieve DTCs and provide live data.

6.6: Vehicle Service Manual

A vehicle service manual is an invaluable resource for locating fuel injectors, understanding the fuel system layout, and finding the specified resistance range for your vehicle. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can provide access to service information for many Honda models.

- Multimeter: Essential for measuring resistance in ohms.

- Safety Glasses: Protect your eyes from fuel splashes.

- Gloves: Protect your skin from fuel and chemicals.

- Rags: Clean up fuel spills immediately.

- OBD2 Scanner: Optional for retrieving DTCs and live data.

- Service Manual: Provides valuable information about the fuel system.

7: Step-by-Step Guide to Checking Honda OBD2 Fuel Injector Resistance

Checking Honda OBD2 fuel injector resistance is a straightforward process that can be accomplished with a few basic tools and some patience. Follow these steps for accurate and safe measurements:

7.1: Safety Precautions

- Work in a Well-Ventilated Area: Fuel vapors are flammable and can be harmful if inhaled.

- Disconnect the Battery: Disconnect the negative battery cable to prevent accidental electrical sparks.

- Wear Safety Glasses and Gloves: Protect your eyes and skin from fuel splashes.

- No Smoking: Do not smoke or have any open flames near the fuel system.

- Have a Fire Extinguisher Nearby: Keep a fire extinguisher readily available in case of a fuel fire.

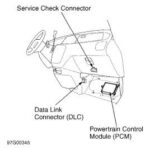

7.2: Locate the Fuel Injectors

Refer to your vehicle’s service manual to locate the fuel injectors. They are typically located on the intake manifold, near the engine cylinders.

7.3: Disconnect the Electrical Connectors

- Gently remove the electrical connector from each fuel injector.

- Inspect the connectors for any signs of corrosion or damage. Clean or replace as necessary.

7.4: Set Up the Multimeter

- Set your digital multimeter to measure resistance (ohms Ω).

- If your multimeter has auto-ranging, select the auto-ranging function. Otherwise, select a resistance range that is appropriate for the expected resistance of the injectors (e.g., 200 ohms).

7.5: Measure the Resistance

- Place the multimeter probes on the two terminals of the fuel injector.

- Note the resistance reading displayed on the multimeter.

- Repeat this process for each fuel injector.

7.6: Compare the Readings

- Compare the resistance reading for each injector to the specified resistance range for your vehicle.

- Refer to your vehicle’s service manual or a reliable source like MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for the correct specifications.

7.7: Interpret the Results

- Within Range: If the resistance reading falls within the specified range, the injector is likely functioning correctly from an electrical standpoint.

- Too High: If the resistance reading is significantly higher than the specified range, it indicates a potential open circuit or high resistance within the injector coil.

- Too Low: If the resistance reading is significantly lower than the specified range, it indicates a potential short circuit within the injector coil.

- Zero or Infinite: A reading of zero ohms indicates a short circuit, while an infinite reading indicates an open circuit.

7.8: Take Corrective Action

Based on the resistance readings, take the appropriate corrective action:

-

Injectors Within Range: If all injectors are within the specified range, the resistance is likely not the cause of any engine problems. Investigate other potential issues, such as clogged injectors or vacuum leaks.

-

Faulty Injector: If one or more injectors have resistance readings outside the specified range, replace the faulty injectors with new ones.

-

Safety First: Disconnect the battery and work in a well-ventilated area.

-

Locate Injectors: Refer to the service manual to find the fuel injectors.

-

Disconnect Connectors: Remove the electrical connectors from each injector.

-

Set Multimeter: Set the multimeter to measure resistance (ohms Ω).

-

Measure Resistance: Place probes on the injector terminals and record the reading.

-

Compare Readings: Compare the readings to the specified range for your vehicle.

-

Take Action: Replace any faulty injectors with resistance readings outside the specified range.

8: What Causes Fuel Injector Resistance to Change Over Time?

Fuel injector resistance can change over time due to several factors, primarily related to the harsh operating environment within the engine. Understanding these causes can help you prevent premature injector failure and maintain optimal engine performance.

8.1: Heat

Fuel injectors are subjected to high temperatures from the engine. Prolonged exposure to heat can degrade the insulation on the injector coil windings, leading to increased resistance.

According to a study by the National Renewable Energy Laboratory (NREL), high temperatures can accelerate the degradation of electrical components in automotive systems.

8.2: Vibration

The constant vibration of the engine can cause mechanical stress on the injector components, including the coil windings and electrical connections. This stress can lead to increased resistance or even open circuits.

8.3: Contamination

Fuel injectors are exposed to fuel contaminants, such as dirt, rust, and debris. These contaminants can clog the injector nozzles and also corrode the electrical connections, leading to increased resistance.

Using high-quality fuel and regularly replacing the fuel filter can help prevent fuel contamination.

8.4: Corrosion

Corrosion can occur on the injector terminals and electrical connections due to exposure to moisture and road salt. Corrosion increases resistance and can eventually lead to a complete loss of electrical contact.

Protecting the electrical connections with dielectric grease can help prevent corrosion.

8.5: Wear and Tear

Over time, the mechanical components of the fuel injector can wear out, affecting the injector’s performance and resistance. The injector needle, spring, and solenoid can all be subject to wear and tear.

Regular fuel injector cleaning and maintenance can help extend the life of the injectors.

8.6: Electrical Stress

Electrical stress, such as voltage spikes or surges, can damage the injector coil windings and lead to increased resistance.

Ensuring a stable and reliable electrical system can help prevent electrical stress on the fuel injectors.

- Heat: Degrades insulation on coil windings, increasing resistance.

- Vibration: Causes mechanical stress on injector components.

- Contamination: Clogs nozzles and corrodes electrical connections.

- Corrosion: Increases resistance on terminals and connections.

- Wear and Tear: Affects mechanical components like needles and springs.

- Electrical Stress: Damages coil windings, increasing resistance.

9: Can You Clean Fuel Injectors to Restore Proper Resistance?

While cleaning fuel injectors can improve their performance, it typically does not restore proper resistance if the resistance has changed due to electrical damage. Cleaning primarily addresses issues related to clogged nozzles and deposits.

9.1: Cleaning Methods

There are several methods for cleaning fuel injectors:

- Fuel Additives: Fuel additives containing detergents can help clean injectors while driving.

- Professional Cleaning: Professional fuel injector cleaning services use specialized equipment to clean injectors off the vehicle. This typically involves ultrasonic cleaning and back-flushing.

- DIY Cleaning: DIY cleaning involves removing the injectors and cleaning them with carburetor cleaner or a similar solvent.

9.2: Impact on Resistance

Cleaning primarily addresses issues related to clogged nozzles and deposits that affect fuel flow. It does not typically repair electrical damage or restore degraded insulation on the injector coil windings.

If the fuel injector resistance is outside the specified range due to electrical damage, cleaning will not fix the problem. The injector will need to be replaced.

9.3: When Cleaning is Beneficial

Cleaning can be beneficial in the following situations:

- Clogged Injectors: Cleaning can remove deposits that are clogging the injector nozzles and affecting fuel flow.

- Poor Spray Pattern: Cleaning can restore a proper spray pattern, improving combustion efficiency.

- Rough Idling: Cleaning can help smooth out a rough idle caused by inconsistent fuel delivery.

However, if the resistance is the issue, cleaning will not resolve it.

- Cleaning Addresses Flow: Primarily focuses on removing deposits and restoring fuel flow.

- No Impact on Electrical Damage: Does not repair electrical damage or restore insulation.

- Replace if Resistance is Off: Injector needs replacement if resistance is outside the range.

- Beneficial for Clogs: Helpful for addressing clogged nozzles and poor spray patterns.

10: What are the Consequences of Ignoring Incorrect Fuel Injector Resistance?

Ignoring incorrect fuel injector resistance can lead to a cascade of problems, affecting engine performance, fuel economy, emissions, and overall reliability. Addressing resistance issues promptly can prevent more serious and costly repairs down the road.

10.1: Reduced Engine Performance

Incorrect fuel delivery due to resistance problems can significantly reduce engine performance. The engine may hesitate during acceleration, lack power, and run roughly.

In severe cases, the engine may not be able to produce enough power to move the vehicle.

10.2: Poor Fuel Economy

Over-fueling or under-fueling due to resistance problems can significantly impact fuel economy. You may notice a decrease in miles per gallon (MPG) and increased fuel consumption.

10.3: Increased Emissions

Inefficient combustion due to incorrect fuel delivery increases the levels of harmful pollutants, such as hydrocarbons (HC), carbon monoxide (CO), and nitrogen oxides (NOx). This can cause the vehicle to fail an emissions test and contribute to air pollution.

10.4: Damage to Other Components

Prolonged operation with faulty fuel injectors can damage other engine components. Over-fueling can wash oil off cylinder walls, leading to increased wear and tear on piston rings and cylinder bores. Misfires can damage the catalytic converter.

10.5: Engine Failure

In extreme cases, ignoring incorrect fuel injector resistance can lead to engine failure. Over-fueling can cause гидроlock (hydraulic lock) of the engine, while under-fueling can cause excessive heat and damage to valves and pistons.

10.6: Safety Hazards

Fuel leaks due to damaged fuel injectors can create a fire risk. Fuel leaks should be addressed immediately to prevent potential safety hazards.

- Performance Loss: Reduced power, hesitation, and rough running.

- Poor Economy: Decreased miles per gallon and increased fuel consumption.

- High Emissions: Increased levels of harmful pollutants.

- Component Damage: Damage to catalytic converter, piston rings, and cylinder bores.

- Engine Failure: Potential for гидроlock or severe engine damage.

- Safety Risk: Fuel leaks create a fire hazard.

FAQ: Honda OBD2 Fuel Injector Resistance

1. What is the typical resistance range for Honda OBD2 fuel injectors?

The typical resistance range for Honda OBD2 fuel injectors is between 10-13 ohms for high-impedance injectors and 2-4 ohms for low-impedance injectors.

2. How do I check fuel injector resistance on my Honda?

You can check fuel injector resistance using a digital multimeter. Disconnect the injector, set the multimeter to ohms, and measure the resistance across the injector terminals.

3. What does it mean if my fuel injector resistance is too high?

If your fuel injector resistance is too high, it indicates a potential open circuit or high resistance within the injector coil. The injector may not open properly.

4. What does it mean if my fuel injector resistance is too low?

If your fuel injector resistance is too low, it indicates a potential short circuit within the injector coil. The injector may stay open too long or overheat.

5. Can I use an OBD2 scanner to check fuel injector resistance?

While an OBD2 scanner cannot directly measure fuel injector resistance, it can provide valuable information about injector performance and help diagnose resistance-related issues.

6. Will cleaning my fuel injectors restore proper resistance?

Cleaning fuel injectors primarily addresses issues related to clogged nozzles and deposits. It does not typically restore proper resistance if the resistance has changed due to electrical damage.

7. What are the symptoms of incorrect fuel injector resistance?

Symptoms of incorrect fuel injector resistance include a check engine light, poor fuel economy, rough idling, misfires, and hesitation during acceleration.

8. What causes fuel injector resistance to change over time?

Fuel injector resistance can change over time due to heat, vibration, contamination, corrosion, wear and tear, and electrical stress.

9. Is it safe to drive with incorrect fuel injector resistance?

It is not recommended to drive with incorrect fuel injector resistance. It can lead to reduced engine performance, poor fuel economy, increased emissions, and damage to other components.

10. How often should I check my fuel injector resistance?

You should check your fuel injector resistance if you are experiencing any symptoms of fuel injection problems or as part of a regular maintenance schedule, typically every 80,000 to 100,000 miles.Maintaining your Honda’s fuel injectors is essential for optimal performance and longevity. If you’re experiencing any of the symptoms mentioned above, don’t hesitate to contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert advice and assistance.

For further assistance with your Honda’s fuel injection system, contact us today:

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- Whatsapp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Let MERCEDES-DIAGNOSTIC-TOOL.EDU.VN help you keep your Honda running smoothly and efficiently!