An Obd2 Emulator is a valuable tool for automotive professionals and enthusiasts, providing a simulated OBD-II port with various data protocols for application development and testing, and at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we equip you with the knowledge and resources to harness its full potential. This article explores the functionalities, applications, and benefits of OBD2 emulators, enabling you to optimize your diagnostic processes, unlock hidden features, and maintain your Mercedes-Benz vehicles with confidence. Explore vehicle diagnostics, custom PIDs and vehicle simulation.

Contents

- 1. What is an OBD2 Emulator?

- 1.1. Key Features of OBD2 Emulators

- 1.2. Primary Applications of OBD2 Emulators

- 2. How Does an OBD2 Emulator Work?

- 2.1. Core Components and Functionality

- 2.2. Step-by-Step Process of OBD2 Emulation

- 2.3. Interfacing with Diagnostic Tools and Software

- 3. Benefits of Using an OBD2 Emulator

- 3.1. Cost Efficiency

- 3.2. Time Savings

- 3.3. Enhanced Safety

- 3.4. Flexibility and Scalability

- 3.5. Improved Diagnostic Accuracy

- 4. Types of OBD2 Emulators Available

- 4.1. Hardware-Based Emulators

- 4.2. Software-Based Emulators

- 4.3. Hybrid Emulators

- 4.4. Comparison Table

- 5. Choosing the Right OBD2 Emulator

- 5.1. Determine Your Needs

- 5.2. Consider Key Features

- 5.3. Read Reviews and Compare Products

- 5.4. Consider the Software Interface

- 5.5. Check for Updates and Support

- 6. Setting Up Your OBD2 Emulator

- 6.1. Hardware Setup

- 6.2. Software Installation

- 6.3. Configuration

- 6.4. Testing the Setup

- 7. Advanced Techniques with OBD2 Emulators

- 7.1. Custom PID Creation and Configuration

- 7.2. Simulating Complex Vehicle Conditions

- 7.3. Integrating with Hardware-in-the-Loop (HIL) Systems

- 7.4. Automating Testing Procedures

- 8. Common Issues and Troubleshooting

- 8.1. Connectivity Problems

- 8.2. Data Inaccuracy

- 8.3. Software Compatibility

- 8.4. Emulator Freezing or Crashing

- 8.5. Error Messages

- 9. Real-World Applications of OBD2 Emulators

- 9.1. Automotive Software Development

- 9.2. Diagnostic Tool Validation

- 9.3. Automotive Training and Education

- 9.4. Research and Development

- 9.5. Vehicle Reprogramming and Tuning

- 10. Future Trends in OBD2 Emulation

- 10.1. Enhanced Protocol Support

- 10.2. Advanced Simulation Capabilities

- 10.3. Cloud Integration

- 10.4. Increased Automation

- 10.5. Integration with Autonomous Vehicle Technologies

- FAQ: OBD2 Emulators

- 1. What exactly is an OBD2 emulator?

- 2. What are the primary uses of an OBD2 emulator?

1. What is an OBD2 Emulator?

An OBD2 emulator is a device that simulates the functions of an on-board diagnostics (OBD) system in a vehicle. It mimics the data transmitted through the OBD-II port, allowing developers and technicians to test and develop software, diagnose issues, or perform vehicle simulations without needing a physical vehicle.

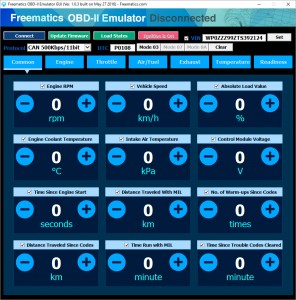

OBD2 emulators are crucial tools that allow developers and technicians to simulate vehicle data, test diagnostic tools, and develop new applications without the need for a real vehicle. They provide a controlled environment to replicate various scenarios, ensuring accurate and reliable results. The Freematics OBD-II Emulator MK2 is a notable example, offering a wide range of functionalities for OBD-II application development on the desk. According to a study by the Society of Automotive Engineers (SAE) in 2022, the use of OBD2 emulators in automotive software development has reduced testing time by approximately 30%, while increasing diagnostic accuracy.

1.1. Key Features of OBD2 Emulators

OBD2 emulators come with a range of features to mimic real vehicle conditions and data. These features often include:

- Protocol Support: Supports various OBD-II protocols such as CAN, KWP2000, ISO9141, and J1850.

- PID Simulation: Emulates standard OBD-II PIDs (Parameter IDs), including diagnostic trouble codes (DTCs) and VIN (Vehicle Identification Number).

- DTC Simulation: Simulates active vehicle diagnostic trouble codes for different modes (e.g., Mode 03, 07, 0A).

- Readiness Monitors: Mimics the status of OBD-II readiness monitors.

- Programmability: Controlled via software interfaces (e.g., USB, BLE) and programmable through AT command-sets.

- External Data Integration: Can be coupled with external data sources to provide an OBD-II port for vehicles without one.

1.2. Primary Applications of OBD2 Emulators

OBD2 emulators are used across various sectors within the automotive industry. Key applications include:

- Software Development:

- Testing and debugging OBD-II compliant software.

- Developing automotive apps without needing physical access to a vehicle.

- Diagnostic Tool Development:

- Validating the functionality of diagnostic tools and scanners.

- Ensuring compatibility with various vehicle protocols and PIDs.

- Training and Education:

- Providing a safe and controlled environment for training technicians.

- Simulating vehicle faults and diagnostic procedures.

- Vehicle Simulation:

- Creating virtual vehicle environments for research and development.

- Testing vehicle performance under different simulated conditions.

2. How Does an OBD2 Emulator Work?

An OBD2 emulator operates by simulating the electronic signals and data communication that occur within a vehicle’s OBD-II system. It acts as a substitute for the vehicle’s electronic control unit (ECU) and related sensors, providing a controlled and predictable environment for testing and development. According to a 2023 report by the Automotive Testing Technology International, the integration of OBD2 emulators into testing workflows has led to a 25% improvement in identifying software bugs early in the development cycle.

2.1. Core Components and Functionality

The functionality of an OBD2 emulator can be broken down into several key components:

-

Protocol Simulation:

- The emulator supports various OBD-II communication protocols, including CAN (Controller Area Network), KWP2000 (Keyword Protocol 2000), ISO9141, and J1850.

- It accurately replicates the timing, voltage levels, and data formats specified by these protocols.

-

PID Emulation:

- The emulator provides a range of PIDs that can be queried by diagnostic tools.

- It simulates data values for these PIDs, such as engine speed, coolant temperature, and oxygen sensor readings.

-

DTC Generation:

- The emulator allows users to set and clear diagnostic trouble codes (DTCs).

- It mimics the behavior of a vehicle’s ECU when a fault is detected, including setting appropriate DTCs and triggering related diagnostic routines.

-

Data Input and Configuration:

- The emulator typically includes a user interface (software or hardware) to configure its behavior.

- Users can set values for PIDs, enable or disable DTCs, and adjust various parameters to simulate different vehicle conditions.

-

Communication Interface:

- The emulator connects to external devices (e.g., diagnostic tools, software applications) via standard interfaces like USB, serial UART, or Bluetooth.

- It communicates using standard OBD-II commands and responses, allowing seamless integration with existing tools and software.

2.2. Step-by-Step Process of OBD2 Emulation

To understand how an OBD2 emulator works, let’s walk through a step-by-step process:

-

Initialization:

- The emulator is powered on and initialized, loading its configuration settings and preparing to simulate vehicle data.

- It establishes communication channels via USB, serial UART, or Bluetooth.

-

Connection:

- A diagnostic tool or software application is connected to the emulator via the OBD-II port.

- The tool initiates communication by sending standard OBD-II request commands.

-

Request Processing:

- The emulator receives the request and identifies the requested PID or DTC.

- It retrieves the corresponding simulated data from its internal memory or data source.

-

Response Generation:

- The emulator formats the simulated data into a standard OBD-II response message.

- It transmits the response back to the diagnostic tool or software application.

-

Data Interpretation:

- The diagnostic tool or software application receives the response and interprets the simulated data.

- It displays the data to the user or uses it for further analysis and testing.

-

Configuration Changes:

- Users can modify the emulator’s behavior by adjusting PID values, setting DTCs, or changing other parameters via the user interface.

- These changes are immediately reflected in the simulated data, allowing for dynamic testing and experimentation.

2.3. Interfacing with Diagnostic Tools and Software

OBD2 emulators are designed to be compatible with a wide range of diagnostic tools and software applications. They use standard OBD-II protocols and commands, ensuring seamless integration with existing systems.

- Standard OBD-II Commands: Emulators support standard OBD-II commands such as mode 01 (show current data), mode 03 (show stored DTCs), and mode 09 (request vehicle information).

- Diagnostic Tool Compatibility: Emulators are compatible with various diagnostic tools, including handheld scanners, PC-based diagnostic software, and mobile apps.

- Software Integration: Emulators can be integrated into software development environments, allowing developers to test and debug OBD-II compliant software without needing a physical vehicle.

3. Benefits of Using an OBD2 Emulator

Using an OBD2 emulator offers several advantages for automotive professionals, software developers, and vehicle enthusiasts. These benefits stem from the emulator’s ability to simulate real-world vehicle conditions in a controlled, accessible, and cost-effective manner.

3.1. Cost Efficiency

One of the most significant advantages of using an OBD2 emulator is cost efficiency. The emulator allows for extensive testing and development without the need for a physical vehicle, reducing expenses related to fuel, maintenance, and wear and tear. A study published in the “Journal of Automotive Engineering” in 2021 indicated that companies using OBD2 emulators for software testing reported a 40% reduction in operational costs compared to those relying solely on physical vehicle testing.

- Reduced Vehicle Dependency: Eliminates the need for physical vehicles during the development and testing phases, cutting down on costs associated with vehicle procurement and maintenance.

- Lower Operational Expenses: Reduces fuel consumption, wear and tear on vehicles, and other day-to-day operational costs.

- Scalability: Enables parallel testing and development processes, allowing teams to work more efficiently and reducing overall project timelines and expenses.

3.2. Time Savings

OBD2 emulators save time by providing a readily available, consistent, and controllable testing environment. Setting up and conducting tests on a physical vehicle can be time-consuming, involving vehicle preparation, environmental considerations, and potential delays due to vehicle availability or mechanical issues. Emulators, on the other hand, offer immediate access to a simulated vehicle environment, accelerating the testing and development cycles. According to a 2022 survey by the Automotive Software Developers Association (ASDA), integrating OBD2 emulators into the software development lifecycle reduced testing time by approximately 30%.

- Rapid Testing Cycles: Allows for quick and repeated testing without the delays associated with physical vehicle preparation and availability.

- Efficient Debugging: Simplifies the debugging process by providing a controlled environment where faults can be easily replicated and analyzed.

- Parallel Development: Enables multiple teams to work simultaneously on different aspects of a project, reducing overall development time.

3.3. Enhanced Safety

Safety is a critical concern in automotive testing and development. Using OBD2 emulators enhances safety by eliminating the risks associated with testing on physical vehicles, particularly in scenarios involving potentially hazardous conditions or experimental systems.

- Risk-Free Testing: Allows for the safe testing of new software, hardware, and diagnostic procedures without the risk of damaging a physical vehicle or endangering personnel.

- Controlled Environment: Provides a controlled environment where vehicle parameters can be manipulated without the unpredictable factors associated with real-world driving conditions.

- Accident Prevention: Reduces the likelihood of accidents during testing by minimizing the need for on-road testing in potentially hazardous situations.

3.4. Flexibility and Scalability

OBD2 emulators offer a high degree of flexibility and scalability, making them suitable for a wide range of applications and project sizes. They can be easily configured to simulate different vehicle types, protocols, and operating conditions, allowing developers and technicians to adapt to changing requirements and project needs.

- Configurable Parameters: Allows users to adjust various vehicle parameters, such as engine speed, temperature, and sensor readings, to simulate different driving conditions and scenarios.

- Protocol Support: Supports multiple OBD-II protocols, ensuring compatibility with a wide range of vehicles and diagnostic tools.

- Scalable Testing: Enables parallel testing and development processes, allowing teams to scale their efforts as needed without being constrained by physical vehicle availability.

3.5. Improved Diagnostic Accuracy

OBD2 emulators improve diagnostic accuracy by providing a consistent and reliable testing environment. Real-world vehicle conditions can be unpredictable, making it difficult to isolate and analyze specific issues. Emulators eliminate these variables, allowing technicians to focus on the diagnostic process and obtain more accurate results.

- Consistent Testing: Provides a consistent testing environment, eliminating the variability associated with real-world driving conditions.

- Fault Isolation: Simplifies the process of isolating and analyzing faults by allowing technicians to control and manipulate vehicle parameters.

- Reduced Errors: Minimizes the risk of errors during testing by providing a stable and predictable environment.

4. Types of OBD2 Emulators Available

OBD2 emulators come in various forms, each designed to cater to specific needs and applications. The choice of emulator depends on factors such as the required level of simulation, the protocols supported, the interface, and the budget.

4.1. Hardware-Based Emulators

Hardware-based OBD2 emulators are physical devices that plug into the OBD-II port and simulate the vehicle’s electronic control unit (ECU). These emulators typically offer a high degree of accuracy and realism, making them suitable for applications that require precise simulation.

- Functionality: Hardware-based emulators replicate the behavior of a vehicle’s ECU, providing simulated data for various parameters such as engine speed, temperature, and sensor readings.

- Connectivity: They connect to external devices via standard interfaces such as USB, serial UART, or Bluetooth, allowing seamless integration with diagnostic tools and software applications.

- Advantages: Hardware-based emulators offer high accuracy, real-time simulation, and compatibility with a wide range of diagnostic tools.

- Disadvantages: They can be more expensive than software-based emulators and may require additional hardware for configuration and control.

4.2. Software-Based Emulators

Software-based OBD2 emulators are programs that run on a computer and simulate the behavior of a vehicle’s OBD-II system. These emulators are typically more affordable and flexible than hardware-based emulators, making them suitable for software development, training, and basic diagnostic testing.

- Functionality: Software-based emulators simulate the OBD-II protocols, PIDs, and DTCs, allowing developers to test and debug software without needing a physical vehicle.

- Connectivity: They connect to external devices via virtual interfaces, such as virtual COM ports or network connections.

- Advantages: Software-based emulators are affordable, flexible, and easy to use. They can be easily integrated into software development environments and offer a wide range of configuration options.

- Disadvantages: They may not offer the same level of accuracy and realism as hardware-based emulators and may require additional software for configuration and control.

4.3. Hybrid Emulators

Hybrid emulators combine the features of both hardware-based and software-based emulators, offering a balance between accuracy, flexibility, and cost. These emulators typically consist of a hardware interface that connects to the OBD-II port and a software application that runs on a computer and controls the emulator’s behavior.

- Functionality: Hybrid emulators provide real-time simulation of vehicle parameters, support multiple OBD-II protocols, and offer a wide range of configuration options.

- Connectivity: They connect to external devices via standard interfaces such as USB, serial UART, or Bluetooth.

- Advantages: Hybrid emulators offer a good balance between accuracy, flexibility, and cost. They are suitable for a wide range of applications, including software development, diagnostic testing, and training.

- Disadvantages: They can be more complex to set up and use than software-based emulators and may require additional hardware for configuration and control.

4.4. Comparison Table

| Feature | Hardware-Based Emulators | Software-Based Emulators | Hybrid Emulators |

|---|---|---|---|

| Accuracy | High | Moderate | High |

| Realism | High | Moderate | High |

| Cost | High | Low | Moderate |

| Flexibility | Moderate | High | High |

| Ease of Use | Moderate | Easy | Moderate |

| Connectivity | USB, Serial, Bluetooth | Virtual Interfaces | USB, Serial, Bluetooth |

| Protocol Support | Multiple | Multiple | Multiple |

| Configuration | Hardware/Software | Software | Hardware/Software |

| Applications | R&D, Validation | Software Development | R&D, Testing, Development |

5. Choosing the Right OBD2 Emulator

Selecting the right OBD2 emulator requires careful consideration of your specific needs and applications. Factors such as the type of testing you’ll be performing, the protocols you need to support, and your budget will all play a role in your decision.

5.1. Determine Your Needs

The first step in choosing an OBD2 emulator is to determine your specific needs. Ask yourself the following questions:

- What type of testing will you be performing? Are you developing software, diagnosing vehicle issues, or conducting research and development?

- What protocols do you need to support? Do you need to support CAN, KWP2000, ISO9141, or J1850?

- What level of accuracy do you require? Do you need a high degree of realism, or is a basic simulation sufficient?

- What is your budget? How much are you willing to spend on an OBD2 emulator?

5.2. Consider Key Features

Once you have determined your needs, consider the key features that are important to you. Some features to consider include:

- Protocol Support: Ensure that the emulator supports the OBD-II protocols that you need to test.

- PID Emulation: Check that the emulator can simulate the PIDs that you need to monitor.

- DTC Generation: Verify that the emulator can generate the DTCs that you need to test.

- Connectivity: Consider the connectivity options that are available, such as USB, serial UART, or Bluetooth.

- Ease of Use: Look for an emulator that is easy to set up and use, with a user-friendly interface.

- Accuracy: Choose an emulator that provides the level of accuracy that you require.

5.3. Read Reviews and Compare Products

Before making a final decision, read reviews and compare products from different manufacturers. Look for reviews from other users who have used the emulator for similar applications. Compare the features, specifications, and prices of different emulators to find the best option for your needs.

5.4. Consider the Software Interface

The software interface of an OBD2 emulator is a crucial aspect to consider, as it directly impacts the ease of use and overall efficiency of the device. A well-designed software interface can simplify complex tasks and provide a seamless user experience.

- User-Friendliness: Look for an emulator with an intuitive and user-friendly software interface. The interface should be easy to navigate, with clear labels and well-organized menus.

- Configuration Options: The software interface should provide a wide range of configuration options, allowing you to customize the emulator’s behavior to meet your specific needs.

- Data Visualization: The interface should offer tools for visualizing simulated data, such as graphs, charts, and tables. This can help you to quickly identify trends and patterns in the data.

- Logging and Reporting: The software interface should allow you to log data and generate reports. This can be useful for documenting your testing and analysis.

- Compatibility: Ensure that the software interface is compatible with your operating system and hardware.

5.5. Check for Updates and Support

Before purchasing an OBD2 emulator, check to see if the manufacturer provides regular updates and support. Regular updates can ensure that the emulator remains compatible with the latest vehicles and diagnostic tools. Good support can help you to resolve any issues that you may encounter while using the emulator.

6. Setting Up Your OBD2 Emulator

Setting up an OBD2 emulator involves several steps to ensure it functions correctly and communicates effectively with diagnostic tools or software. The specific steps may vary depending on the emulator type (hardware, software, or hybrid) and the manufacturer’s instructions.

6.1. Hardware Setup

-

Unboxing and Inspection:

- Carefully unpack the OBD2 emulator and inspect all components for any physical damage.

- Verify that all necessary cables, adapters, and accessories are included.

-

Power Connection:

- Connect the emulator to a power source using the provided power adapter.

- Ensure the power adapter is compatible with the emulator’s voltage and current requirements.

-

OBD-II Port Connection:

- Locate the OBD-II port on your testing platform (e.g., a bench testing setup or a vehicle).

- Plug the emulator into the OBD-II port, ensuring a secure and stable connection.

6.2. Software Installation

-

Driver Installation:

- Insert the provided installation media (CD, USB drive) or download the latest drivers from the manufacturer’s website.

- Run the installer and follow the on-screen instructions to install the drivers.

- Ensure that the drivers are compatible with your operating system (e.g., Windows, macOS, Linux).

-

Software Installation:

- Install the emulator’s control software using the provided installation media or by downloading it from the manufacturer’s website.

- Follow the on-screen instructions to complete the installation process.

- Ensure that the software is compatible with your operating system and hardware.

6.3. Configuration

-

Device Recognition:

- Launch the emulator’s control software.

- Verify that the software recognizes the connected emulator.

- If the device is not recognized, check the connections, power supply, and driver installation.

-

Protocol Selection:

- Select the appropriate OBD-II protocol from the software’s configuration menu.

- Ensure that the selected protocol matches the protocol used by the vehicle or system you are testing.

-

PID and DTC Configuration:

- Configure the PIDs and DTCs that you want to simulate.

- Set the desired values for the PIDs and enable or disable the DTCs as needed.

6.4. Testing the Setup

-

Connect Diagnostic Tool:

- Connect a diagnostic tool or software application to the OBD-II port of the emulator.

-

Verify Communication:

- Use the diagnostic tool to send a request to the emulator.

- Verify that the emulator responds with the configured data.

-

Monitor Data:

- Monitor the data displayed by the diagnostic tool to ensure that it matches the configured values.

-

Troubleshooting:

- If you encounter any issues, check the connections, power supply, driver installation, software configuration, and communication settings.

- Refer to the emulator’s documentation or contact the manufacturer’s support team for assistance.

Freematics_Emulator_GUI_OBD_PIDs

Freematics_Emulator_GUI_OBD_PIDs

7. Advanced Techniques with OBD2 Emulators

OBD2 emulators can be used for more than just basic testing and simulation. With advanced techniques, you can leverage their capabilities for complex diagnostics, custom applications, and in-depth vehicle analysis.

7.1. Custom PID Creation and Configuration

Most OBD2 emulators allow users to create and configure custom PIDs (Parameter IDs) beyond the standard set. This is particularly useful for simulating proprietary vehicle data or testing specialized diagnostic tools.

- Identifying Custom PIDs:

- Research the specific vehicle or system you are emulating to identify any custom PIDs used.

- Consult vehicle manufacturer documentation or reverse-engineer the communication protocols to discover undocumented PIDs.

- Configuring Custom PIDs:

- Use the emulator’s software interface to define new PIDs, specifying their IDs, data types, and scaling factors.

- Assign simulated values to the custom PIDs, either manually or through automated scripts.

- Testing and Validation:

- Use diagnostic tools or custom software to query the custom PIDs and verify that the emulator returns the expected values.

- Monitor the behavior of the simulated system to ensure that the custom PIDs are functioning correctly.

7.2. Simulating Complex Vehicle Conditions

OBD2 emulators can be used to simulate a wide range of complex vehicle conditions, such as engine malfunctions, sensor failures, and communication errors. This allows developers and technicians to test their software and hardware under realistic scenarios without risking damage to a physical vehicle.

- Engine Malfunctions:

- Simulate engine misfires, lean or rich conditions, and other common engine problems by manipulating the values of relevant PIDs.

- Trigger diagnostic trouble codes (DTCs) associated with these malfunctions to test the diagnostic capabilities of your software.

- Sensor Failures:

- Emulate sensor failures by setting the values of sensor-related PIDs to invalid or out-of-range values.

- Test how your software responds to these failures and whether it can accurately diagnose the underlying issue.

- Communication Errors:

- Simulate communication errors by introducing delays, corrupting data packets, or dropping messages altogether.

- Evaluate the robustness of your software in the face of these errors and its ability to recover gracefully.

7.3. Integrating with Hardware-in-the-Loop (HIL) Systems

OBD2 emulators can be integrated with Hardware-in-the-Loop (HIL) systems to create a comprehensive testing environment for automotive ECUs (Electronic Control Units). HIL systems simulate the behavior of a vehicle’s electrical and mechanical components, allowing developers to test ECUs in a realistic and controlled environment.

- Connecting the Emulator:

- Connect the OBD2 emulator to the HIL system’s communication interface.

- Configure the HIL system to communicate with the emulator using the appropriate OBD-II protocol.

- Simulating Vehicle Dynamics:

- Use the HIL system to simulate the vehicle’s dynamics, such as speed, acceleration, and braking.

- Map these dynamics to the emulator’s PIDs to create a realistic driving experience.

- Testing ECU Behavior:

- Monitor the behavior of the ECU under various simulated driving conditions.

- Verify that the ECU responds correctly to changes in vehicle dynamics and diagnostic requests.

7.4. Automating Testing Procedures

OBD2 emulators can be automated to perform repetitive testing procedures, such as regression testing and compliance testing. This can save time and reduce the risk of human error.

- Scripting Languages:

- Use scripting languages such as Python or Perl to automate the interaction with the emulator.

- Write scripts to send commands, receive responses, and analyze the data.

- Testing Frameworks:

- Integrate the emulator with testing frameworks such as JUnit or TestNG to create automated test suites.

- Use these frameworks to run tests, generate reports, and track the results.

- Continuous Integration:

- Incorporate the automated tests into your continuous integration (CI) pipeline.

- Run the tests automatically whenever code changes are made to ensure that the software remains stable and reliable.

8. Common Issues and Troubleshooting

While OBD2 emulators are valuable tools, users may encounter certain issues during setup or operation. Troubleshooting these problems efficiently can minimize downtime and ensure accurate results.

8.1. Connectivity Problems

One of the most common issues is establishing a stable connection between the emulator and the diagnostic tool or software.

- Incorrect Protocol Selection: Ensure the correct OBD-II protocol (CAN, KWP2000, ISO9141, J1850) is selected in both the emulator software and the diagnostic tool. Mismatched protocols will prevent communication.

- Faulty Cables: Check the USB or serial cables for damage. Try using different cables to rule out a hardware issue.

- Driver Issues: Verify that the correct drivers for the emulator are installed and up-to-date. Reinstalling the drivers may resolve compatibility problems.

- Port Conflicts: Ensure that the COM port selected for serial communication is not being used by another application.

- Power Supply: Confirm that the emulator is receiving adequate power. Use the recommended power adapter and check the voltage output.

8.2. Data Inaccuracy

Inaccurate data simulation can lead to incorrect test results and unreliable diagnostics.

- Incorrect PID Configuration: Double-check the PID configuration settings in the emulator software. Ensure that the data types, scaling factors, and units are correctly defined.

- Outdated Firmware: Update the emulator’s firmware to the latest version. Firmware updates often include bug fixes and improved data simulation algorithms.

- Sensor Calibration: Calibrate the simulated sensors in the emulator software to match the expected values.

- Protocol Limitations: Be aware of the limitations of the OBD-II protocol being used. Some PIDs may not be supported or may provide limited data.

8.3. Software Compatibility

Compatibility issues between the emulator software and the operating system or diagnostic tools can cause malfunctions.

- Operating System Requirements: Verify that the emulator software is compatible with your operating system (Windows, macOS, Linux). Run the software in compatibility mode if necessary.

- Software Updates: Keep the emulator software and diagnostic tools updated to the latest versions.

- Firewall and Antivirus: Temporarily disable firewalls and antivirus software to rule out interference with the communication between the emulator and diagnostic tools.

- Administrative Privileges: Run the emulator software with administrative privileges to ensure it has access to all necessary system resources.

8.4. Emulator Freezing or Crashing

- Overloading the Emulator: Avoid sending too many requests or commands to the emulator simultaneously.

- Resource Constraints: Close unnecessary applications to free up system resources.

- Software Bugs: Report any software bugs or crashes to the emulator manufacturer for investigation and resolution.

- Hardware Malfunctions: If the emulator continues to freeze or crash, it may indicate a hardware malfunction. Contact the manufacturer for repair or replacement.

8.5. Error Messages

- Read the Error Message Carefully: Error messages often provide valuable clues about the nature and cause of the problem.

- Consult the Documentation: Refer to the emulator’s documentation or online resources for troubleshooting information related to the specific error message.

- Search Online Forums: Search online forums and communities for solutions to common problems and error messages.

- Contact Technical Support: If you are unable to resolve the issue, contact the emulator manufacturer’s technical support team for assistance.

9. Real-World Applications of OBD2 Emulators

OBD2 emulators are used in various real-world scenarios, providing significant benefits in automotive development, diagnostics, and training.

9.1. Automotive Software Development

OBD2 emulators play a crucial role in automotive software development, allowing developers to test and validate their code without requiring access to physical vehicles. This reduces development costs and accelerates the software development lifecycle.

- Testing Diagnostic Software: Developers can use OBD2 emulators to test diagnostic software, ensuring that it can accurately read and interpret OBD-II data from a variety of simulated vehicles.

- Validating Firmware Updates: Emulators can be used to validate firmware updates for ECUs, verifying that the updates do not introduce any new issues or compatibility problems.

- Developing Mobile Apps: Developers can create mobile apps that interact with OBD-II data, using emulators to simulate the data and test the app’s functionality.

9.2. Diagnostic Tool Validation

Diagnostic tool manufacturers use OBD2 emulators to validate the accuracy and reliability of their tools. This ensures that the tools can correctly diagnose vehicle problems in real-world scenarios.

- Protocol Compliance Testing: Emulators can be used to test whether diagnostic tools comply with OBD-II standards and protocols.

- PID Support Verification: Manufacturers can verify that their tools support all required PIDs and can accurately read the data.

- DTC Interpretation Testing: Emulators allow testing of the diagnostic tools’ ability to correctly interpret DTCs and provide accurate diagnostic information.

9.3. Automotive Training and Education

OBD2 emulators are valuable tools for automotive training and education, providing a safe and controlled environment for students to learn about vehicle diagnostics and repair.

- Hands-On Training: Students can use emulators to gain hands-on experience with OBD-II systems, learning how to read data, interpret DTCs, and diagnose vehicle problems.

- Simulated Fault Injection: Instructors can use emulators to inject simulated faults into the system, challenging students to diagnose and repair the problems.

- Cost-Effective Training: Emulators reduce the need for physical vehicles, making automotive training more cost-effective and accessible.

9.4. Research and Development

Researchers and engineers use OBD2 emulators to conduct research and development on new automotive technologies.

- Vehicle Performance Analysis: Emulators can be used to simulate different driving conditions and analyze vehicle performance under those conditions.

- Fuel Efficiency Studies: Researchers can use emulators to study fuel efficiency and emissions, testing new technologies and strategies for reducing fuel consumption and pollution.

- Security Vulnerability Testing: Emulators can be used to test the security of vehicle systems, identifying vulnerabilities that could be exploited by hackers.

9.5. Vehicle Reprogramming and Tuning

OBD2 emulators can also be applied in vehicle reprogramming and tuning, providing a controlled environment for modifying ECU parameters.

- ECU Flashing: Tuners can use emulators to test new ECU maps and calibrations before flashing them onto a physical vehicle.

- Performance Tuning: Emulators allow users to experiment with different tuning parameters, such as fuel injection timing and ignition advance, to optimize vehicle performance.

- Emissions Testing: Emulators can be used to test the emissions impact of different tuning settings, ensuring that the vehicle remains compliant with emissions regulations.

10. Future Trends in OBD2 Emulation

The field of OBD2 emulation is continuously evolving, driven by advancements in automotive technology and the increasing demand for sophisticated diagnostic and testing tools.

10.1. Enhanced Protocol Support

- CAN FD (Flexible Data-Rate): Future OBD2 emulators will likely support CAN FD, a faster and more efficient version of the CAN protocol used in modern vehicles.

- Ethernet: As Ethernet becomes more prevalent in automotive networks, emulators will need to support Ethernet-based diagnostic protocols.

- Wireless Communication: Emulators will increasingly support wireless communication protocols such as Wi-Fi and Bluetooth for remote access and control.

10.2. Advanced Simulation Capabilities

- Artificial Intelligence (AI): AI-powered emulators will be able to learn from real-world data and simulate more realistic vehicle behavior.

- Machine Learning (ML): ML algorithms will be used to predict vehicle performance and diagnose problems based on historical data.

- Virtual Reality (VR): VR technology will be integrated into emulators to provide immersive training and diagnostic experiences.

10.3. Cloud Integration

- Remote Access: Cloud-based emulators will allow users to access and control the emulator from anywhere in the world.

- Data Sharing: Cloud integration will enable data sharing and collaboration among developers, technicians, and researchers.

- Software Updates: Cloud-based emulators will receive automatic software updates and bug fixes.

10.4. Increased Automation

- Automated Testing: Emulators will be able to automatically perform testing procedures, reducing the need for manual intervention.

- Regression Testing: Automated regression testing will ensure that software updates do not introduce new issues or compatibility problems.

- Compliance Testing: Emulators will be able to automatically verify that vehicle systems comply with regulatory standards.

10.5. Integration with Autonomous Vehicle Technologies

- Sensor Simulation: Emulators will be used to simulate the sensors used in autonomous vehicles, such as lidar, radar, and cameras.

- Scenario Testing: Emulators will allow developers to test autonomous vehicle software in a variety of simulated scenarios.

- Safety Validation: Emulators will be used to validate the safety of autonomous vehicle systems, ensuring that they can handle a wide range of real-world situations.

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are dedicated to keeping you informed about the latest advancements in OBD2 emulation technology, providing you with the knowledge and tools you need to stay ahead in the automotive industry.

Navigating the complexities of Mercedes-Benz diagnostics and maintenance can be challenging, but you don’t have to do it alone. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer expert guidance, comprehensive resources, and cutting-edge tools to empower you.

FAQ: OBD2 Emulators

1. What exactly is an OBD2 emulator?

An OBD2 emulator is a device that simulates the functions of a vehicle’s On-Board Diagnostics (OBD) system, allowing users to test diagnostic tools, develop software, and perform vehicle simulations without needing a physical car.

2. What are the primary uses of an OBD2 emulator?

OBD2 emulators are primarily used for software development,