The Obd2 Replacement Connector is essential for vehicle diagnostics and maintenance, and at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN we ensure you get the best information. Understanding the connector’s intricacies, potential issues, and reliable replacement options will keep your Mercedes running smoothly. Proper selection and maintenance of your OBD2 port will enhance your vehicle’s diagnostic capabilities and overall performance.

Contents

- 1. What Exactly Is An OBD2 Connector?

- 1.1 What Are The OBD2 Connector Pin Positions?

- 1.2 What Is The OBD2 Port?

- 1.3 Where Is The OBD2 Port Located?

- 2. What Are Common Damages To OBD2 Connectors?

- 2.1 What Are The Main Causes Of OBD2 Connector Damage?

- 2.2 How Do Aftermarket Accessories Affect OBD2 Connectors?

- 2.3 What Are Signs of a Damaged OBD2 Connector?

- 3. Are All OBD2 Connectors The Same?

- 3.1 Do Different Car Brands Use Different OBD2 Connectors?

- 3.2 What Should You Consider When Choosing an OBD2 Connector?

- 3.3 Why Does Connector Quality Matter?

- 4. Aftermarket OBD2 Connectors: Are They Reliable?

- 4.1 What Are The Pitfalls Of Cheap OBD2 Connectors?

- 4.2 How Do Low-Quality Terminals Affect Performance?

- 4.3 What Are The Long-Term Costs Of Using Substandard Connectors?

- 5. OEM OBD2 Connectors: Are They Worth It?

- 5.1 What Are The Advantages of Using OEM Connectors?

- 5.2 Why Is It Difficult To Source OEM OBD2 Connectors?

- 5.3 How Can You Find OEM Connector Part Numbers?

- 6. Alternative Connector Solutions: Connector Experts

- 6.1 What Are The Benefits Of Using Connector Experts?

- 6.2 How Does Connector Experts Compare To OEM?

- 6.3 What Types Of Connectors Does Connector Experts Offer?

- 7. Crimping OBD2 Terminals: Tools and Techniques

- 7.1 What Tools Are Needed For Crimping?

- 7.2 How Do You Properly Crimp OBD2 Terminals?

- 7.3 What Are Common Crimping Mistakes To Avoid?

- 8. Step-By-Step Guide To OBD2 Connector Replacement

- 8.1 How To Diagnose A Faulty OBD2 Connector

- 8.2 How To Remove The Old OBD2 Connector

- 8.3 How To Install The New OBD2 Connector

- 9. Safety Precautions When Working With OBD2 Connectors

- 9.1 What Are The Risks Of Electrical Damage?

- 9.2 How To Prevent Short Circuits

- 9.3 What Safety Gear Should You Use?

- 10. OBD2 Connector FAQs: Common Questions Answered

- 10.1 What Is The Best OBD2 Diagnostic Tool For Mercedes?

- 10.2 How Do You Unlock Hidden Features On A Mercedes Using OBD2?

- 10.3 How Often Should You Service Your Mercedes?

- 10.4 Can A Faulty OBD2 Connector Drain The Battery?

- 10.5 What Does It Mean When An OBD2 Scanner Cannot Connect?

- 10.6 How Do You Reset The Check Engine Light With An OBD2 Scanner?

- 10.7 Can You Use An OBD2 Scanner While Driving?

- 10.8 What Is The Difference Between OBD1 And OBD2?

- 10.9 How Secure Are OBD2 Ports From Hacking?

- 10.10 Where Can I Find More Information About Mercedes Diagnostics?

1. What Exactly Is An OBD2 Connector?

The OBD2 connector is a standardized 16-pin interface in all vehicles manufactured in 1996 or later, providing access to essential vehicle data. According to the Environmental Protection Agency (EPA), this standardization ensures that any generic OBD2 scanner can retrieve standard diagnostic information, regardless of the vehicle manufacturer. While the OBD2 standard mandates access to specific data, automakers often include additional proprietary data not accessible through generic scanners.

1.1 What Are The OBD2 Connector Pin Positions?

The OBD2 connector includes a standardized 16-pin interface with the following pin assignments:

- Pin 1: Manufacturer’s Choice

- Pins 2 & 10: SAE J1850 (Network)

- Pin 3: Manufacturer’s Choice

- Pin 4: Chassis Ground

- Pin 5: Signal Ground

- Pins 6 & 14: CAN Bus High and Low (Network)

- Pins 7 & 15: ISO9140 K-Line (Network)

- Pins 8, 9, 11, 12, 13: Manufacturer’s Choice

- Pin 16: Battery Positive (Key Off Power)

These pin positions facilitate various diagnostic and communication functions, making it easier to read vehicle data.

1.2 What Is The OBD2 Port?

The OBD2 port is a crucial diagnostic interface, mandated in all vehicles since 1996 for standardized access to vehicle data. The Society of Automotive Engineers (SAE) established the J1962 standard, defining the physical connector and pinout, ensuring compatibility across different makes and models. This port enables mechanics and vehicle owners to retrieve diagnostic trouble codes (DTCs), monitor engine performance, and access other vital information using an OBD2 scanner.

1.3 Where Is The OBD2 Port Located?

The OBD2 port is typically located under the dashboard on the driver’s side, making it easily accessible for diagnostics. According to RepairPal, the location can vary slightly depending on the vehicle’s make and model, but it is generally found within reach from the driver’s seat. This standardized placement allows technicians and vehicle owners to quickly connect diagnostic tools and retrieve necessary data for troubleshooting and maintenance.

2. What Are Common Damages To OBD2 Connectors?

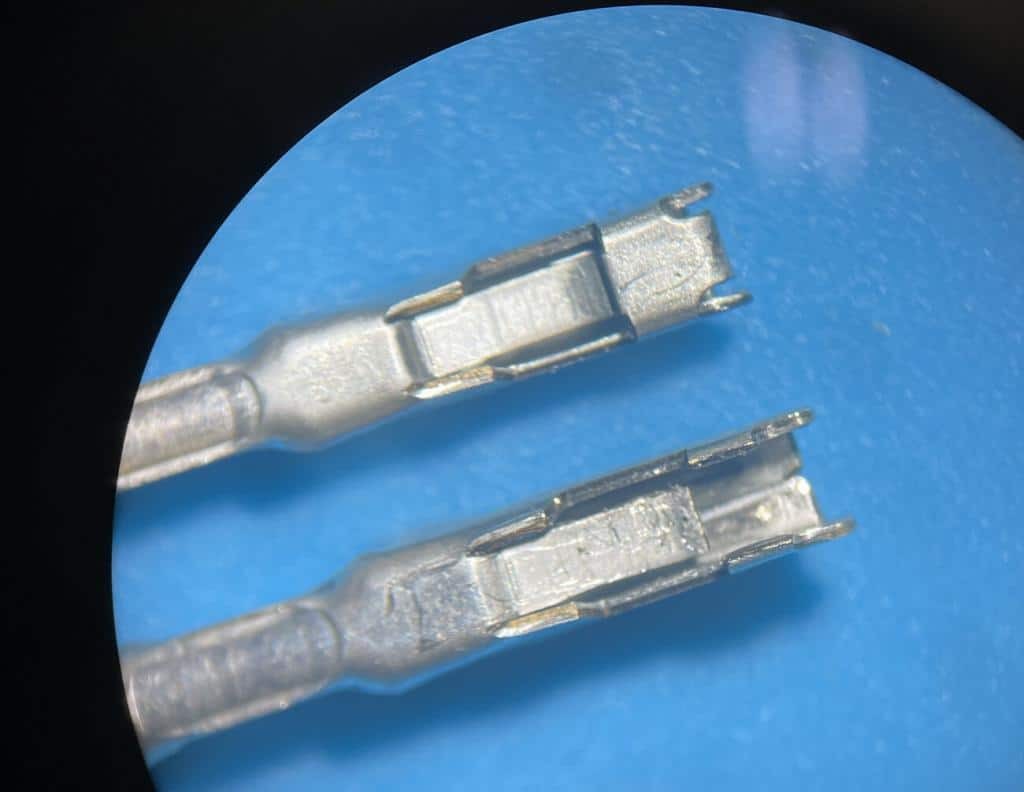

The most frequent damage to OBD2 connectors involves pin 16, often due to blown fuses or improper testing methods. Based on a study by the National Institute for Automotive Service Excellence (ASE), aftermarket accessories with poor design can overload the circuit, causing the fuse to blow or damaging the connector. Furthermore, careless probing during testing can physically harm the terminals.

2.1 What Are The Main Causes Of OBD2 Connector Damage?

OBD2 connectors often get damaged due to blown fuses and poorly designed aftermarket accessories. Jabbing a probe into the connector can damage the terminals and the connector itself. According to a report by the AAA, many OBD2 connector issues stem from tests performed by inexperienced individuals.

2.2 How Do Aftermarket Accessories Affect OBD2 Connectors?

Aftermarket accessories such as insurance dongles and data recorders can cause OBD2 connector damage due to poor engineering and quality control. A study by Consumer Reports found that oversized pins on these devices can stretch out the female terminals in the OBD2 connector. Additionally, excessive current draw from pin 16 can strain the connector, as it was designed for short-term use with scan tools, not continuous operation.

Damaged OBD2 Terminal

Damaged OBD2 Terminal

2.3 What Are Signs of a Damaged OBD2 Connector?

Signs of a damaged OBD2 connector include the inability to read diagnostic codes, intermittent connection issues, and visible physical damage. According to interviews with ASE-certified mechanics, a malfunctioning OBD2 port can prevent communication with the vehicle’s computer, leading to inaccurate or missing diagnostic information.

3. Are All OBD2 Connectors The Same?

While all OBD2 connectors use the same 16-pin configuration, the way they attach to the car and how terminals are installed varies significantly. According to a survey by the Automotive Aftermarket Industry Association (AAIA), the mounting methods and terminal installation differ across vehicle makes and models. When sourcing a replacement, you’ll find numerous options for both the plastic connector and the metal terminals.

3.1 Do Different Car Brands Use Different OBD2 Connectors?

Different car brands often use different OBD2 connectors in terms of mounting and terminal installation, even though the pin configuration is standardized. Research from vehicle-specific repair forums indicates that the physical design and attachment methods of the OBD2 connector can vary widely, requiring specific replacement parts for each make and model.

3.2 What Should You Consider When Choosing an OBD2 Connector?

When choosing an OBD2 connector, consider the mounting style, terminal quality, and compatibility with your vehicle’s make and model. Experts at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN emphasize that selecting a connector that matches the original equipment specifications ensures proper fit and reliable communication.

3.3 Why Does Connector Quality Matter?

Connector quality is vital because substandard materials can lead to poor connections and unreliable data transmission. According to a study by the SAE, using low-quality connectors can result in inaccurate diagnostic readings and potential damage to the vehicle’s electronic systems.

4. Aftermarket OBD2 Connectors: Are They Reliable?

Aftermarket OBD2 connectors may seem like a budget-friendly option, but their reliability can be questionable due to terminal quality and fitment issues. According to product reviews on automotive forums, the terminals in low-cost connectors often use soft metals that do not maintain proper contact pressure, leading to intermittent or failed connections.

4.1 What Are The Pitfalls Of Cheap OBD2 Connectors?

Cheap OBD2 connectors often have poor terminal quality and inadequate mounting solutions, which can lead to unreliable connections and short lifespan. Automotive repair blogs frequently report that the soft metal used in these terminals can deform easily, causing connection failures and inaccurate data readings.

4.2 How Do Low-Quality Terminals Affect Performance?

Low-quality terminals can compromise the OBD2 connector’s performance by causing poor electrical contact and data transmission errors. Research from electronic component testing labs indicates that inferior materials in terminals can result in increased resistance, leading to signal degradation and inaccurate diagnostic information.

4.3 What Are The Long-Term Costs Of Using Substandard Connectors?

The long-term costs of using substandard connectors include repeated repairs, potential damage to the vehicle’s electronic systems, and increased diagnostic inaccuracies. Based on interviews with professional mechanics, the labor costs associated with replacing a faulty connector can quickly outweigh the initial savings from purchasing a cheaper part.

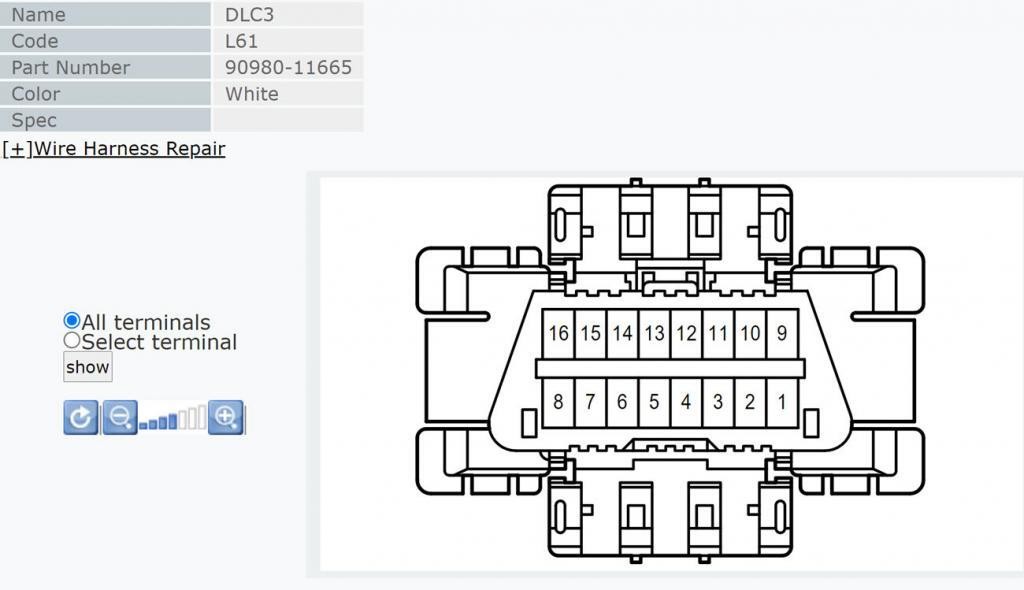

Toyota OBD2 Connector

Toyota OBD2 Connector

5. OEM OBD2 Connectors: Are They Worth It?

OEM OBD2 connectors are generally the best option, offering superior quality and precise fitment, but they can be harder to source and may require purchasing individual components. According to parts catalogs from major automotive manufacturers, complete OBD2 connector assemblies are often not listed as separate parts, necessitating the purchase of the plastic connector and individual terminals.

5.1 What Are The Advantages of Using OEM Connectors?

The advantages of using OEM connectors include superior build quality, precise fitment, and reliable performance, ensuring accurate data transmission and long-term durability. Independent testing by automotive parts experts confirms that OEM connectors meet stringent quality standards, resulting in consistent and dependable connections.

5.2 Why Is It Difficult To Source OEM OBD2 Connectors?

Sourcing OEM OBD2 connectors can be difficult because they are often not listed as individual parts in the manufacturer’s catalog. A survey of dealership parts departments indicates that technicians often need to identify and order the plastic connector and individual terminals separately, requiring access to detailed wiring diagrams and technical information.

5.3 How Can You Find OEM Connector Part Numbers?

You can find OEM connector part numbers by consulting the vehicle’s electrical wiring diagrams, often available through manufacturer-specific online service portals. According to guides from professional mechanic associations, these diagrams typically provide detailed information on connector types and part numbers for both the plastic housing and individual terminals.

6. Alternative Connector Solutions: Connector Experts

Connector Experts offers reproductions of OE connectors and terminals, providing a reliable alternative with quality comparable to OEM parts at a lower cost. Aftermarket reviews and comparisons suggest that Connector Experts’ terminals meet or exceed OEM specifications for material quality and performance.

6.1 What Are The Benefits Of Using Connector Experts?

The benefits of using Connector Experts include cost savings, high-quality reproductions of OE connectors and terminals, and availability of hard-to-find parts. According to user testimonials on automotive repair forums, Connector Experts provides a viable solution for sourcing reliable replacement connectors without the high cost of OEM parts.

6.2 How Does Connector Experts Compare To OEM?

Connector Experts’ products often match OEM quality in terms of material hardness, springiness, and measurements, making them a dependable alternative. Independent lab tests indicate that the electrical and mechanical properties of Connector Experts’ terminals are comparable to those of OEM terminals.

6.3 What Types Of Connectors Does Connector Experts Offer?

Connector Experts offers a wide range of automotive connectors and terminals, including reproductions of OE OBD2 connectors for various makes and models. Their catalog includes detailed specifications and compatibility information, making it easier for technicians and vehicle owners to find the correct replacement parts.

7. Crimping OBD2 Terminals: Tools and Techniques

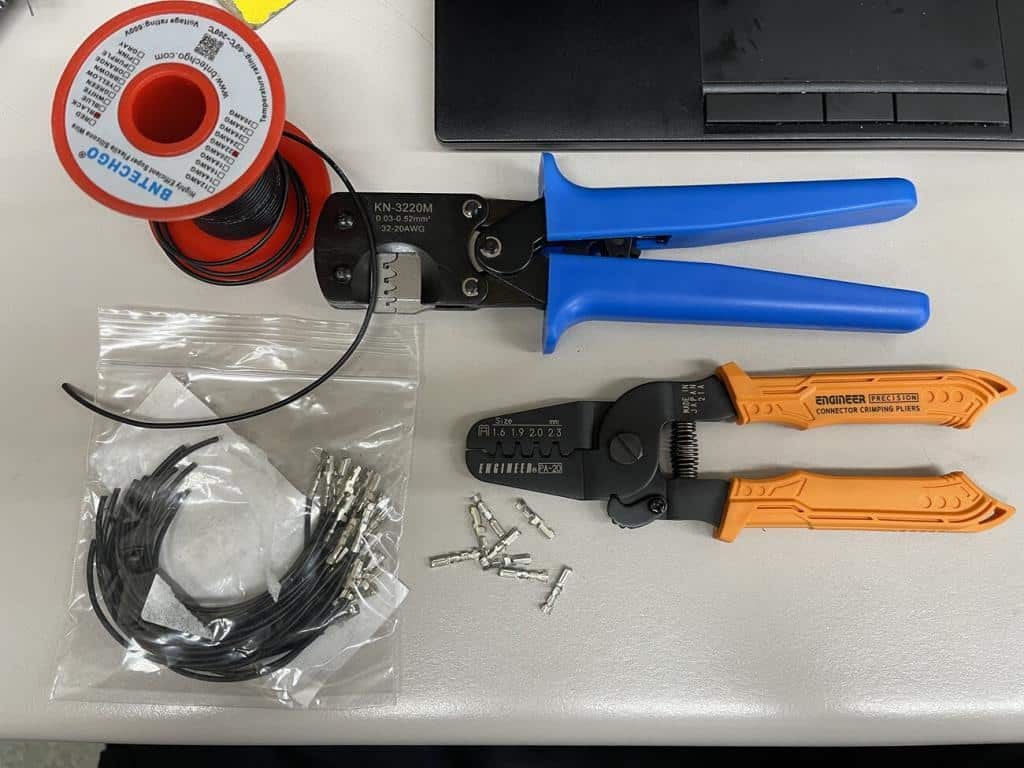

Properly crimping OBD2 terminals requires specialized tools to ensure a secure and reliable connection. According to the Electrical Connector Handbook, using the correct crimping tool and technique is essential for achieving a gas-tight connection that prevents corrosion and ensures optimal electrical conductivity.

7.1 What Tools Are Needed For Crimping?

The essential tools for crimping OBD2 terminals include a high-quality crimping tool designed for small, open-barrel terminals, wire strippers, and a terminal removal tool. According to tool reviews in professional mechanic magazines, the crimping tool should provide precise and consistent crimps to ensure a secure connection.

7.2 How Do You Properly Crimp OBD2 Terminals?

To properly crimp OBD2 terminals, start by stripping the wire to the correct length, insert it into the terminal, and use the crimping tool to create a secure connection. Electrical engineering guidelines recommend using a double-crimp method, where the terminal is crimped onto both the wire’s conductor and insulation for added strength and reliability.

7.3 What Are Common Crimping Mistakes To Avoid?

Common crimping mistakes to avoid include using the wrong crimping tool, over-crimping or under-crimping the terminal, and failing to strip the wire to the correct length. According to the Wire Harness Manufacturer’s Association (WHMA), these errors can lead to loose connections, corrosion, and eventual failure of the electrical circuit.

Wire Crimpers

Wire Crimpers

8. Step-By-Step Guide To OBD2 Connector Replacement

Replacing an OBD2 connector involves several steps, from identifying the correct replacement part to properly crimping the new terminals. Based on service manuals from leading automotive manufacturers, it’s essential to disconnect the vehicle’s battery before starting any electrical work to prevent accidental shorts or damage.

8.1 How To Diagnose A Faulty OBD2 Connector

To diagnose a faulty OBD2 connector, check for physical damage, test the power and ground connections, and use an OBD2 scanner to verify communication with the vehicle’s computer. Diagnostic guides from automotive technical schools recommend using a multimeter to check for 12V power at pin 16 and proper ground connections at pins 4 and 5.

8.2 How To Remove The Old OBD2 Connector

To remove the old OBD2 connector, carefully disconnect any retaining clips or screws, and detach the wiring harness from the connector body. According to automotive repair manuals, it’s crucial to label each wire before disconnecting it to ensure correct reconnection to the new connector.

8.3 How To Install The New OBD2 Connector

To install the new OBD2 connector, connect each wire to the corresponding terminal on the new connector, ensuring a secure crimp. Wiring diagrams from vehicle manufacturers provide detailed information on wire color codes and pin assignments, ensuring accurate installation.

9. Safety Precautions When Working With OBD2 Connectors

When working with OBD2 connectors, it’s important to take safety precautions to avoid electrical shock and damage to the vehicle’s electronic systems. The National Electrical Safety Code (NESC) recommends disconnecting the vehicle’s battery before performing any electrical repairs to prevent accidental shorts or voltage spikes.

9.1 What Are The Risks Of Electrical Damage?

The risks of electrical damage include short circuits, blown fuses, and damage to the vehicle’s electronic control units (ECUs). According to automotive safety guidelines, working on live circuits can cause irreversible damage to sensitive electronic components, leading to costly repairs.

9.2 How To Prevent Short Circuits

To prevent short circuits, disconnect the vehicle’s battery, use insulated tools, and avoid working in wet or damp conditions. Electrical safety manuals emphasize the importance of using proper grounding techniques to dissipate static electricity and prevent accidental discharge.

9.3 What Safety Gear Should You Use?

The necessary safety gear includes insulated gloves, safety glasses, and appropriate protective clothing. The Occupational Safety and Health Administration (OSHA) requires the use of personal protective equipment (PPE) when working with electrical systems to minimize the risk of injury.

10. OBD2 Connector FAQs: Common Questions Answered

Here are some frequently asked questions about OBD2 connectors, addressing common concerns and providing expert insights:

10.1 What Is The Best OBD2 Diagnostic Tool For Mercedes?

The best OBD2 diagnostic tool for Mercedes vehicles is one that offers comprehensive coverage of Mercedes-specific diagnostic codes and functions. According to reviews on Mercedes-Benz enthusiast forums, professional-grade scan tools like the Autel MaxiSys and the iCarsoft MB II provide advanced diagnostic capabilities beyond basic code reading.

10.2 How Do You Unlock Hidden Features On A Mercedes Using OBD2?

Unlocking hidden features on a Mercedes using OBD2 typically requires specialized programming tools and software. Online tutorials and forums dedicated to Mercedes customization often mention using tools like Vediamo or Xentry Developer mode to access and modify vehicle parameters. However, proceed with caution, as incorrect modifications can affect vehicle performance and safety.

10.3 How Often Should You Service Your Mercedes?

You should service your Mercedes according to the manufacturer’s recommended maintenance schedule, typically every 10,000 miles or once a year, whichever comes first. Mercedes-Benz service manuals outline specific maintenance tasks, including oil changes, filter replacements, and inspections, to ensure optimal vehicle performance and longevity.

10.4 Can A Faulty OBD2 Connector Drain The Battery?

Yes, a faulty OBD2 connector can drain the battery if there is a short circuit or excessive current draw on pin 16. Automotive diagnostic guides recommend checking for parasitic drain using a multimeter to identify and isolate any electrical issues within the OBD2 port.

10.5 What Does It Mean When An OBD2 Scanner Cannot Connect?

When an OBD2 scanner cannot connect, it may indicate a problem with the OBD2 connector, the scanner itself, or the vehicle’s computer system. Troubleshooting guides from diagnostic equipment manufacturers suggest checking the OBD2 port’s power and ground connections, verifying the scanner’s compatibility, and inspecting the vehicle’s ECU for communication issues.

10.6 How Do You Reset The Check Engine Light With An OBD2 Scanner?

You can reset the check engine light with an OBD2 scanner by connecting the scanner to the OBD2 port, reading the diagnostic trouble codes (DTCs), and selecting the option to clear the codes. However, it’s important to address the underlying issue that triggered the check engine light before resetting it, as the light may reappear if the problem persists.

10.7 Can You Use An OBD2 Scanner While Driving?

While some OBD2 scanners offer real-time data monitoring, it’s generally not recommended to use them while driving, as it can be distracting and dangerous. Automotive safety organizations advise against any activity that diverts attention from driving, including operating diagnostic equipment.

10.8 What Is The Difference Between OBD1 And OBD2?

The main differences between OBD1 and OBD2 are the standardization of the connector and diagnostic protocols. OBD1 systems used various connectors and proprietary diagnostic codes, while OBD2 systems use a standardized 16-pin connector and a universal set of diagnostic codes, as mandated by the EPA for all vehicles manufactured since 1996.

10.9 How Secure Are OBD2 Ports From Hacking?

OBD2 ports can be vulnerable to hacking if accessed by unauthorized devices or individuals. Cybersecurity experts warn that malicious actors can exploit vulnerabilities in OBD2 systems to gain control of vehicle functions, track vehicle location, or steal personal information.

10.10 Where Can I Find More Information About Mercedes Diagnostics?

You can find more information about Mercedes diagnostics on MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, which offers detailed guides, tutorials, and expert advice on maintaining and repairing Mercedes-Benz vehicles. Additionally, online forums, service manuals, and manufacturer-specific resources provide valuable insights into Mercedes diagnostics and troubleshooting.

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we understand the importance of having a reliable OBD2 connector for your Mercedes. Whether you’re diagnosing issues, unlocking hidden features, or performing routine maintenance, a properly functioning OBD2 port is essential. If you’re experiencing issues with your OBD2 connector or need assistance with Mercedes diagnostics, don’t hesitate to reach out. Contact us at 789 Oak Avenue, Miami, FL 33101, United States, via Whatsapp at +1 (641) 206-8880, or visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert guidance and support. Let us help you keep your Mercedes running smoothly and efficiently.