The Obd2 O2 Sensor Test is crucial for diagnosing engine problems related to air-fuel mixture and emissions, and with MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you gain access to expert insights and tools for accurate diagnostics. By utilizing an OBD2 scanner, you can effectively monitor oxygen levels, diagnose faulty sensors, and optimize your engine’s performance. Explore advanced troubleshooting techniques with our LSI keyword-rich resources for peak automotive care.

Contents

- 1. Understanding the OBD2 O2 Sensor Test

- 1.1 What are Oxygen Sensors?

- 1.2 Why is the O2 Sensor Test Important?

- 1.3 Types of Oxygen Sensors

- 1.4 OBD2 Scanner Overview

- 2. Preparing for the OBD2 O2 Sensor Test

- 2.1 Gathering Necessary Tools

- 2.2 Understanding OBD2 Port Location

- 2.3 Basic Vehicle Inspection

- 2.4 Ensuring Vehicle Readiness

- 3. Performing the OBD2 O2 Sensor Test: A Step-by-Step Guide

- 3.1 Connecting the OBD2 Scanner

- 3.2 Navigating the Scanner Menu

- 3.3 Reading Live O2 Sensor Data

- 3.4 Interpreting the Results

- 4. Common OBD2 Trouble Codes Related to O2 Sensors

- 4.1 P0130: O2 Sensor Circuit Malfunction (Bank 1, Sensor 1)

- 4.2 P0131: O2 Sensor Circuit Low Voltage (Bank 1, Sensor 1)

- 4.3 P0132: O2 Sensor Circuit High Voltage (Bank 1, Sensor 1)

- 4.4 P0135: O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 1)

- 4.5 P0171: System Too Lean (Bank 1)

- 4.6 P0174: System Too Lean (Bank 2)

- 5. Troubleshooting O2 Sensor Issues

- 5.1 Verifying the Code

- 5.2 Inspecting the Sensor and Wiring

- 5.3 Testing the Sensor

- 5.4 Checking for Exhaust Leaks

- 5.5 Addressing Other Potential Issues

- 6. Maintaining Your Mercedes-Benz O2 Sensors

- 6.1 Regular Inspections

- 6.2 Cleaning O2 Sensors (If Applicable)

- 6.3 Replacing O2 Sensors

- 6.4 Preventing Contamination

- 7. Benefits of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for O2 Sensor Diagnostics

- 8. Advanced Diagnostic Techniques

- 8.1 Using an Oscilloscope

- 8.2 Performing a Dynamic Test

- 8.3 Analyzing Fuel Trim Data

- 8.4 Using a Scan Tool with Advanced Functions

- 9. Case Studies: Real-World O2 Sensor Diagnostics

- 9.1 Case Study 1: P0131 Code on a Mercedes-Benz C-Class

- 9.2 Case Study 2: P0135 Code on a Mercedes-Benz E-Class

- 9.3 Case Study 3: Intermittent P0171 Code on a Mercedes-Benz S-Class

- 10. Frequently Asked Questions (FAQs) About OBD2 O2 Sensor Tests

- 10.1 What does an OBD2 O2 sensor test do?

- 10.2 How do I read O2 sensor data on a scan tool?

- 10.3 What are signs of a bad O2 sensor?

- 10.4 How do you read an O2 sensor with a multimeter?

- 10.5 Can a bad O2 sensor cause a misfire?

- 10.6 How often should I replace my O2 sensors?

- 10.7 Can I drive with a bad O2 sensor?

- 10.8 How much does it cost to replace an O2 sensor?

- 10.9 What is the difference between upstream and downstream O2 sensors?

- 10.10 How can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN help with O2 sensor diagnostics?

1. Understanding the OBD2 O2 Sensor Test

An OBD2 O2 sensor test is a diagnostic procedure that evaluates the performance of your vehicle’s oxygen sensors using an OBD2 scanner. These sensors play a crucial role in monitoring the amount of oxygen in the exhaust gases, which helps the engine control unit (ECU) regulate the air-fuel mixture. Proper functioning of O2 sensors ensures optimal engine performance, fuel efficiency, and reduced emissions.

1.1 What are Oxygen Sensors?

Oxygen sensors, often referred to as O2 sensors, are components in your car’s exhaust system that measure the amount of oxygen in the exhaust gases. The data from these sensors is sent to the engine control unit (ECU), which uses it to adjust the air-fuel mixture. This adjustment is essential for efficient combustion and reducing harmful emissions. According to a study by the U.S. Environmental Protection Agency (EPA), properly functioning O2 sensors can improve fuel efficiency by up to 40%.

1.2 Why is the O2 Sensor Test Important?

The O2 sensor test is important for several reasons:

- Fuel Efficiency: Faulty O2 sensors can lead to an incorrect air-fuel mixture, reducing fuel economy.

- Emission Control: Malfunctioning sensors can cause higher emissions, leading to failed emissions tests.

- Engine Performance: Incorrect data from O2 sensors can result in poor engine performance, including rough idling and hesitation.

- Preventing Damage: Addressing O2 sensor issues early can prevent damage to other components, such as the catalytic converter.

1.3 Types of Oxygen Sensors

There are primarily two types of oxygen sensors used in modern vehicles:

- Upstream Sensors: Located before the catalytic converter, these sensors directly measure the oxygen content in the exhaust gases coming from the engine. They provide critical data for adjusting the air-fuel mixture.

- Downstream Sensors: Positioned after the catalytic converter, these sensors monitor the efficiency of the converter by measuring the oxygen content after the exhaust gases have passed through it.

Upstream Oxygen Sensor

Upstream Oxygen Sensor

1.4 OBD2 Scanner Overview

An OBD2 scanner is a diagnostic tool used to access data from your vehicle’s onboard computer system. It can read diagnostic trouble codes (DTCs), monitor live sensor data, and perform various tests, including the O2 sensor test. According to a report by AAA, using an OBD2 scanner can help car owners save an average of $100 on diagnostic fees.

2. Preparing for the OBD2 O2 Sensor Test

Before conducting an OBD2 O2 sensor test, it’s important to gather the necessary tools and information. This preparation ensures that you can perform the test accurately and interpret the results effectively.

2.1 Gathering Necessary Tools

To perform an OBD2 O2 sensor test, you will need the following tools:

- OBD2 Scanner: A reliable OBD2 scanner is essential for accessing the vehicle’s diagnostic data. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a range of high-quality scanners compatible with Mercedes-Benz vehicles.

- Vehicle Repair Manual: A repair manual specific to your vehicle model can provide valuable information about sensor locations, wiring diagrams, and troubleshooting procedures.

- Multimeter (Optional): A multimeter can be used to check the sensor’s voltage and resistance, providing additional insights into its condition.

2.2 Understanding OBD2 Port Location

The OBD2 port is typically located under the dashboard on the driver’s side. Its exact location can vary depending on the vehicle model, but it is usually within easy reach. Consult your vehicle’s repair manual if you are unsure of its location.

2.3 Basic Vehicle Inspection

Before starting the O2 sensor test, perform a basic inspection of your vehicle. Check for any obvious issues, such as:

- Loose or damaged wiring around the O2 sensors

- Exhaust leaks near the sensors

- Contamination on the sensor elements

Addressing these issues before the test can prevent inaccurate results.

2.4 Ensuring Vehicle Readiness

Ensure that your vehicle is in a suitable condition for testing. This includes:

- The engine should be warmed up to its normal operating temperature.

- The vehicle should be parked in a safe and well-ventilated area.

- Turn off any unnecessary electrical loads, such as headlights and air conditioning.

3. Performing the OBD2 O2 Sensor Test: A Step-by-Step Guide

Once you have prepared your tools and vehicle, you can proceed with the OBD2 O2 sensor test. Follow these steps to perform the test accurately and effectively.

3.1 Connecting the OBD2 Scanner

- Locate the OBD2 Port: Find the OBD2 port under the dashboard on the driver’s side.

- Plug in the Scanner: Connect the OBD2 scanner to the port, ensuring a secure connection.

- Turn on the Ignition: Turn the ignition key to the “ON” position without starting the engine.

- Power on the Scanner: Turn on the OBD2 scanner and wait for it to establish a connection with the vehicle’s computer.

3.2 Navigating the Scanner Menu

- Select Vehicle Information: Enter your vehicle’s make, model, and year into the scanner.

- Choose Diagnostic Mode: Select the diagnostic mode from the main menu.

- Access Live Data: Navigate to the live data or sensor data section.

- Select O2 Sensor Data: Choose the option to view O2 sensor data.

3.3 Reading Live O2 Sensor Data

- Monitor Voltage Readings: Observe the voltage readings from the O2 sensors. A healthy sensor should show fluctuating voltage between 0.1V and 0.9V.

- Check Response Time: Note how quickly the sensor responds to changes in engine conditions. A slow response time can indicate a faulty sensor.

- Evaluate Sensor Behavior: Watch for any unusual patterns, such as flatlining, erratic readings, or lack of response.

3.4 Interpreting the Results

- Normal Readings: Fluctuating voltage between 0.1V and 0.9V indicates that the sensor is functioning correctly.

- High Voltage: A consistently high voltage reading (close to 0.9V) may indicate a rich fuel mixture or a faulty sensor.

- Low Voltage: A consistently low voltage reading (close to 0.1V) may indicate a lean fuel mixture or a faulty sensor.

- Slow Response: A slow response time suggests that the sensor is aging or contaminated and may need to be replaced.

4. Common OBD2 Trouble Codes Related to O2 Sensors

Understanding the diagnostic trouble codes (DTCs) related to O2 sensors is essential for accurate diagnosis and repair. Here are some common codes and their meanings:

4.1 P0130: O2 Sensor Circuit Malfunction (Bank 1, Sensor 1)

This code indicates a problem with the O2 sensor circuit in Bank 1, Sensor 1. Potential causes include:

- Faulty sensor

- Wiring issues

- Connector problems

- ECU malfunction

4.2 P0131: O2 Sensor Circuit Low Voltage (Bank 1, Sensor 1)

This code indicates that the O2 sensor voltage is lower than expected. Possible causes include:

- Lean fuel mixture

- Vacuum leaks

- Faulty sensor

- Wiring issues

4.3 P0132: O2 Sensor Circuit High Voltage (Bank 1, Sensor 1)

This code indicates that the O2 sensor voltage is higher than expected. Possible causes include:

- Rich fuel mixture

- Faulty sensor

- Wiring issues

- High fuel pressure

4.4 P0135: O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 1)

This code indicates a problem with the O2 sensor heater circuit. Potential causes include:

- Faulty heater element

- Wiring issues

- Blown fuse

- ECU malfunction

4.5 P0171: System Too Lean (Bank 1)

This code indicates that the engine is running too lean on Bank 1. Possible causes include:

- Vacuum leaks

- Faulty O2 sensor

- Low fuel pressure

- Clogged fuel filter

4.6 P0174: System Too Lean (Bank 2)

This code indicates that the engine is running too lean on Bank 2. Possible causes are similar to P0171 but apply to Bank 2.

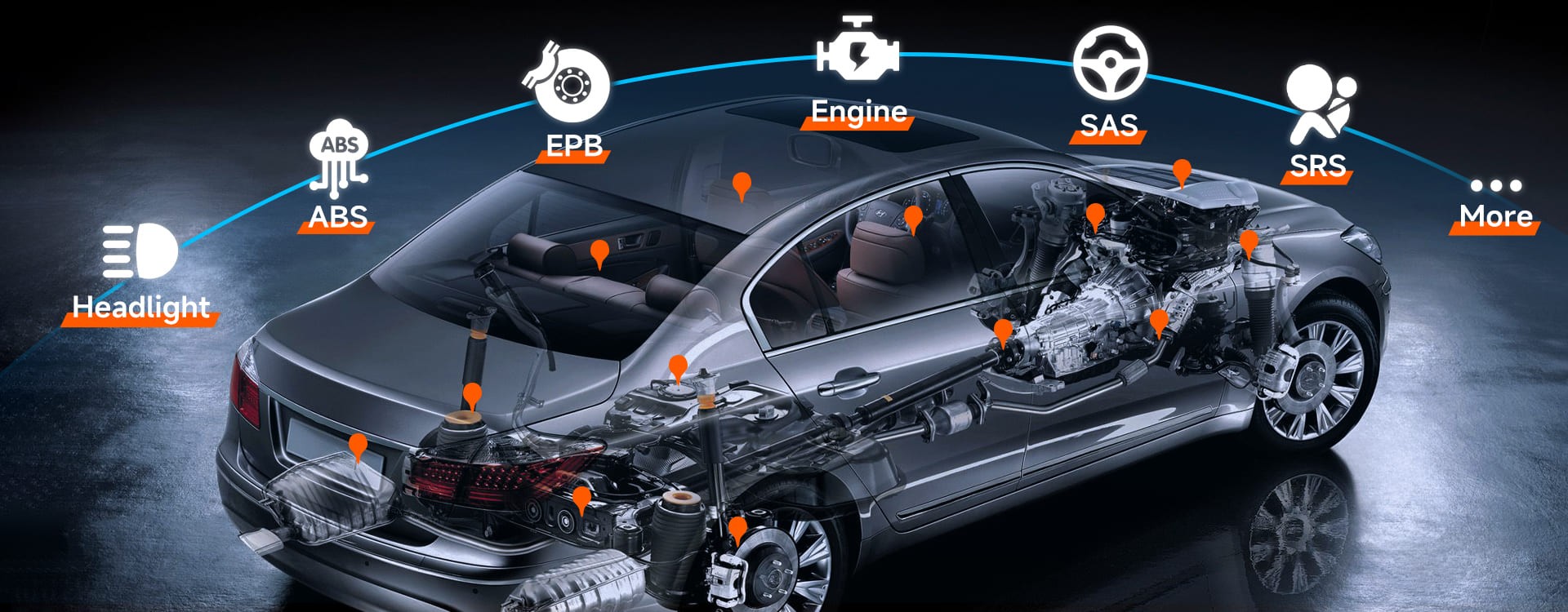

Systems Diagnostic Car Scanner

Systems Diagnostic Car Scanner

5. Troubleshooting O2 Sensor Issues

When you encounter O2 sensor-related trouble codes, it’s important to follow a systematic troubleshooting process to identify and resolve the underlying issue.

5.1 Verifying the Code

- Read the Code: Use an OBD2 scanner to read the trouble code and verify its accuracy.

- Record the Code: Document the code and any related freeze frame data.

- Clear the Code: Clear the code and test drive the vehicle to see if it returns.

5.2 Inspecting the Sensor and Wiring

- Visual Inspection: Check the sensor for any signs of damage, such as cracks, corrosion, or contamination.

- Wiring Inspection: Inspect the wiring harness and connectors for any loose, damaged, or corroded wires.

- Connector Check: Ensure that the connectors are securely attached and free from corrosion.

5.3 Testing the Sensor

- Voltage Test: Use a multimeter to measure the sensor’s voltage output. A healthy sensor should show fluctuating voltage between 0.1V and 0.9V.

- Resistance Test: Measure the sensor’s resistance to check the heater circuit’s functionality. Refer to the vehicle’s repair manual for the correct resistance values.

- Ground Test: Verify that the sensor has a good ground connection.

5.4 Checking for Exhaust Leaks

- Visual Inspection: Look for any signs of exhaust leaks near the O2 sensors, such as soot or corrosion.

- Listening Test: Listen for any hissing or whistling sounds that may indicate an exhaust leak.

- Smoke Test: Perform a smoke test to identify any hidden exhaust leaks.

5.5 Addressing Other Potential Issues

- Vacuum Leaks: Check for vacuum leaks using a vacuum gauge or smoke test.

- Fuel Pressure: Verify that the fuel pressure is within the specified range.

- Fuel Injectors: Inspect the fuel injectors for proper operation and spray pattern.

- Air Filter: Check the air filter to ensure it is clean and not restricting airflow.

6. Maintaining Your Mercedes-Benz O2 Sensors

Proper maintenance of your Mercedes-Benz O2 sensors is essential for ensuring optimal engine performance, fuel efficiency, and emission control. Regular checks and timely replacements can prevent costly repairs and keep your vehicle running smoothly.

6.1 Regular Inspections

- Visual Inspections: Periodically inspect the O2 sensors and their wiring for any signs of damage or corrosion.

- OBD2 Scans: Use an OBD2 scanner to check for any pending or active trouble codes related to the O2 sensors.

- Performance Monitoring: Monitor your vehicle’s fuel economy and engine performance for any signs of O2 sensor issues.

6.2 Cleaning O2 Sensors (If Applicable)

In some cases, O2 sensors can be cleaned to remove contaminants and restore their performance. However, this is not always recommended, as improper cleaning can damage the sensor. Consult your vehicle’s repair manual or a professional mechanic before attempting to clean your O2 sensors.

6.3 Replacing O2 Sensors

- Recommended Intervals: Replace the O2 sensors at the manufacturer’s recommended intervals. Typically, upstream sensors should be replaced every 60,000 to 100,000 miles, while downstream sensors can last longer.

- Quality Parts: Use high-quality replacement O2 sensors that are specifically designed for your Mercedes-Benz model. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a wide selection of OEM and aftermarket O2 sensors.

- Professional Installation: If you are not comfortable replacing the O2 sensors yourself, seek professional assistance from a qualified mechanic.

6.4 Preventing Contamination

- Use Quality Fuel: Use high-quality fuel that meets the manufacturer’s specifications.

- Address Oil Leaks: Repair any oil leaks promptly to prevent oil from contaminating the O2 sensors.

- Avoid Additives: Avoid using fuel additives that can damage the O2 sensors.

7. Benefits of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for O2 Sensor Diagnostics

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides numerous benefits for diagnosing and maintaining your Mercedes-Benz O2 sensors:

- Expert Guidance: Access to expert guidance and troubleshooting tips from experienced Mercedes-Benz technicians.

- High-Quality Tools: A wide selection of high-quality OBD2 scanners and diagnostic tools specifically designed for Mercedes-Benz vehicles.

- Comprehensive Information: Comprehensive information on O2 sensor function, troubleshooting, and replacement procedures.

- Genuine Parts: Access to genuine Mercedes-Benz O2 sensors and replacement parts.

- Cost Savings: Save money on diagnostic fees and repairs by performing O2 sensor tests and replacements yourself.

8. Advanced Diagnostic Techniques

For more complex O2 sensor issues, advanced diagnostic techniques may be required. These techniques involve using specialized tools and procedures to pinpoint the root cause of the problem.

8.1 Using an Oscilloscope

An oscilloscope can be used to visualize the O2 sensor’s voltage waveform. This can provide valuable insights into the sensor’s response time and overall performance. A healthy sensor should exhibit a smooth, consistent waveform with rapid transitions between high and low voltage.

8.2 Performing a Dynamic Test

A dynamic test involves monitoring the O2 sensor’s response while varying the engine’s operating conditions. This can help identify issues that may not be apparent during a static test. For example, you can monitor the sensor’s response while accelerating, decelerating, or idling.

8.3 Analyzing Fuel Trim Data

Fuel trim data provides information about the ECU’s adjustments to the air-fuel mixture. By analyzing short-term and long-term fuel trim values, you can gain insights into the overall health of the engine and identify potential O2 sensor issues.

8.4 Using a Scan Tool with Advanced Functions

Some OBD2 scan tools offer advanced functions, such as O2 sensor testing, data logging, and graphing. These tools can provide more detailed information about the O2 sensor’s performance and help you diagnose complex issues more effectively.

9. Case Studies: Real-World O2 Sensor Diagnostics

To illustrate the practical application of OBD2 O2 sensor testing, here are a few case studies based on real-world scenarios:

9.1 Case Study 1: P0131 Code on a Mercedes-Benz C-Class

A Mercedes-Benz C-Class owner experienced a check engine light and a P0131 code (O2 Sensor Circuit Low Voltage, Bank 1, Sensor 1). Using an OBD2 scanner, the technician verified the code and monitored the O2 sensor’s live data. The sensor voltage was consistently low, indicating a lean fuel mixture or a faulty sensor.

After inspecting the engine, the technician discovered a vacuum leak in the intake manifold. Repairing the vacuum leak resolved the lean condition, and the O2 sensor voltage returned to normal. The check engine light was cleared, and the vehicle’s performance was restored.

9.2 Case Study 2: P0135 Code on a Mercedes-Benz E-Class

A Mercedes-Benz E-Class owner reported poor fuel economy and a check engine light. An OBD2 scan revealed a P0135 code (O2 Sensor Heater Circuit Malfunction, Bank 1, Sensor 1). The technician used a multimeter to test the O2 sensor heater circuit and found that the heater element was not functioning.

The O2 sensor was replaced with a new one, and the P0135 code was cleared. The vehicle’s fuel economy improved, and the check engine light remained off.

9.3 Case Study 3: Intermittent P0171 Code on a Mercedes-Benz S-Class

A Mercedes-Benz S-Class owner experienced an intermittent check engine light and a P0171 code (System Too Lean, Bank 1). The technician used an OBD2 scanner to monitor the O2 sensor’s live data and fuel trim values. The data showed that the engine was running lean under certain conditions, but the O2 sensor appeared to be functioning correctly.

After further investigation, the technician discovered a clogged fuel filter. Replacing the fuel filter resolved the lean condition, and the P0171 code no longer appeared.

10. Frequently Asked Questions (FAQs) About OBD2 O2 Sensor Tests

10.1 What does an OBD2 O2 sensor test do?

An OBD2 O2 sensor test evaluates the performance of your vehicle’s oxygen sensors, which monitor the amount of oxygen in the exhaust gases, helping the engine control unit (ECU) regulate the air-fuel mixture.

10.2 How do I read O2 sensor data on a scan tool?

To read O2 sensor data on a scan tool, connect the scanner to the OBD-II port, select the “O2 Sensor Test” or “Live Data” option, and monitor the voltage readings. A healthy sensor should show fluctuating voltage between 0.1V and 0.9V.

10.3 What are signs of a bad O2 sensor?

Signs of a bad O2 sensor include poor fuel economy, a rough idle, the check engine light coming on, and failed emissions tests. You might also notice engine misfires or hesitation during acceleration.

10.4 How do you read an O2 sensor with a multimeter?

To read an O2 sensor with a multimeter, set the multimeter to the DC voltage setting. Connect the probes to the sensor’s signal wire and ground, then start the engine. A functioning sensor should show a fluctuating voltage between 0.1V and 0.9V.

10.5 Can a bad O2 sensor cause a misfire?

Yes, a faulty O2 sensor can cause a misfire. If the sensor provides incorrect data to the engine control unit (ECU), it can disrupt the air-fuel mixture, leading to misfires.

10.6 How often should I replace my O2 sensors?

Upstream O2 sensors should typically be replaced every 60,000 to 100,000 miles, while downstream sensors can last longer. Consult your vehicle’s repair manual for specific recommendations.

10.7 Can I drive with a bad O2 sensor?

While it is possible to drive with a bad O2 sensor, it is not recommended. A faulty sensor can lead to poor fuel economy, increased emissions, and potential damage to other engine components.

10.8 How much does it cost to replace an O2 sensor?

The cost to replace an O2 sensor can vary depending on the vehicle model and the type of sensor. On average, the cost ranges from $100 to $300, including parts and labor.

10.9 What is the difference between upstream and downstream O2 sensors?

Upstream sensors are located before the catalytic converter and measure the oxygen content in the exhaust gases coming from the engine. Downstream sensors are positioned after the catalytic converter and monitor the efficiency of the converter.

10.10 How can MERCEDES-DIAGNOSTIC-TOOL.EDU.VN help with O2 sensor diagnostics?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers expert guidance, high-quality diagnostic tools, comprehensive information, and genuine parts to help you diagnose and maintain your Mercedes-Benz O2 sensors effectively, saving you time and money.

By understanding the OBD2 O2 sensor test and following the guidelines provided by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can ensure your Mercedes-Benz runs smoothly and efficiently.

Don’t let O2 sensor issues compromise your Mercedes-Benz’s performance. Contact us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert guidance, high-quality diagnostic tools, and genuine replacement parts. Reach out today via Whatsapp at +1 (641) 206-8880 or visit our location at 789 Oak Avenue, Miami, FL 33101, United States to ensure your vehicle runs at its best. Let us help you keep your Mercedes-Benz in top condition with our comprehensive diagnostic and maintenance solutions.