Is My Truck Obd2 compliant? Determine your truck’s OBD2 compliance with this comprehensive guide, brought to you by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, to properly diagnose and maintain your vehicle. We will help you navigate the complexities of OBD2 compliance, find the right tools, and understand your truck’s diagnostic system, while also exploring advanced diagnostics and hidden features for Mercedes-Benz trucks, ultimately enhancing your vehicle’s performance and longevity using specialized scan tools and coding techniques. This article also touches on advanced diagnostics, scan tool compatibility, and Mercedes-Benz specific features.

Contents

- 1. Understanding OBD2 Compliance for Trucks

- 2. Why OBD2 Compliance Matters for Truck Owners

- 3. How to Check if Your Truck Is OBD2 Compliant

- 4. Understanding the OBD2 Port in Your Truck

- 5. Essential Tools for OBD2 Truck Diagnostics

- 6. Using an OBD2 Scanner on Your Truck: A Step-by-Step Guide

- 7. Interpreting OBD2 Codes: A Comprehensive Guide

- 8. Common OBD2 Codes and Their Meanings for Trucks

- 9. Advanced Diagnostics: Going Beyond Basic OBD2 Scanning

- 10. OBD2 Scan Tools vs. Professional Diagnostic Equipment

- 11. Choosing the Right OBD2 Scanner for Your Truck

- 12. Maintaining Your Truck’s OBD2 System: Tips and Best Practices

- 13. When to Seek Professional Help for OBD2 Issues

- 14. The Future of OBD2 and Truck Diagnostics

- 15. Introduction to Mercedes-Benz Truck Diagnostics

- 16. Why Mercedes-Benz Truck Diagnostics Differs from Standard OBD2

- 17. Essential Diagnostic Tools for Mercedes-Benz Trucks

- 18. Step-by-Step: Diagnosing a Mercedes-Benz Truck with XENTRY/DAS

- 19. Common Issues and Codes Specific to Mercedes-Benz Trucks

- 20. Advanced Coding and Programming for Mercedes-Benz Trucks

- 21. Unlocking Hidden Features: Customizing Your Mercedes-Benz Truck

- 22. The Risks and Rewards of DIY Mercedes-Benz Truck Diagnostics

- 23. Partnering with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Your Diagnostic Needs

- 24. Success Stories: How OBD2 Diagnostics Saved the Day

- 25. Getting Started with OBD2 Diagnostics: A Quick Checklist

- 26. FAQ: Addressing Common Questions About Truck OBD2 Systems

- 27. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Expert Assistance

1. Understanding OBD2 Compliance for Trucks

Is my truck OBD2 compliant? To determine this, understanding the OBD2 standard, especially in relation to trucks, is essential. OBD2, or On-Board Diagnostics version 2, is a standardized system that provides access to a wealth of information about a vehicle’s health. This standard was made mandatory in the United States for all cars and light trucks manufactured after 1996. According to the EPA (Environmental Protection Agency), OBD2 systems monitor the performance of major engine components, including those responsible for controlling emissions. This regulation ensures that vehicles meet specific emissions standards, contributing to cleaner air and environmental protection. Therefore, if your truck was manufactured in 1996 or later and sold in the United States, it is most likely OBD2 compliant. The system is designed to detect malfunctions, store diagnostic trouble codes (DTCs), and alert the driver via the “check engine” light on the dashboard, ensuring timely intervention and maintenance.

2. Why OBD2 Compliance Matters for Truck Owners

Why is OBD2 compliance important for truck owners? OBD2 compliance offers several benefits for truck owners. First and foremost, it facilitates accurate and efficient diagnostics. When the “check engine” light comes on, an OBD2 scanner can quickly read the diagnostic trouble codes, pinpointing the source of the problem. This capability is invaluable for both professional mechanics and DIY enthusiasts, saving time and money on repairs. Secondly, OBD2 compliance ensures that your truck meets environmental standards. Regular monitoring of emission-related components helps prevent excessive pollution, contributing to cleaner air and compliance with local and federal regulations. Furthermore, OBD2 data can provide insights into your truck’s overall performance and fuel efficiency, allowing you to optimize driving habits and maintenance schedules for improved economy and longevity. Therefore, OBD2 compliance is not just a regulatory requirement but also a valuable tool for maintaining your truck’s health, performance, and environmental responsibility.

3. How to Check if Your Truck Is OBD2 Compliant

How can you check if your truck is OBD2 compliant? To verify OBD2 compliance, start by checking the vehicle’s manufacturing year. If your truck was made in 1996 or later for the US market, it is likely OBD2 compliant. Next, locate the OBD2 port, which is typically found under the dashboard on the driver’s side. The port is a 16-pin connector, and its presence is a good indicator of OBD2 compliance. However, the most definitive method is to check for an “OBD2 compliant” label under the hood. This label, often found on the Vehicle Emission Control Information (VECI) sticker, confirms that the vehicle meets OBD2 standards. If you are still unsure, consult your truck’s owner’s manual or contact the manufacturer with your Vehicle Identification Number (VIN) to confirm OBD2 compliance. This thorough approach ensures you have accurate information about your truck’s diagnostic capabilities.

4. Understanding the OBD2 Port in Your Truck

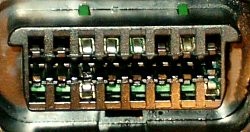

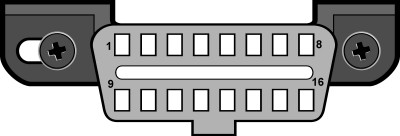

What is the OBD2 port and where is it located in your truck? The OBD2 port, also known as the Diagnostic Link Connector (DLC), is a standardized 16-pin connector used to access your truck’s diagnostic data. According to SAE International, this port is designed to provide a standardized interface for accessing a vehicle’s computer. In most trucks, the OBD2 port is located under the dashboard on the driver’s side. It is usually easily accessible without tools, although its exact placement can vary depending on the make and model of your truck. Once you locate the port, you can plug in an OBD2 scanner to read diagnostic trouble codes, monitor vehicle parameters, and perform various diagnostic tests. Understanding the OBD2 port and its location is the first step in leveraging the diagnostic capabilities of your truck.

OBD2 Port Location

OBD2 Port Location

5. Essential Tools for OBD2 Truck Diagnostics

What are the essential tools for OBD2 truck diagnostics? Several tools can help you diagnose your OBD2-compliant truck effectively. The most basic is an OBD2 scanner, which reads diagnostic trouble codes (DTCs) and displays them for interpretation. A more advanced tool is a scan tool, which offers enhanced capabilities such as live data streaming, component testing, and bidirectional control. For Mercedes-Benz trucks, specialized scan tools like the Mercedes-Benz Star Diagnosis system or Autel MaxiSys provide in-depth diagnostics and access to proprietary systems. Additionally, having a multimeter, a set of basic hand tools, and a comprehensive repair manual can aid in troubleshooting and performing necessary repairs. Choosing the right tools depends on your diagnostic needs and technical expertise, ensuring you can accurately diagnose and address issues with your truck.

6. Using an OBD2 Scanner on Your Truck: A Step-by-Step Guide

How do you use an OBD2 scanner on your truck? Here is a step-by-step guide on how to use an OBD2 scanner on your truck:

- Locate the OBD2 Port: Find the 16-pin OBD2 port, typically located under the dashboard on the driver’s side.

- Plug in the Scanner: With the ignition off, plug the OBD2 scanner into the port.

- Turn on the Ignition: Turn the ignition to the “on” position without starting the engine.

- Power on the Scanner: The scanner should power on automatically. If not, ensure it has batteries or is properly connected.

- Read Diagnostic Trouble Codes (DTCs): Follow the scanner’s instructions to read DTCs. This usually involves selecting a “Read Codes” or “Diagnostic” option.

- Interpret the Codes: Write down the codes and consult a repair manual or online database to understand their meaning.

- Clear the Codes (Optional): If desired, use the scanner to clear the codes after addressing the issue. Note that clearing codes without fixing the problem will only result in their reappearance.

- Turn off the Ignition and Remove the Scanner: Once finished, turn off the ignition and remove the OBD2 scanner from the port.

This process allows you to retrieve valuable diagnostic information from your truck’s computer, aiding in accurate troubleshooting and repairs.

7. Interpreting OBD2 Codes: A Comprehensive Guide

How do you interpret OBD2 codes effectively? Interpreting OBD2 codes involves understanding the structure and meaning of the diagnostic trouble codes (DTCs) retrieved from your truck’s computer. According to the Society of Automotive Engineers (SAE), OBD2 codes are five-character alphanumeric codes. The first character indicates the system: P for Powertrain, B for Body, C for Chassis, and U for Network. The second character denotes whether the code is generic (0) or manufacturer-specific (1). The third character specifies the subsystem, such as fuel system, ignition system, or emission control. The last two characters are specific fault codes that pinpoint the exact problem. For example, a code like P0300 indicates a random/multiple cylinder misfire in the powertrain system. To effectively interpret OBD2 codes, consult a reliable repair manual, online database, or professional diagnostic tool that provides detailed descriptions and potential causes for each code. This knowledge enables you to accurately diagnose and address issues with your truck, ensuring efficient and effective repairs.

8. Common OBD2 Codes and Their Meanings for Trucks

What are the common OBD2 codes for trucks and what do they mean? Several common OBD2 codes frequently appear in trucks, each indicating specific issues. Here are a few examples:

- P0300: Random/Multiple Cylinder Misfire. This code suggests that one or more cylinders are not firing properly, leading to rough running and potential engine damage.

- P0171/P0174: System Too Lean (Bank 1/Bank 2). These codes indicate that the engine is receiving too much air or not enough fuel, potentially caused by vacuum leaks, faulty sensors, or fuel delivery problems.

- P0420: Catalyst System Efficiency Below Threshold (Bank 1). This code suggests that the catalytic converter is not functioning efficiently, leading to increased emissions.

- P0401: Exhaust Gas Recirculation (EGR) Flow Insufficient Detected. This code indicates a problem with the EGR system, which helps reduce emissions by recirculating exhaust gases back into the engine.

- P0101: Mass Air Flow (MAF) Sensor Circuit Range/Performance Problem. This code suggests an issue with the MAF sensor, which measures the amount of air entering the engine.

Understanding these common OBD2 codes and their potential causes can help you quickly diagnose and address issues with your truck, ensuring optimal performance and longevity.

9. Advanced Diagnostics: Going Beyond Basic OBD2 Scanning

How can you perform advanced diagnostics beyond basic OBD2 scanning? Advanced diagnostics go beyond simply reading OBD2 codes and involve in-depth analysis and testing to pinpoint complex issues. This often requires specialized scan tools that offer bidirectional control, allowing you to command components on and off to test their functionality. Live data streaming is another crucial feature, enabling you to monitor various engine parameters in real-time to identify anomalies. Additionally, advanced diagnostics may involve performing compression tests, fuel pressure tests, and electrical circuit testing to assess the health of individual components. For Mercedes-Benz trucks, advanced diagnostics may require the use of proprietary software like XENTRY or DAS (Diagnostic Assistance System), which provide access to detailed diagnostic routines and coding functions. By combining advanced scan tools, technical knowledge, and methodical testing, you can effectively diagnose and resolve complex issues with your truck.

10. OBD2 Scan Tools vs. Professional Diagnostic Equipment

What is the difference between OBD2 scan tools and professional diagnostic equipment? OBD2 scan tools and professional diagnostic equipment serve different purposes and offer varying levels of functionality. OBD2 scan tools are typically basic devices designed to read and clear diagnostic trouble codes (DTCs) from the vehicle’s computer. They are relatively inexpensive and easy to use, making them suitable for DIY enthusiasts and general troubleshooting. Professional diagnostic equipment, on the other hand, offers advanced capabilities such as bidirectional control, live data streaming, component testing, and access to proprietary systems. These tools are used by professional mechanics and technicians for in-depth diagnostics and repairs. For Mercedes-Benz trucks, professional diagnostic equipment like the Mercedes-Benz Star Diagnosis system provides access to detailed diagnostic routines, coding functions, and software updates. While OBD2 scan tools can help identify basic issues, professional diagnostic equipment is necessary for comprehensive diagnostics and repairs.

11. Choosing the Right OBD2 Scanner for Your Truck

How do you choose the right OBD2 scanner for your truck? Selecting the right OBD2 scanner depends on your diagnostic needs, technical expertise, and budget. Basic OBD2 scanners are suitable for reading and clearing diagnostic trouble codes (DTCs), making them ideal for simple troubleshooting. Mid-range scanners offer additional features such as live data streaming, freeze frame data, and enhanced code definitions, providing more in-depth diagnostic information. For advanced diagnostics, consider a professional-grade scan tool with bidirectional control, component testing, and access to proprietary systems. For Mercedes-Benz trucks, specialized scan tools like the Autel MaxiSys or iCarsoft MB II offer enhanced compatibility and access to Mercedes-specific diagnostic routines. When choosing an OBD2 scanner, consider factors such as compatibility with your truck’s make and model, ease of use, features, and customer reviews. This ensures you select a scanner that meets your diagnostic needs and provides accurate and reliable results.

12. Maintaining Your Truck’s OBD2 System: Tips and Best Practices

How can you maintain your truck’s OBD2 system effectively? Maintaining your truck’s OBD2 system involves several best practices to ensure accurate diagnostics and optimal performance. First, regularly inspect the OBD2 port for damage or corrosion, as a faulty port can prevent proper communication with the scanner. When using an OBD2 scanner, ensure it is compatible with your truck’s make and model to avoid misreadings or system errors. Keep your truck’s battery in good condition, as a weak battery can cause false DTCs. Regularly check and replace faulty sensors, as these can trigger incorrect codes and affect engine performance. Additionally, follow your truck’s recommended maintenance schedule, including oil changes, spark plug replacements, and air filter replacements, to prevent issues that can trigger OBD2 codes. By following these tips and best practices, you can maintain your truck’s OBD2 system and ensure accurate and reliable diagnostics.

13. When to Seek Professional Help for OBD2 Issues

When should you seek professional help for OBD2 issues with your truck? While basic OBD2 diagnostics can be performed by DIY enthusiasts, certain situations warrant seeking professional help. If you are unfamiliar with OBD2 codes or lack the technical expertise to interpret them accurately, consulting a professional mechanic is advisable. Complex issues that require advanced diagnostics, such as those involving the engine, transmission, or ABS system, should be handled by experienced technicians with specialized tools and knowledge. If you have attempted to repair an issue based on OBD2 codes but the problem persists or worsens, seeking professional help is recommended. Additionally, if your truck exhibits symptoms such as severe engine misfires, loss of power, or unusual noises, it is best to consult a professional mechanic for a thorough diagnosis and repair. Knowing when to seek professional help ensures that your truck receives the appropriate care and attention, preventing further damage and ensuring your safety.

14. The Future of OBD2 and Truck Diagnostics

What does the future hold for OBD2 and truck diagnostics? The future of OBD2 and truck diagnostics is evolving rapidly, driven by advancements in technology and increasing demand for more comprehensive and accurate diagnostic capabilities. Enhanced OBD2 systems, such as OBD3, are being developed to provide real-time monitoring of vehicle emissions and performance, with the ability to automatically report issues to regulatory agencies. Wireless OBD2 adapters and smartphone apps are becoming increasingly popular, offering convenient access to diagnostic data and vehicle information. Predictive diagnostics, which use data analytics and machine learning to anticipate potential issues before they occur, are also gaining traction. For Mercedes-Benz trucks, future diagnostic systems are expected to integrate more closely with the vehicle’s electronic control units (ECUs), providing deeper insights into vehicle performance and enabling over-the-air software updates. These advancements promise to revolutionize truck diagnostics, making it more efficient, accurate, and accessible.

15. Introduction to Mercedes-Benz Truck Diagnostics

What are the key aspects of Mercedes-Benz truck diagnostics? Mercedes-Benz truck diagnostics involves specialized procedures and tools due to the complex electronic systems in these vehicles. Key aspects include using diagnostic software like XENTRY or DAS (Diagnostic Assistance System), which provides access to detailed diagnostic routines, coding functions, and software updates. Understanding Mercedes-Benz-specific diagnostic trouble codes (DTCs) and their meanings is crucial for accurate troubleshooting. Live data streaming allows technicians to monitor various engine parameters in real-time, identifying anomalies and potential issues. Additionally, component testing, which involves activating and deactivating components to assess their functionality, is essential for diagnosing complex problems. Proper training and experience are necessary to effectively diagnose and repair Mercedes-Benz trucks, ensuring optimal performance and longevity.

16. Why Mercedes-Benz Truck Diagnostics Differs from Standard OBD2

How does Mercedes-Benz truck diagnostics differ from standard OBD2 diagnostics? Mercedes-Benz truck diagnostics differs significantly from standard OBD2 diagnostics due to the advanced and proprietary electronic systems used in these vehicles. While standard OBD2 provides generic diagnostic trouble codes (DTCs) related to emissions, Mercedes-Benz diagnostics requires specialized software like XENTRY or DAS (Diagnostic Assistance System) to access detailed diagnostic routines and coding functions. These systems provide access to a wider range of DTCs, including those related to the engine, transmission, ABS, and other vehicle systems. Live data streaming in Mercedes-Benz diagnostics offers more parameters and greater precision than standard OBD2. Furthermore, Mercedes-Benz diagnostics allows for component testing and bidirectional control, enabling technicians to activate and deactivate components to assess their functionality. This level of detail and control is not available in standard OBD2, making Mercedes-Benz truck diagnostics a more complex and specialized process.

17. Essential Diagnostic Tools for Mercedes-Benz Trucks

What are the essential diagnostic tools for working on Mercedes-Benz trucks? Several essential diagnostic tools are necessary for effectively working on Mercedes-Benz trucks. The most crucial tool is the Mercedes-Benz Star Diagnosis system, which includes XENTRY or DAS (Diagnostic Assistance System) software. This system provides access to detailed diagnostic routines, coding functions, and software updates specific to Mercedes-Benz vehicles. A professional-grade scan tool with bidirectional control and live data streaming capabilities is also essential. Additionally, a multimeter, oscilloscope, and specialized Mercedes-Benz tools like the engine compression tester and fuel pressure tester are necessary for thorough diagnostics. Having access to Mercedes-Benz-specific repair manuals and wiring diagrams is also crucial for accurate troubleshooting and repairs. These tools, combined with proper training and experience, enable technicians to effectively diagnose and repair Mercedes-Benz trucks.

18. Step-by-Step: Diagnosing a Mercedes-Benz Truck with XENTRY/DAS

How can you diagnose a Mercedes-Benz truck using XENTRY/DAS software? Here is a step-by-step guide on diagnosing a Mercedes-Benz truck using XENTRY/DAS software:

- Connect the Diagnostic Interface: Connect the Mercedes-Benz diagnostic interface to the truck’s OBD2 port and the computer running XENTRY/DAS software.

- Launch XENTRY/DAS Software: Open the XENTRY/DAS software and select the appropriate vehicle model and year.

- Perform a Quick Test: Run a quick test to scan all electronic control units (ECUs) for diagnostic trouble codes (DTCs).

- Review Diagnostic Trouble Codes: Review the DTCs and their descriptions, noting any relevant information.

- Perform Guided Diagnostics: Follow the guided diagnostics routines provided by XENTRY/DAS to further investigate the issue. This may involve performing component tests, measuring values, and checking wiring.

- Interpret Results and Take Action: Interpret the results of the diagnostic tests and take appropriate action, such as replacing faulty components, repairing wiring, or performing software updates.

- Clear Diagnostic Trouble Codes: After addressing the issue, clear the DTCs and perform another quick test to ensure the problem has been resolved.

- Verify Repair: Verify the repair by test-driving the truck and monitoring its performance.

This process allows you to leverage the advanced diagnostic capabilities of XENTRY/DAS software to effectively diagnose and repair Mercedes-Benz trucks.

19. Common Issues and Codes Specific to Mercedes-Benz Trucks

What are the common issues and diagnostic codes specific to Mercedes-Benz trucks? Mercedes-Benz trucks often exhibit specific issues and diagnostic codes due to their advanced electronic systems. Common issues include problems with the AdBlue system (SCR system), which can trigger codes related to NOx emissions. Faulty sensors, such as the mass air flow (MAF) sensor, oxygen sensor, and crankshaft position sensor, can also trigger specific codes. Issues with the electronic control units (ECUs), such as the engine control unit (ECU) and transmission control unit (TCU), are also common. Specific diagnostic codes may include those related to the engine, transmission, ABS, and other vehicle systems. Understanding these common issues and diagnostic codes can help technicians quickly diagnose and address problems with Mercedes-Benz trucks, ensuring optimal performance and longevity.

20. Advanced Coding and Programming for Mercedes-Benz Trucks

What does advanced coding and programming for Mercedes-Benz trucks entail? Advanced coding and programming for Mercedes-Benz trucks involves modifying the software parameters of the vehicle’s electronic control units (ECUs) to customize features, improve performance, or address specific issues. This may include coding new components, such as replacement ECUs or sensors, to ensure they function correctly with the vehicle’s systems. Programming can also involve updating the software in the ECUs to the latest version, which may include bug fixes, performance improvements, and new features. Additionally, advanced coding can be used to enable or disable certain features, such as speed limiters, daytime running lights, or specific driving modes. Performing advanced coding and programming requires specialized software like XENTRY/DAS and a thorough understanding of the vehicle’s electronic systems.

21. Unlocking Hidden Features: Customizing Your Mercedes-Benz Truck

How can you unlock hidden features and customize your Mercedes-Benz truck? Unlocking hidden features on your Mercedes-Benz truck can enhance its functionality and personalize your driving experience. According to Mercedes-Benz forums, certain features, such as enhanced display options, ambient lighting customization, and performance settings, may be hidden or disabled by default. Unlocking these features typically requires advanced coding using specialized software like XENTRY/DAS. The process involves accessing the vehicle’s electronic control units (ECUs) and modifying specific parameters to enable the desired features. Before attempting to unlock hidden features, research the compatibility of the modifications with your truck’s make and model. Therefore, ensure you have a thorough understanding of the coding process to avoid causing unintended issues.

22. The Risks and Rewards of DIY Mercedes-Benz Truck Diagnostics

What are the risks and rewards of performing DIY Mercedes-Benz truck diagnostics? Performing DIY Mercedes-Benz truck diagnostics offers both potential rewards and inherent risks. The rewards include saving money on labor costs, gaining a deeper understanding of your truck’s systems, and the satisfaction of resolving issues yourself. However, the risks include misdiagnosing problems, causing further damage to the vehicle, and potentially voiding the warranty. Mercedes-Benz trucks have complex electronic systems that require specialized knowledge and tools to diagnose accurately. Using incorrect diagnostic procedures or tools can lead to incorrect readings, improper repairs, and potential safety hazards. Therefore, before attempting DIY diagnostics, assess your technical skills, research the specific issue thoroughly, and invest in the appropriate diagnostic tools. If you are unsure about any aspect of the diagnostic process, seeking professional help is always the safest option.

23. Partnering with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Your Diagnostic Needs

How can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN assist with your Mercedes-Benz truck diagnostic needs? MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a range of services and expertise to assist with your Mercedes-Benz truck diagnostic needs. We provide access to high-quality diagnostic tools, including Mercedes-Benz Star Diagnosis systems and professional-grade scan tools, ensuring accurate and reliable diagnostics. Our team of experienced technicians offers remote diagnostic support, guiding you through the diagnostic process and helping you interpret diagnostic trouble codes. We also provide training and resources to enhance your diagnostic skills and knowledge. Whether you are a DIY enthusiast or a professional mechanic, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is your trusted partner for all your Mercedes-Benz truck diagnostic needs.

24. Success Stories: How OBD2 Diagnostics Saved the Day

Can you provide examples of how OBD2 diagnostics have successfully resolved truck issues? Numerous success stories illustrate the effectiveness of OBD2 diagnostics in resolving truck issues. In one case, a truck owner experienced a sudden loss of power and a flashing “check engine” light. Using an OBD2 scanner, they retrieved a P0300 code, indicating a random/multiple cylinder misfire. Further investigation revealed a faulty ignition coil, which was replaced, resolving the misfire and restoring the truck’s performance. In another case, a truck exhibited poor fuel economy and a P0171 code, indicating a lean condition. Using live data streaming, a technician identified a vacuum leak in the intake manifold, which was repaired, improving fuel economy and eliminating the code. These success stories demonstrate the power of OBD2 diagnostics in accurately identifying and resolving truck issues, saving time and money on repairs.

25. Getting Started with OBD2 Diagnostics: A Quick Checklist

What is a quick checklist for getting started with OBD2 diagnostics? Here is a quick checklist to help you get started with OBD2 diagnostics:

- Verify OBD2 Compliance: Confirm that your truck is OBD2 compliant by checking the manufacturing year and looking for the OBD2 port.

- Gather Essential Tools: Acquire an OBD2 scanner, repair manual, and basic hand tools.

- Locate the OBD2 Port: Find the 16-pin OBD2 port, typically located under the dashboard on the driver’s side.

- Read Diagnostic Trouble Codes: Plug in the scanner, turn on the ignition, and read the diagnostic trouble codes (DTCs).

- Interpret the Codes: Consult a repair manual or online database to understand the meaning of the codes.

- Take Action: Address the issue by repairing or replacing faulty components.

- Clear the Codes (Optional): Clear the codes after addressing the issue.

- Verify Repair: Test-drive the truck to ensure the problem has been resolved.

Following this checklist will help you effectively diagnose and address issues with your truck, ensuring optimal performance and longevity.

26. FAQ: Addressing Common Questions About Truck OBD2 Systems

Here are some frequently asked questions (FAQ) about truck OBD2 systems:

- Q: What does OBD2 stand for?

- A: OBD2 stands for On-Board Diagnostics version 2, a standardized system for monitoring vehicle emissions and performance.

- Q: Where is the OBD2 port located in my truck?

- A: The OBD2 port is typically located under the dashboard on the driver’s side.

- Q: What is a diagnostic trouble code (DTC)?

- A: A DTC is a code stored in the vehicle’s computer that indicates a specific issue or malfunction.

- Q: Can I clear OBD2 codes myself?

- A: Yes, you can clear OBD2 codes using an OBD2 scanner, but it is important to address the underlying issue first.

- Q: What is live data streaming?

- A: Live data streaming allows you to monitor various engine parameters in real-time, providing valuable diagnostic information.

- Q: Do I need a special OBD2 scanner for my Mercedes-Benz truck?

- A: While a basic OBD2 scanner can read generic codes, a specialized scan tool like the Mercedes-Benz Star Diagnosis system is recommended for in-depth diagnostics.

- Q: Can OBD2 diagnostics help improve fuel economy?

- A: Yes, by identifying and resolving issues that affect engine performance, OBD2 diagnostics can help improve fuel economy.

- Q: Is it safe to drive with the “check engine” light on?

- A: It depends on the severity of the issue. If the light is flashing or accompanied by other symptoms, it is best to seek professional help immediately.

- Q: How often should I perform OBD2 diagnostics on my truck?

- A: You should perform OBD2 diagnostics whenever the “check engine” light comes on or if you notice any performance issues.

- Q: Can OBD2 diagnostics detect transmission problems?

- A: Yes, OBD2 diagnostics can detect transmission problems, but specialized diagnostic procedures may be required for accurate troubleshooting.

27. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Expert Assistance

Need expert assistance with your Mercedes-Benz truck diagnostics? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for personalized support and guidance. Our team of experienced technicians can help you diagnose complex issues, recommend the right diagnostic tools, and provide training and resources to enhance your skills. Whether you are a DIY enthusiast or a professional mechanic, we are here to assist you with all your Mercedes-Benz truck diagnostic needs. Reach out to us at 789 Oak Avenue, Miami, FL 33101, United States, Whatsapp: +1 (641) 206-8880, or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information. Let us help you keep your Mercedes-Benz truck running smoothly and efficiently.

Mercedes-Benz Diagnostic Tool

Mercedes-Benz Diagnostic Tool

Is your truck OBD2 compliant? Don’t let diagnostic challenges slow you down. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN now for expert assistance! Get the right tools, precise diagnostics, and personalized support to keep your Mercedes-Benz truck performing at its best. Dial +1 (641) 206-8880 or visit MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today!