The Obd2 P0018 code indicates a timing misalignment between the crankshaft and camshaft on bank 2 sensor A, potentially leading to reduced engine performance or starting issues. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer comprehensive diagnostic solutions and expert guidance to resolve this issue efficiently. Discover the causes, symptoms, and effective repair strategies for the P0018 code. Explore in-depth troubleshooting techniques, component testing, and advanced diagnostic procedures to ensure your Mercedes operates at peak performance, and learn about camshaft position sensor and crankshaft position sensor.

Contents

- 1. Understanding the OBD2 P0018 Code

- 1.1. What is the P0018 Code?

- 1.2. What Does Bank 2 Sensor A Mean?

- 1.3. How Serious is the P0018 Code?

- 2. Common Symptoms of the P0018 Code

- 2.1. Malfunction Indicator Lamp (MIL) Illumination

- 2.2. Reduced Engine Performance

- 2.3. Engine Misfires

- 2.4. Difficult Starting

- 2.5. Poor Fuel Economy

- 2.6. Engine Noise

- 3. Potential Causes of the P0018 Code

- 3.1. Timing Chain or Belt Issues

- 3.1.1. Stretched Timing Chain

- 3.1.2. Skipped Tooth on Timing Belt

- 3.2. Timing Component Damage

- 3.2.1. Damaged Timing Chain Tensioner

- 3.2.2. Worn or Damaged Timing Gears or Sprockets

- 3.3. Sensor Problems

- 3.3.1. Faulty Crankshaft Position (CKP) Sensor

- 3.3.2. Faulty Camshaft Position (CMP) Sensor

- 3.4. Wiring and Connector Issues

- 3.4.1. Damaged Wiring Harness

- 3.4.2. Loose or Corroded Connectors

- 3.5. Tone Ring Problems

- 3.5.1. Damaged Tone Ring on Crankshaft

- 3.5.2. Damaged Tone Ring on Camshaft

- 3.6. Other Potential Causes

- 3.6.1. Improperly Torqued Crankshaft Balancer

- 3.6.2. Mis-built or Mis-timed Engine

- 3.6.3. CMP Actuator Solenoid Issues

- 4. Diagnostic Steps for the P0018 Code

- 4.1. Preliminary Checks

- 4.1.1. Visual Inspection

- 4.1.2. Scan for Other DTCs

- 4.2. Sensor Testing

- 4.2.1. CKP Sensor Testing

- 4.2.2. CMP Sensor Testing

- 4.3. Wiring and Connector Testing

- 4.3.1. Continuity Test

- 4.3.2. Voltage Test

- 4.4. Timing Component Inspection

- 4.4.1. Timing Chain/Belt Inspection

- 4.4.2. Tensioner Inspection

- 4.5. Advanced Diagnostics

- 4.5.1. Oscilloscope Testing

- 4.5.2. Crankshaft Endplay Check

- 4.6. Verifying the Repair

- 4.6.1. Clear DTCs

- 4.6.2. Test Drive

- 5. Repairing the P0018 Code

- 5.1. Replacing Faulty Sensors

- 5.1.1. Replacing CKP Sensor

- 5.1.2. Replacing CMP Sensor

- 5.2. Repairing Wiring and Connectors

- 5.2.1. Wiring Repair

- 5.2.2. Connector Replacement

- 5.3. Timing Component Replacement

- 5.3.1. Timing Chain/Belt Replacement

- 5.3.2. Tensioner Replacement

- 5.4. Tone Ring Repair/Replacement

- 5.4.1. Tone Ring Repair

- 5.4.2. Tone Ring Replacement

- 5.5. Additional Repairs

- 5.5.1. Crankshaft Balancer Replacement

- 5.5.2. CMP Actuator Solenoid Replacement

- 6. Preventative Maintenance for Avoiding the P0018 Code

- 6.1. Regular Oil Changes

- 6.2. Timing Chain/Belt Inspection

- 6.3. Sensor Maintenance

- 6.4. Tensioner Maintenance

- 6.5. Scheduled Maintenance

- 7. Tools and Equipment for Diagnosing and Repairing P0018

- 7.1. OBD2 Scanner

- 7.2. Multimeter

- 7.3. Oscilloscope

- 7.4. Timing Light

- 7.5. Socket Set and Wrenches

- 7.6. Torque Wrench

- 7.7. Wire Strippers and Crimpers

- 7.8. Diagnostic Software

- 8. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in Addressing P0018

- 8.1. Expert Diagnostic Services

- 8.2. High-Quality Repair Solutions

- 8.3. Advanced Diagnostic Tools and Equipment

- 8.4. Comprehensive Guides and Resources

- 8.5. Personalized Support and Consultation

- 9. Case Studies: Resolving P0018 in Mercedes Vehicles

- 9.1. Case Study 1: 2015 Mercedes-Benz C300

- 9.2. Case Study 2: 2012 Mercedes-Benz E350

- 9.3. Case Study 3: 2018 Mercedes-Benz GLC300

- 10. Frequently Asked Questions (FAQs) About the P0018 Code

- 10.1. What is the most common cause of the P0018 code?

- 10.2. Can I drive my car with the P0018 code?

- 10.3. How much does it cost to fix the P0018 code?

- 10.4. Can a bad CKP sensor cause the P0018 code?

- 10.5. Can a bad CMP sensor cause the P0018 code?

- 10.6. How do I test the CKP sensor?

- 10.7. How do I test the CMP sensor?

- 10.8. What tools do I need to diagnose the P0018 code?

- 10.9. How often should I replace the timing chain?

- 10.10. Where can I get help diagnosing and repairing the P0018 code?

- 11. Conclusion

1. Understanding the OBD2 P0018 Code

1.1. What is the P0018 Code?

The P0018 code, defined as “Crankshaft Position – Camshaft Position Correlation (Bank 2 Sensor A),” signals a discrepancy between the signals from the crankshaft position (CKP) sensor and the camshaft position (CMP) sensor on bank 2, sensor A. According to the Society of Automotive Engineers (SAE), this indicates that the Powertrain Control Module (PCM) has detected that the timing relationship between the crankshaft and camshaft is not within the specified parameters. This misalignment can affect engine timing, fuel delivery, and overall engine performance, potentially leading to driveability issues or even engine damage.

1.2. What Does Bank 2 Sensor A Mean?

Bank 2 refers to the side of the engine opposite cylinder #1 in a V-type engine configuration. Sensor A typically refers to the intake camshaft position sensor. For inline engines, this designation might differ, so consulting the vehicle’s service manual is essential. The PCM uses the signals from these sensors to synchronize fuel injection and ignition timing. A mismatch indicates a mechanical or electrical issue affecting the timing correlation.

1.3. How Serious is the P0018 Code?

The severity of the P0018 code ranges from moderate to severe. While the engine may still run, the misalignment can cause reduced performance, poor fuel economy, and potential engine damage over time. Addressing the issue promptly is crucial to prevent further complications. Neglecting the P0018 code can lead to catalytic converter damage and increased emissions, resulting in costly repairs.

2. Common Symptoms of the P0018 Code

Recognizing the symptoms associated with the P0018 code is crucial for prompt diagnosis and repair. Here are the typical signs that your vehicle might be experiencing this issue:

2.1. Malfunction Indicator Lamp (MIL) Illumination

The most obvious sign is the illumination of the Malfunction Indicator Lamp (MIL) on the dashboard. This indicates that the PCM has detected a fault and stored the P0018 code in its memory.

2.2. Reduced Engine Performance

A noticeable decrease in engine power, acceleration, and overall performance may occur. The engine may feel sluggish, especially during acceleration or when climbing hills.

2.3. Engine Misfires

The engine may experience misfires, leading to rough idling, hesitation, and stumbling. Misfires can also trigger additional diagnostic trouble codes (DTCs) related to engine performance.

2.4. Difficult Starting

The engine may crank for an extended period before starting, or it may not start at all. The timing misalignment can disrupt the proper sequence of fuel injection and ignition, making it difficult for the engine to ignite.

2.5. Poor Fuel Economy

A decrease in fuel efficiency may be observed due to the engine running less efficiently. The PCM may adjust fuel delivery in an attempt to compensate for the timing misalignment, leading to increased fuel consumption.

2.6. Engine Noise

Unusual noises, such as rattling or knocking sounds, may emanate from the engine compartment. These noises can be caused by the timing chain or belt slapping against the engine components due to misalignment or wear.

3. Potential Causes of the P0018 Code

Several factors can trigger the P0018 code. Understanding these causes can help streamline the diagnostic process and identify the root of the problem.

3.1. Timing Chain or Belt Issues

3.1.1. Stretched Timing Chain

Over time, the timing chain can stretch due to wear and tear. This elongation can alter the timing relationship between the crankshaft and camshaft, triggering the P0018 code.

3.1.2. Skipped Tooth on Timing Belt

A timing belt can skip a tooth due to wear, improper tension, or sudden engine load. This misalignment disrupts the synchronization between the crankshaft and camshaft, causing the P0018 code to set.

3.2. Timing Component Damage

3.2.1. Damaged Timing Chain Tensioner

The timing chain tensioner maintains proper tension on the timing chain. If the tensioner fails or is damaged, the chain can become loose, leading to timing misalignment and the P0018 code.

3.2.2. Worn or Damaged Timing Gears or Sprockets

Worn or damaged timing gears or sprockets can affect the timing accuracy. Teeth on the gears can wear down or break, causing the timing chain or belt to slip.

3.3. Sensor Problems

3.3.1. Faulty Crankshaft Position (CKP) Sensor

A malfunctioning CKP sensor can send inaccurate signals to the PCM, leading to a false P0018 code. The sensor may be damaged, contaminated, or experiencing electrical issues.

3.3.2. Faulty Camshaft Position (CMP) Sensor

Similarly, a faulty CMP sensor can provide incorrect data to the PCM, triggering the P0018 code. Issues such as internal failure, wiring problems, or contamination can affect the sensor’s performance.

3.4. Wiring and Connector Issues

3.4.1. Damaged Wiring Harness

Damaged, corroded, or frayed wiring to the CKP or CMP sensors can disrupt the signal flow, leading to the P0018 code.

3.4.2. Loose or Corroded Connectors

Loose or corroded connectors at the CKP or CMP sensors can cause intermittent or unreliable signals, triggering the P0018 code.

3.5. Tone Ring Problems

3.5.1. Damaged Tone Ring on Crankshaft

The tone ring on the crankshaft provides the signal for the CKP sensor. If the tone ring is damaged, bent, or misaligned, it can cause inaccurate readings and trigger the P0018 code.

3.5.2. Damaged Tone Ring on Camshaft

Similarly, the tone ring on the camshaft provides the signal for the CMP sensor. Damage to this tone ring can also lead to inaccurate readings and the P0018 code.

3.6. Other Potential Causes

3.6.1. Improperly Torqued Crankshaft Balancer

An improperly torqued crankshaft balancer can cause vibrations and misalignment, leading to timing issues and the P0018 code.

3.6.2. Mis-built or Mis-timed Engine

In rare cases, the P0018 code can result from an engine that was improperly assembled or timed during manufacturing or previous repair.

3.6.3. CMP Actuator Solenoid Issues

The CMP actuator solenoid controls the camshaft timing. If this solenoid is stuck open or in a position other than 0 degrees, it can cause timing misalignment and trigger the P0018 code.

4. Diagnostic Steps for the P0018 Code

Diagnosing the P0018 code requires a systematic approach to identify the root cause of the issue. Follow these steps to ensure accurate diagnosis and effective repair:

4.1. Preliminary Checks

4.1.1. Visual Inspection

Begin with a thorough visual inspection of the CKP and CMP sensors, wiring, and connectors. Look for signs of damage, corrosion, or loose connections. Repair or replace any damaged components.

4.1.2. Scan for Other DTCs

Use an OBD2 scanner to check for any other diagnostic trouble codes (DTCs) present in the PCM. Address any related codes first, as they may provide additional clues to the cause of the P0018 code. Common related codes include P0008, P0009, P0016, P0017, and P0019.

4.2. Sensor Testing

4.2.1. CKP Sensor Testing

Use a multimeter to test the CKP sensor for proper resistance and voltage. Compare the readings to the manufacturer’s specifications. If the sensor fails the test, replace it.

4.2.2. CMP Sensor Testing

Similarly, test the CMP sensor for proper resistance and voltage using a multimeter. Compare the readings to the manufacturer’s specifications. Replace the sensor if it fails the test.

4.3. Wiring and Connector Testing

4.3.1. Continuity Test

Perform a continuity test on the wiring between the CKP and CMP sensors and the PCM. Check for any breaks or shorts in the wiring. Repair or replace any damaged wiring.

4.3.2. Voltage Test

Check the voltage at the CKP and CMP sensor connectors to ensure they are receiving the correct voltage from the PCM. Refer to the vehicle’s wiring diagram for the proper voltage specifications.

4.4. Timing Component Inspection

4.4.1. Timing Chain/Belt Inspection

Inspect the timing chain or belt for signs of wear, stretching, or damage. Check the alignment of the timing marks on the crankshaft and camshaft sprockets to ensure they are properly aligned.

4.4.2. Tensioner Inspection

Check the timing chain tensioner for proper operation. Ensure that it is maintaining the correct tension on the timing chain. Replace the tensioner if it is worn or damaged.

4.5. Advanced Diagnostics

4.5.1. Oscilloscope Testing

Use an oscilloscope to analyze the waveforms of the CKP and CMP sensors. Compare the waveforms to known good patterns to identify any irregularities or anomalies.

4.5.2. Crankshaft Endplay Check

Check the crankshaft endplay to ensure it is within the manufacturer’s specifications. Excessive endplay can indicate worn crankshaft bearings or other engine damage.

4.6. Verifying the Repair

4.6.1. Clear DTCs

After completing the repairs, clear the P0018 code from the PCM using an OBD2 scanner.

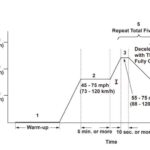

4.6.2. Test Drive

Perform a test drive to verify that the engine is running smoothly and that the P0018 code does not return. Monitor the engine performance and check for any unusual noises or symptoms.

5. Repairing the P0018 Code

The repair procedure for the P0018 code depends on the underlying cause. Here are some common repair strategies:

5.1. Replacing Faulty Sensors

5.1.1. Replacing CKP Sensor

If the CKP sensor is found to be faulty, replace it with a new, OEM-quality sensor. Ensure that the new sensor is properly installed and torqued to the manufacturer’s specifications.

5.1.2. Replacing CMP Sensor

Similarly, replace the CMP sensor if it is found to be faulty. Use a new, OEM-quality sensor and ensure proper installation and torque.

5.2. Repairing Wiring and Connectors

5.2.1. Wiring Repair

Repair any damaged or corroded wiring using proper splicing techniques and heat-shrink tubing. Ensure that the repaired wiring is properly insulated and protected from the elements.

5.2.2. Connector Replacement

Replace any damaged or corroded connectors with new, OEM-quality connectors. Ensure that the new connectors are properly installed and secured.

5.3. Timing Component Replacement

5.3.1. Timing Chain/Belt Replacement

If the timing chain or belt is stretched, worn, or damaged, replace it with a new, OEM-quality timing chain or belt kit. Follow the manufacturer’s instructions for proper installation and timing.

5.3.2. Tensioner Replacement

Replace the timing chain tensioner if it is worn, damaged, or not functioning properly. Use a new, OEM-quality tensioner and ensure proper installation and adjustment.

5.4. Tone Ring Repair/Replacement

5.4.1. Tone Ring Repair

If the tone ring is slightly damaged or misaligned, it may be possible to repair it. However, if the damage is severe, it is best to replace the tone ring.

5.4.2. Tone Ring Replacement

Replace the tone ring with a new, OEM-quality tone ring. Ensure that the new tone ring is properly aligned and secured to the crankshaft or camshaft.

5.5. Additional Repairs

5.5.1. Crankshaft Balancer Replacement

If the crankshaft balancer is improperly torqued or damaged, replace it with a new, OEM-quality balancer. Ensure that the new balancer is properly torqued to the manufacturer’s specifications.

5.5.2. CMP Actuator Solenoid Replacement

If the CMP actuator solenoid is stuck or malfunctioning, replace it with a new, OEM-quality solenoid. Ensure that the new solenoid is properly installed and connected.

6. Preventative Maintenance for Avoiding the P0018 Code

Preventative maintenance can help prevent the occurrence of the P0018 code and other engine-related issues. Here are some essential maintenance tasks:

6.1. Regular Oil Changes

Regular oil changes are crucial for maintaining the health of the engine and its components. Use the recommended oil type and change it at the intervals specified by the manufacturer.

6.2. Timing Chain/Belt Inspection

Regularly inspect the timing chain or belt for signs of wear, stretching, or damage. Replace the timing chain or belt at the intervals specified by the manufacturer to prevent timing misalignment.

6.3. Sensor Maintenance

Keep the CKP and CMP sensors clean and free from debris. Inspect the wiring and connectors for damage or corrosion. Replace the sensors as needed to ensure accurate readings.

6.4. Tensioner Maintenance

Regularly inspect the timing chain tensioner for proper operation. Replace the tensioner as needed to maintain proper tension on the timing chain.

6.5. Scheduled Maintenance

Follow the manufacturer’s recommended maintenance schedule for all engine components. This includes checking and replacing fluids, filters, and other wear items as needed.

7. Tools and Equipment for Diagnosing and Repairing P0018

Having the right tools and equipment is essential for effectively diagnosing and repairing the P0018 code. Here is a list of recommended tools:

7.1. OBD2 Scanner

An OBD2 scanner is essential for reading and clearing diagnostic trouble codes (DTCs) from the PCM. Choose a scanner that is compatible with your vehicle’s make and model.

7.2. Multimeter

A multimeter is necessary for testing the CKP and CMP sensors, as well as the wiring and connectors. Choose a multimeter with the appropriate voltage, resistance, and continuity testing capabilities.

7.3. Oscilloscope

An oscilloscope is useful for analyzing the waveforms of the CKP and CMP sensors. Choose an oscilloscope with the appropriate bandwidth and sampling rate for automotive diagnostics.

7.4. Timing Light

A timing light is necessary for checking and adjusting the engine timing. Choose a timing light that is compatible with your vehicle’s ignition system.

7.5. Socket Set and Wrenches

A comprehensive socket set and wrench set are essential for removing and installing engine components. Choose a set with a variety of sizes and types of sockets and wrenches.

7.6. Torque Wrench

A torque wrench is necessary for tightening engine components to the manufacturer’s specifications. Choose a torque wrench with the appropriate torque range and accuracy.

7.7. Wire Strippers and Crimpers

Wire strippers and crimpers are essential for repairing damaged wiring and connectors. Choose high-quality wire strippers and crimpers that are designed for automotive use.

7.8. Diagnostic Software

Diagnostic software can provide additional information and capabilities for diagnosing and repairing the P0018 code. Choose software that is compatible with your vehicle’s make and model.

8. The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in Addressing P0018

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are dedicated to providing comprehensive solutions and expert guidance for diagnosing and resolving the P0018 code. Here’s how we can assist you:

8.1. Expert Diagnostic Services

Our team of experienced technicians is equipped with advanced diagnostic tools and expertise to accurately diagnose the root cause of the P0018 code in your Mercedes. We perform thorough inspections, sensor testing, and timing component analysis to identify the underlying issue.

8.2. High-Quality Repair Solutions

We offer high-quality repair solutions using OEM-quality parts and proven repair techniques. Our technicians are skilled in replacing faulty sensors, repairing wiring and connectors, and replacing timing components to restore your engine’s performance and reliability.

8.3. Advanced Diagnostic Tools and Equipment

We utilize state-of-the-art diagnostic tools and equipment, including OBD2 scanners, multimeters, oscilloscopes, and diagnostic software, to ensure accurate and efficient diagnosis and repair of the P0018 code.

8.4. Comprehensive Guides and Resources

Our website, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, provides comprehensive guides, resources, and troubleshooting tips for diagnosing and repairing the P0018 code. We offer step-by-step instructions, diagrams, and videos to help you understand the diagnostic and repair process.

8.5. Personalized Support and Consultation

We offer personalized support and consultation to assist you with your diagnostic and repair needs. Our team of experts is available to answer your questions, provide technical assistance, and guide you through the repair process.

9. Case Studies: Resolving P0018 in Mercedes Vehicles

To illustrate the diagnostic and repair process for the P0018 code, here are a few case studies involving Mercedes vehicles:

9.1. Case Study 1: 2015 Mercedes-Benz C300

A 2015 Mercedes-Benz C300 with 80,000 miles exhibited the P0018 code along with reduced engine performance and poor fuel economy. The technician performed a thorough inspection and found that the CMP sensor on bank 2 was faulty. The CMP sensor was replaced with a new, OEM-quality sensor, and the P0018 code was cleared. The engine performance and fuel economy returned to normal.

9.2. Case Study 2: 2012 Mercedes-Benz E350

A 2012 Mercedes-Benz E350 with 120,000 miles displayed the P0018 code along with engine misfires and difficult starting. The technician inspected the timing chain and found that it was stretched. The timing chain, tensioner, and guides were replaced with a new, OEM-quality timing chain kit. The engine started smoothly, and the misfires were resolved.

9.3. Case Study 3: 2018 Mercedes-Benz GLC300

A 2018 Mercedes-Benz GLC300 with 40,000 miles showed the P0018 code. The technician found damaged wiring to the CKP sensor. The damaged wiring was repaired using proper splicing techniques, and the P0018 code was cleared. The engine performance returned to normal.

10. Frequently Asked Questions (FAQs) About the P0018 Code

Here are some frequently asked questions about the P0018 code:

10.1. What is the most common cause of the P0018 code?

The most common cause is a stretched timing chain or a faulty CMP sensor.

10.2. Can I drive my car with the P0018 code?

It is not recommended to drive with the P0018 code, as it can lead to reduced engine performance and potential engine damage.

10.3. How much does it cost to fix the P0018 code?

The cost to fix the P0018 code varies depending on the underlying cause and the extent of the repairs needed. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for an accurate estimate.

10.4. Can a bad CKP sensor cause the P0018 code?

Yes, a bad CKP sensor can cause the P0018 code.

10.5. Can a bad CMP sensor cause the P0018 code?

Yes, a bad CMP sensor can cause the P0018 code.

10.6. How do I test the CKP sensor?

You can test the CKP sensor using a multimeter to check its resistance and voltage.

10.7. How do I test the CMP sensor?

You can test the CMP sensor using a multimeter to check its resistance and voltage.

10.8. What tools do I need to diagnose the P0018 code?

You will need an OBD2 scanner, a multimeter, and possibly an oscilloscope.

10.9. How often should I replace the timing chain?

The timing chain should be replaced at the intervals specified by the manufacturer, typically between 80,000 and 120,000 miles.

10.10. Where can I get help diagnosing and repairing the P0018 code?

Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert diagnostic services and high-quality repair solutions.

11. Conclusion

The P0018 code indicates a timing misalignment between the crankshaft and camshaft, which can lead to reduced engine performance and potential engine damage. Diagnosing and repairing the P0018 code requires a systematic approach and the right tools and equipment. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we are committed to providing expert diagnostic services, high-quality repair solutions, and personalized support to help you resolve the P0018 code and keep your Mercedes running smoothly.

Don’t let the P0018 code compromise your vehicle’s performance. Contact us today at 789 Oak Avenue, Miami, FL 33101, United States or via Whatsapp at +1 (641) 206-8880. Visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN to learn more about our services and how we can help you resolve your diagnostic and repair needs. Get in touch now for expert assistance with diagnostic tools, unlocking hidden features, and professional guidance for Mercedes-Benz maintenance.