The J1850 Obd2 Female Port is a crucial interface for vehicle diagnostics and data access, offering compatibility with various OBD2 devices and facilitating in-depth vehicle analysis. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we empower Mercedes-Benz owners, automotive technicians, and car enthusiasts with the knowledge and tools needed to effectively utilize this port. Explore its features, applications, and benefits, unlocking a new level of understanding of your vehicle’s performance and health. Enhance your diagnostic capabilities, streamline maintenance, and discover hidden features with our comprehensive support, ensuring you have the expertise and resources for optimal vehicle management.

Contents

- 1. Understanding the J1850 OBD2 Female Port

- 1.1 What Is the J1850 Protocol?

- 1.2 What Is an OBD2 Female Port?

- 1.3 What Is a J1850 OBD2 Female Port?

- 2. Key Features of the J1850 OBD2 Female Port

- 2.1 Protocol Support

- 2.2 Pin Configuration

- 2.3 Diagnostic Capabilities

- 2.4 Compatibility

- 3. Applications of the J1850 OBD2 Female Port

- 3.1 Vehicle Diagnostics

- 3.2 Performance Monitoring

- 3.3 Emissions Testing

- 3.4 Data Logging

- 4. Benefits of Using the J1850 OBD2 Female Port

- 4.1 Accurate Diagnostics

- 4.2 Cost Savings

- 4.3 Improved Vehicle Performance

- 4.4 Enhanced Vehicle Longevity

- 5. How to Use the J1850 OBD2 Female Port

- 5.1 Selecting a Diagnostic Tool

- 5.2 Connecting the Diagnostic Tool

- 5.3 Reading Diagnostic Trouble Codes (DTCs)

- 5.4 Monitoring Live Data

- 5.5 Clearing Diagnostic Trouble Codes (DTCs)

- 6. Common Issues and Troubleshooting

- 6.1 No Communication

- 6.2 Incorrect Data

- 6.3 Inaccurate DTCs

- 7. Advanced Diagnostics with J1850 OBD2

- 7.1 Custom Parameter IDs (PIDs)

- 7.2 Bi-Directional Control

- 7.3 ECU Programming

- 8. J1850 OBD2 and Mercedes-Benz Vehicles

- 8.1 Compatibility

- 8.2 Diagnostic Tools for Mercedes-Benz

- 8.3 Unlocking Hidden Features

- 9. Maintaining Your Mercedes-Benz with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 9.1 Comprehensive Diagnostic Support

- 9.2 Expert Guidance and Tutorials

- 9.3 High-Quality Diagnostic Tools

- 10. Call to Action

- 11. What is the Difference Between J1850 VPW and J1850 PWM?

- 12. Can I Use a Standard OBD2 Scanner on a J1850 OBD2 Port?

- 13. Where Is the OBD2 Port Located in My Car?

- 14. What Does a Diagnostic Trouble Code (DTC) Mean?

- 15. How Do I Clear Diagnostic Trouble Codes (DTCs)?

- 16. What Is Live Data and Why Is It Important?

- 17. What Are Readiness Monitors and How Do They Work?

- 18. Can I Use an OBD2 Port to Track My Car’s Location?

- 19. Is It Safe to Leave an OBD2 Scanner Plugged In All the Time?

- 20. How Can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Help Me?

- 11. Delving Deeper: The Technical Nuances of J1850 OBD2 Protocol

- 11.1 Understanding J1850 Frame Structure

- 11.2 J1850 VPW Signal Characteristics

- 11.3 J1850 PWM Signal Characteristics

- 11.4 Addressing Modes in J1850

- 11.5 Error Detection and Handling

- 12. Practical Applications: Diagnosing Common Issues with J1850 OBD2

- 12.1 Diagnosing Misfires

- 12.2 Troubleshooting Transmission Problems

- 12.3 Addressing ABS and Brake Issues

- 12.4 Diagnosing Airbag System Malfunctions

- 12.5 Identifying Fuel System Problems

- 13. Enhancing Vehicle Performance and Customization

- 13.1 Performance Tuning

- 13.2 Data Logging for Performance Analysis

- 13.3 Custom Gauges and Displays

- 13.4 Security and Anti-Theft Systems

- 13.5 Integrating with Telematics Systems

- 14. Safety Considerations When Working with J1850 OBD2 Systems

- 14.1 Electrical Safety

- 14.2 Airbag System Safety

- 14.3 Fuel System Safety

- 14.4 Handling Hazardous Materials

- 14.5 Vehicle Stability

- 15. The Future of J1850 OBD2: Legacy Systems and Modern Adaptations

- 15.1 Legacy Systems and Continued Support

- 15.2 Adapting J1850 to Modern Systems

- 15.3 Aftermarket Solutions

- 15.4 The Role of Open-Source Development

- 15.5 The Importance of Training and Education

- 16. Frequently Asked Questions (FAQs) About J1850 OBD2 Female Ports

- 16.1 What Diagnostic Tools Are Compatible With J1850 OBD2 Female Ports?

- 16.2 How Do I Identify If My Vehicle Uses J1850 Protocol?

- 16.3 Can J1850 OBD2 Ports Be Used for Performance Tuning?

- 16.4 What Safety Precautions Should I Take When Working With J1850 OBD2 Systems?

- 16.5 How Do I Diagnose a No-Communication Issue With a J1850 OBD2 Port?

- 16.6 Can I Use a J1850 Adapter for Modern OBD2 Scanners?

- 16.7 How Do I Clear Diagnostic Trouble Codes (DTCs) From a J1850 OBD2 System?

- 16.8 What Is the Difference Between Physical and Functional Addressing in J1850?

- 16.9 How Can I Monitor Live Data From a J1850 OBD2 Port?

- 16.10 Are There Open-Source Tools for Working With J1850 OBD2 Systems?

- 17. Conclusion: The Enduring Relevance of J1850 OBD2

1. Understanding the J1850 OBD2 Female Port

1.1 What Is the J1850 Protocol?

The J1850 protocol is an older communication standard used in early OBD2 systems, primarily in General Motors (GM) and Ford vehicles. According to SAE standards, J1850 is defined by two variants: J1850 VPW (Variable Pulse Width) and J1850 PWM (Pulse Width Modulation). These protocols enable communication between a vehicle’s various electronic control units (ECUs) and external diagnostic tools.

1.2 What Is an OBD2 Female Port?

The On-Board Diagnostics II (OBD2) female port is a standardized 16-pin connector found in most vehicles manufactured after 1996. It provides access to the vehicle’s diagnostic data, allowing technicians and car owners to read trouble codes, monitor sensor data, and perform other diagnostic functions. The standardization of the OBD2 port ensures compatibility across different vehicle makes and models, making diagnostics more accessible.

1.3 What Is a J1850 OBD2 Female Port?

The J1850 OBD2 female port refers to an OBD2 connector that supports the J1850 communication protocol. This type of port is essential for diagnosing and interacting with older vehicles that utilize J1850 VPW or J1850 PWM protocols. Without a compatible J1850 OBD2 female port, diagnostic tools designed for these protocols cannot effectively communicate with the vehicle’s ECUs.

2. Key Features of the J1850 OBD2 Female Port

2.1 Protocol Support

The J1850 OBD2 female port supports both J1850 VPW and J1850 PWM protocols, making it versatile for use with a range of older vehicles. According to SAE J1850 standards, VPW operates at 10.4 kbps and PWM operates at 41.6 kbps. This dual protocol support ensures compatibility with various GM and Ford models from the late 1990s and early 2000s.

2.2 Pin Configuration

The 16-pin configuration of the OBD2 port includes specific pins designated for the J1850 protocol. Typically, Pin 2 is used for J1850 VPW, while Pin 10 is used for J1850 PWM. The standardized pinout ensures that diagnostic tools can reliably connect and communicate with the vehicle’s systems, enabling accurate data retrieval and diagnostics.

2.3 Diagnostic Capabilities

With the J1850 OBD2 female port, users can access a wide range of diagnostic information, including:

- Diagnostic Trouble Codes (DTCs): Retrieve codes indicating specific issues within the vehicle’s systems.

- Live Sensor Data: Monitor real-time data from various sensors, such as engine temperature, oxygen sensor readings, and throttle position.

- Freeze Frame Data: View data captured at the moment a DTC was triggered, providing valuable context for troubleshooting.

2.4 Compatibility

The J1850 OBD2 female port is compatible with a variety of diagnostic tools, including handheld scanners, PC-based software, and smartphone apps. This compatibility allows users to choose the tool that best fits their needs and budget. Ensure the diagnostic tool specifically supports the J1850 protocol for effective communication.

3. Applications of the J1850 OBD2 Female Port

3.1 Vehicle Diagnostics

The primary application of the J1850 OBD2 female port is vehicle diagnostics. Technicians and car owners can use diagnostic tools to read DTCs, diagnose issues, and perform necessary repairs. For instance, if the check engine light is illuminated, the J1850 OBD2 female port can be used to identify the specific problem, such as a faulty oxygen sensor or a misfiring cylinder.

3.2 Performance Monitoring

The J1850 OBD2 female port allows users to monitor vehicle performance in real-time. By accessing live sensor data, users can track parameters such as engine speed (RPM), coolant temperature, and fuel consumption. This information is valuable for identifying potential problems before they escalate and for optimizing vehicle performance.

3.3 Emissions Testing

The J1850 OBD2 female port is crucial for emissions testing. Many states and countries require vehicles to undergo emissions testing to ensure they meet environmental standards. The OBD2 port allows testing equipment to verify the functionality of emissions-related components, such as the catalytic converter and oxygen sensors.

3.4 Data Logging

The J1850 OBD2 female port can be used for data logging, where vehicle data is recorded over time for later analysis. This is particularly useful for diagnosing intermittent problems or for tracking vehicle performance under various driving conditions. Data logging can provide valuable insights into the vehicle’s behavior and help identify patterns that might not be apparent during a static diagnostic test.

4. Benefits of Using the J1850 OBD2 Female Port

4.1 Accurate Diagnostics

The J1850 OBD2 female port provides accurate and reliable diagnostic information, enabling technicians and car owners to identify and address vehicle problems effectively. Access to DTCs, live sensor data, and freeze frame data allows for a comprehensive understanding of the vehicle’s condition.

4.2 Cost Savings

By using the J1850 OBD2 female port for DIY diagnostics, car owners can save money on repair costs. Identifying problems early and performing simple repairs themselves can prevent more costly damage in the future. Additionally, knowing the exact issue before visiting a mechanic can help avoid unnecessary repairs and charges.

4.3 Improved Vehicle Performance

Monitoring vehicle performance through the J1850 OBD2 female port can lead to improved fuel efficiency and overall vehicle performance. By tracking parameters such as fuel consumption and engine temperature, users can identify areas for optimization and make adjustments to improve their vehicle’s efficiency.

4.4 Enhanced Vehicle Longevity

Regular diagnostics and maintenance facilitated by the J1850 OBD2 female port can extend the life of the vehicle. Identifying and addressing problems early prevents them from causing further damage and ensures that the vehicle operates at its best for longer.

5. How to Use the J1850 OBD2 Female Port

5.1 Selecting a Diagnostic Tool

Choose a diagnostic tool that supports the J1850 protocol. There are many options available, ranging from inexpensive handheld scanners to advanced PC-based software. Consider factors such as features, ease of use, and compatibility with your vehicle when selecting a tool.

5.2 Connecting the Diagnostic Tool

Locate the OBD2 port in your vehicle, typically found under the dashboard on the driver’s side. Plug the diagnostic tool into the OBD2 female port, ensuring a secure connection. Turn on the vehicle’s ignition to power the diagnostic tool.

5.3 Reading Diagnostic Trouble Codes (DTCs)

Use the diagnostic tool to read any stored DTCs. The tool will display the codes along with a brief description of the problem. Consult a repair manual or online resources to understand the meaning of each code and potential solutions.

5.4 Monitoring Live Data

Use the diagnostic tool to monitor live sensor data. Select the parameters you want to track, such as engine speed, coolant temperature, and oxygen sensor readings. Observe the data to identify any abnormalities or trends that may indicate a problem.

5.5 Clearing Diagnostic Trouble Codes (DTCs)

After performing repairs, use the diagnostic tool to clear the DTCs. This will turn off the check engine light and reset the vehicle’s diagnostic system. Note that clearing the codes does not fix the underlying problem, so it’s essential to address the root cause before clearing the codes.

6. Common Issues and Troubleshooting

6.1 No Communication

If the diagnostic tool fails to communicate with the vehicle, check the following:

- Ensure the diagnostic tool is compatible with the J1850 protocol.

- Verify the connection to the OBD2 female port is secure.

- Check the vehicle’s battery voltage and ensure it is within the normal range.

- Inspect the OBD2 port for any damage or corrosion.

6.2 Incorrect Data

If the diagnostic tool displays incorrect or inconsistent data, try the following:

- Verify the diagnostic tool is using the correct vehicle profile.

- Check for any software updates for the diagnostic tool.

- Consult the vehicle’s repair manual to confirm the expected values for the sensors being monitored.

6.3 Inaccurate DTCs

If the diagnostic tool provides inaccurate DTCs, consider the following:

- Use a different diagnostic tool to verify the codes.

- Consult multiple sources to confirm the meaning of the codes.

- Inspect the affected components and wiring for any damage or corrosion.

7. Advanced Diagnostics with J1850 OBD2

7.1 Custom Parameter IDs (PIDs)

Advanced users can utilize custom Parameter IDs (PIDs) to access additional data not available through standard OBD2 PIDs. According to SAE J1979, custom PIDs can be defined for specific vehicle models. This requires a deeper understanding of the vehicle’s communication protocols and the use of specialized diagnostic tools.

7.2 Bi-Directional Control

Some advanced diagnostic tools offer bi-directional control, allowing users to send commands to the vehicle’s ECUs. This can be used to perform functions such as activating solenoids, testing actuators, and resetting adaptive parameters. Bi-directional control requires caution and a thorough understanding of the vehicle’s systems.

7.3 ECU Programming

In certain cases, the J1850 OBD2 female port can be used for ECU programming or re-flashing. This involves updating the software on the vehicle’s ECUs to improve performance, fix bugs, or add new features. ECU programming requires specialized equipment and expertise and should only be performed by trained professionals.

8. J1850 OBD2 and Mercedes-Benz Vehicles

8.1 Compatibility

While Mercedes-Benz vehicles primarily use CAN (Controller Area Network) communication protocols, understanding J1850 OBD2 can still be beneficial. Some older Mercedes-Benz models or aftermarket systems might utilize J1850 for specific functions. Additionally, knowledge of J1850 can be helpful when working with a variety of vehicles in a professional automotive setting.

8.2 Diagnostic Tools for Mercedes-Benz

For Mercedes-Benz vehicles, it’s essential to use diagnostic tools that specifically support the CAN protocol and Mercedes-Benz diagnostic standards. These tools provide comprehensive diagnostic capabilities, including reading DTCs, monitoring live data, performing adaptations, and programming ECUs. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer a range of diagnostic tools tailored for Mercedes-Benz vehicles.

8.3 Unlocking Hidden Features

With the right diagnostic tools and expertise, it’s possible to unlock hidden features in Mercedes-Benz vehicles. These features can include customizing lighting settings, enabling performance displays, and adjusting vehicle parameters. Unlocking hidden features requires a thorough understanding of the vehicle’s systems and the use of advanced diagnostic tools.

9. Maintaining Your Mercedes-Benz with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

9.1 Comprehensive Diagnostic Support

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive diagnostic support for Mercedes-Benz vehicles. Our range of diagnostic tools, combined with our expert knowledge, ensures that you can accurately diagnose and address any issues with your vehicle. Whether you’re a DIY enthusiast or a professional technician, we have the resources you need to keep your Mercedes-Benz running smoothly.

9.2 Expert Guidance and Tutorials

We offer expert guidance and tutorials on using diagnostic tools and performing repairs on Mercedes-Benz vehicles. Our step-by-step guides cover a wide range of topics, from reading DTCs to performing advanced programming. With our support, you can confidently tackle maintenance and repairs on your Mercedes-Benz.

9.3 High-Quality Diagnostic Tools

We offer a selection of high-quality diagnostic tools specifically designed for Mercedes-Benz vehicles. These tools provide comprehensive diagnostic capabilities, including reading DTCs, monitoring live data, performing adaptations, and programming ECUs. Our tools are designed to be user-friendly and reliable, ensuring accurate and efficient diagnostics.

10. Call to Action

Ready to take control of your Mercedes-Benz diagnostics and maintenance? Contact us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert advice on selecting the right diagnostic tools, unlocking hidden features, and performing essential repairs. Our team is here to help you get the most out of your Mercedes-Benz.

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Don’t wait – empower yourself with the knowledge and tools to keep your Mercedes-Benz in top condition. Contact us today!

11. What is the Difference Between J1850 VPW and J1850 PWM?

The J1850 protocol has two main variants: J1850 VPW (Variable Pulse Width) and J1850 PWM (Pulse Width Modulation). J1850 VPW is primarily used by General Motors (GM), while J1850 PWM is used by Ford. J1850 VPW operates at a data rate of 10.4 kbps, while J1850 PWM operates at 41.6 kbps. This difference in data rate and modulation technique makes them incompatible, requiring specific diagnostic tools for each protocol.

12. Can I Use a Standard OBD2 Scanner on a J1850 OBD2 Port?

Yes, a standard OBD2 scanner can be used on a J1850 OBD2 port, but it must support the J1850 protocol to properly communicate with the vehicle. Most modern OBD2 scanners are designed to support multiple protocols, including J1850 VPW and J1850 PWM. However, it’s essential to verify that the scanner specifically lists J1850 compatibility to ensure accurate diagnostics.

13. Where Is the OBD2 Port Located in My Car?

The OBD2 port is typically located under the dashboard on the driver’s side of the vehicle. Common locations include near the steering column, in the center console, or behind a small access panel. Refer to your vehicle’s owner’s manual for the exact location of the OBD2 port, as it may vary depending on the make and model.

14. What Does a Diagnostic Trouble Code (DTC) Mean?

A Diagnostic Trouble Code (DTC) is a code stored in the vehicle’s computer that indicates a specific problem or malfunction. DTCs are standardized across the automotive industry and provide a quick way to identify issues with various systems, such as the engine, transmission, and emissions control. Each DTC corresponds to a specific fault, allowing technicians to quickly diagnose and repair the problem.

15. How Do I Clear Diagnostic Trouble Codes (DTCs)?

To clear Diagnostic Trouble Codes (DTCs), use an OBD2 scanner to connect to the vehicle’s computer. Navigate to the function that allows you to clear or reset the codes. After clearing the codes, the check engine light should turn off. However, if the underlying problem persists, the DTCs will reappear.

16. What Is Live Data and Why Is It Important?

Live data refers to the real-time information from the vehicle’s sensors and systems that can be monitored using an OBD2 scanner. Monitoring live data is essential for diagnosing problems, as it allows you to see how the vehicle is performing under various conditions. This can help identify intermittent issues or track the performance of specific components.

17. What Are Readiness Monitors and How Do They Work?

Readiness monitors are internal tests performed by the vehicle’s computer to ensure that various systems are functioning correctly. These monitors are essential for emissions testing, as they indicate whether the vehicle is ready to be tested. Common readiness monitors include the oxygen sensor monitor, catalytic converter monitor, and evaporative system monitor.

18. Can I Use an OBD2 Port to Track My Car’s Location?

Yes, an OBD2 port can be used to track a car’s location by plugging in a GPS tracker that connects to the OBD2 port. These trackers draw power from the OBD2 port and transmit location data to a smartphone app or web-based platform. This can be useful for fleet management, theft recovery, or monitoring driving habits.

19. Is It Safe to Leave an OBD2 Scanner Plugged In All the Time?

It is generally safe to leave an OBD2 scanner plugged in all the time, but there are a few potential concerns. Some scanners may draw a small amount of power, which could drain the battery if the vehicle is not driven for an extended period. Additionally, some scanners may interfere with the vehicle’s electronic systems. If you plan to leave a scanner plugged in, choose a reputable brand and monitor the vehicle’s battery voltage.

20. How Can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Help Me?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive support for Mercedes-Benz vehicle diagnostics, maintenance, and customization. We provide high-quality diagnostic tools, expert guidance, and detailed tutorials to help you get the most out of your Mercedes-Benz. Contact us today to learn more about our products and services.

11. Delving Deeper: The Technical Nuances of J1850 OBD2 Protocol

11.1 Understanding J1850 Frame Structure

The J1850 protocol, whether VPW or PWM, employs a specific frame structure for data transmission. According to the SAE J1850 standard, a typical frame includes a start of message (SOM) field, a header containing source and destination addresses, data bytes, a checksum for error detection, and an end of message (EOM) field. This structure ensures organized and reliable communication between ECUs and diagnostic tools.

11.2 J1850 VPW Signal Characteristics

J1850 VPW uses a variable pulse width to represent binary data. A short pulse indicates a ‘0’, while a long pulse indicates a ‘1’. The timing of these pulses is critical for accurate data interpretation. The protocol operates on a single-wire bus, simplifying wiring but also making it more susceptible to noise. GM vehicles commonly used this protocol in the late 1990s and early 2000s.

11.3 J1850 PWM Signal Characteristics

J1850 PWM, primarily used by Ford, utilizes pulse width modulation where the width of the pulse determines the binary value. It operates at a faster data rate of 41.6 kbps compared to VPW. PWM uses a differential bus, which provides better noise immunity. This protocol was prevalent in Ford vehicles during the same period as VPW in GM vehicles.

11.4 Addressing Modes in J1850

J1850 supports different addressing modes, including physical and functional addressing. Physical addressing involves direct communication between two specific nodes, while functional addressing allows a message to be broadcast to multiple nodes that perform a specific function. According to the J1850 standard, the address field in the header specifies the type of addressing being used.

11.5 Error Detection and Handling

The J1850 protocol incorporates error detection mechanisms, such as checksums, to ensure data integrity. The checksum is calculated based on the data in the frame, and the receiver verifies this checksum to detect errors. If an error is detected, the frame is discarded, and a retransmission may be requested.

12. Practical Applications: Diagnosing Common Issues with J1850 OBD2

12.1 Diagnosing Misfires

Misfires are a common issue in older vehicles, and the J1850 OBD2 port can be instrumental in diagnosing them. By reading DTCs related to misfires, such as P0300 (Random Misfire Detected), P0301 (Cylinder 1 Misfire), etc., technicians can pinpoint the affected cylinder and investigate the cause. Live data from the oxygen sensors and fuel trims can further aid in identifying the root cause, such as faulty spark plugs, ignition coils, or fuel injectors.

12.2 Troubleshooting Transmission Problems

The J1850 OBD2 port can also be used to diagnose transmission problems. DTCs related to the transmission, such as P0700 (Transmission Control System Malfunction), can indicate issues with the transmission control module (TCM) or related sensors. Monitoring live data from the transmission, such as gear ratios and torque converter lockup, can help identify mechanical or electrical problems.

12.3 Addressing ABS and Brake Issues

ABS (Anti-lock Braking System) and brake issues can be diagnosed using the J1850 OBD2 port. DTCs related to the ABS, such as C0040 (Right Front Wheel Speed Sensor Circuit Malfunction), can help identify problems with wheel speed sensors, ABS module, or hydraulic components. Live data from the wheel speed sensors can be monitored to verify their functionality and identify any discrepancies.

12.4 Diagnosing Airbag System Malfunctions

Airbag system malfunctions can be diagnosed using the J1850 OBD2 port, although safety precautions must be taken when working with airbag systems. DTCs related to the airbag system, such as B0001 (Driver Airbag Circuit Open), can indicate problems with the airbag module, sensors, or wiring. It’s crucial to consult the vehicle’s service manual and follow proper procedures when diagnosing and repairing airbag systems.

12.5 Identifying Fuel System Problems

Fuel system problems can be identified using the J1850 OBD2 port. DTCs related to the fuel system, such as P0171 (System Too Lean) or P0172 (System Too Rich), can indicate issues with the fuel pump, fuel injectors, or oxygen sensors. Monitoring live data from the oxygen sensors, fuel trims, and mass airflow (MAF) sensor can help pinpoint the cause of the fuel system problem.

13. Enhancing Vehicle Performance and Customization

13.1 Performance Tuning

While limited compared to modern CAN-based systems, the J1850 OBD2 port can be used for basic performance tuning. Some aftermarket tuning devices connect to the J1850 port and allow adjustments to parameters such as fuel maps and ignition timing. However, it’s essential to proceed with caution and consult with a qualified tuning professional to avoid damaging the vehicle.

13.2 Data Logging for Performance Analysis

The J1850 OBD2 port can be used for data logging, which involves recording vehicle data over time for performance analysis. This data can be used to identify areas for improvement and optimize vehicle performance. Data logging can be particularly useful for diagnosing performance issues or tracking changes made during tuning.

13.3 Custom Gauges and Displays

The J1850 OBD2 port can be connected to custom gauges and displays that show real-time vehicle data. These gauges can provide valuable information to the driver, such as engine temperature, boost pressure, and air-fuel ratio. Custom displays can also be used to monitor performance parameters and alert the driver to potential problems.

13.4 Security and Anti-Theft Systems

The J1850 OBD2 port can be integrated with security and anti-theft systems. These systems can use the OBD2 port to monitor vehicle activity and alert the owner if the vehicle is being tampered with or stolen. Some systems can even disable the vehicle remotely via the OBD2 port.

13.5 Integrating with Telematics Systems

The J1850 OBD2 port can be integrated with telematics systems that provide vehicle tracking, diagnostics, and remote control capabilities. These systems can be used for fleet management, usage-based insurance, and remote diagnostics. Telematics systems can also provide valuable data for vehicle maintenance and repair.

14. Safety Considerations When Working with J1850 OBD2 Systems

14.1 Electrical Safety

When working with J1850 OBD2 systems, it’s essential to follow proper electrical safety procedures. Disconnect the vehicle’s battery before performing any electrical work to prevent accidental shorts or shocks. Use insulated tools and wear appropriate personal protective equipment (PPE) to protect against electrical hazards.

14.2 Airbag System Safety

When working with airbag systems, it’s crucial to take extra precautions. Always disconnect the vehicle’s battery and wait at least 10 minutes before working on the airbag system to allow the capacitors to discharge. Consult the vehicle’s service manual and follow proper procedures when diagnosing and repairing airbag systems.

14.3 Fuel System Safety

When working with fuel systems, it’s essential to take precautions to prevent fires or explosions. Work in a well-ventilated area and avoid sparks or open flames. Disconnect the vehicle’s battery and relieve fuel pressure before disconnecting any fuel lines or components.

14.4 Handling Hazardous Materials

When working on vehicles, you may encounter hazardous materials such as oil, coolant, and brake fluid. Handle these materials with care and dispose of them properly according to local regulations. Wear appropriate PPE, such as gloves and eye protection, to protect against exposure to hazardous materials.

14.5 Vehicle Stability

When working on a vehicle, ensure that it is properly supported and stable. Use jack stands to support the vehicle after lifting it with a jack. Never work under a vehicle that is only supported by a jack.

15. The Future of J1850 OBD2: Legacy Systems and Modern Adaptations

15.1 Legacy Systems and Continued Support

While J1850 is an older protocol, many vehicles still in operation use it. Therefore, continued support for J1850 OBD2 is essential. Diagnostic tool manufacturers and automotive technicians need to maintain the capability to diagnose and repair these vehicles.

15.2 Adapting J1850 to Modern Systems

In some cases, J1850 systems are being adapted to work with modern CAN-based systems. This may involve the use of protocol converters or gateways that translate data between the two protocols. This allows older vehicles to integrate with modern diagnostic and telematics systems.

15.3 Aftermarket Solutions

Aftermarket solutions are available to add J1850 OBD2 compatibility to vehicles that don’t have it. These solutions may involve installing an aftermarket ECU or diagnostic port that supports J1850. This can be useful for connecting older vehicles to modern diagnostic tools or telematics systems.

15.4 The Role of Open-Source Development

Open-source development is playing a significant role in supporting J1850 OBD2. Open-source software and hardware tools are available for diagnosing, tuning, and integrating with J1850 systems. This allows enthusiasts and researchers to develop custom solutions and contribute to the continued support of J1850.

15.5 The Importance of Training and Education

Training and education are crucial for technicians and enthusiasts working with J1850 OBD2 systems. Understanding the J1850 protocol, its limitations, and its applications is essential for effective diagnostics and repair. Continued education and training can help ensure that J1850 systems are properly maintained and supported.

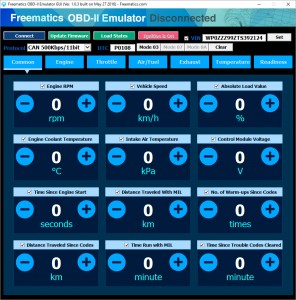

Freematics Emulator GUI OBD PIDs

Freematics Emulator GUI OBD PIDs

16. Frequently Asked Questions (FAQs) About J1850 OBD2 Female Ports

16.1 What Diagnostic Tools Are Compatible With J1850 OBD2 Female Ports?

Diagnostic tools compatible with J1850 OBD2 female ports include those that support the J1850 VPW and J1850 PWM protocols. Modern OBD2 scanners often support multiple protocols, but it’s important to verify J1850 compatibility.

16.2 How Do I Identify If My Vehicle Uses J1850 Protocol?

You can identify if your vehicle uses the J1850 protocol by checking the vehicle’s service manual or consulting online resources. Generally, GM and Ford vehicles from the late 1990s and early 2000s are likely to use J1850 VPW or J1850 PWM.

16.3 Can J1850 OBD2 Ports Be Used for Performance Tuning?

Yes, J1850 OBD2 ports can be used for basic performance tuning, although capabilities are limited compared to modern CAN-based systems. Aftermarket tuning devices can connect to the J1850 port and allow adjustments to fuel maps and ignition timing.

16.4 What Safety Precautions Should I Take When Working With J1850 OBD2 Systems?

Safety precautions include disconnecting the vehicle’s battery before performing electrical work, taking extra precautions when working with airbag systems, and ensuring the vehicle is properly supported when lifted.

16.5 How Do I Diagnose a No-Communication Issue With a J1850 OBD2 Port?

To diagnose a no-communication issue, check the diagnostic tool’s compatibility, verify the connection to the OBD2 female port, check the vehicle’s battery voltage, and inspect the OBD2 port for damage.

16.6 Can I Use a J1850 Adapter for Modern OBD2 Scanners?

Yes, you can use a J1850 adapter for modern OBD2 scanners to communicate with vehicles that use the J1850 protocol. These adapters convert the J1850 signal to a format compatible with modern scanners.

16.7 How Do I Clear Diagnostic Trouble Codes (DTCs) From a J1850 OBD2 System?

To clear DTCs from a J1850 OBD2 system, use an OBD2 scanner to connect to the vehicle’s computer and navigate to the function that allows you to clear or reset the codes.

16.8 What Is the Difference Between Physical and Functional Addressing in J1850?

Physical addressing involves direct communication between two specific nodes, while functional addressing allows a message to be broadcast to multiple nodes that perform a specific function.

16.9 How Can I Monitor Live Data From a J1850 OBD2 Port?

You can monitor live data from a J1850 OBD2 port using a diagnostic tool that supports the J1850 protocol. Select the parameters you want to track, such as engine speed, coolant temperature, and oxygen sensor readings.

16.10 Are There Open-Source Tools for Working With J1850 OBD2 Systems?

Yes, there are open-source software and hardware tools available for diagnosing, tuning, and integrating with J1850 systems. These tools allow enthusiasts and researchers to develop custom solutions.

17. Conclusion: The Enduring Relevance of J1850 OBD2

The J1850 OBD2 female port remains a relevant and important interface for vehicle diagnostics and data access, particularly for older vehicles. Understanding the J1850 protocol, its features, and its applications is essential for automotive technicians and enthusiasts alike. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are committed to providing the knowledge, tools, and support you need to effectively utilize J1850 OBD2 and keep your vehicle running smoothly.

Remember, whether you are diagnosing a misfire, troubleshooting a transmission problem, or simply monitoring your vehicle’s performance, the J1850 OBD2 female port offers valuable insights and capabilities. Embrace the power of vehicle diagnostics and take control of your Mercedes-Benz’s health with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

Contact us today!

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN