What Can I Do With Obd2? With an OBD2 scanner, you can unlock a world of vehicle diagnostics and customization. This guide from MERCEDES-DIAGNOSTIC-TOOL.EDU.VN will explore the many possibilities of using OBD2, from reading diagnostic trouble codes to accessing real-time data. Discover how OBD2 tools can empower you to maintain your Mercedes-Benz efficiently. This includes using scan tools, accessing vehicle data, and potential modifications.

Contents

- 1. Understanding the Power of OBD2: An Introduction

- 2. Does My Mercedes-Benz Support OBD2?

- 3. Delving into the History of OBD2: From Emissions to Empowerment

- 4. Unveiling the Potential: What Can You Do with OBD2?

- 5. Navigating the OBD2 Connector: Your Gateway to Vehicle Data

- 5.1 OBD2 Connector: Type A vs. Type B

- 6. Choosing the Right OBD2 Tool: Scanners, Adapters, and Apps

- 6.1 Factors to Consider When Choosing an OBD2 Tool:

- 7. Connecting to Your Mercedes-Benz: A Step-by-Step Guide

- 8. Deciphering Diagnostic Trouble Codes (DTCs): Understanding the Check Engine Light

- 8.1 Understanding the DTC Structure:

- 8.2 Using DTCs for Diagnosis:

- 8.3 Clearing DTCs: Proceed with Caution:

- 9. Monitoring Real-Time Data: A Window into Your Engine’s Performance

- 9.1 Common Real-Time Data Parameters:

- 9.2 Using Real-Time Data for Diagnosis:

- 10. Exploring Advanced Functions: Beyond Basic Diagnostics

- 10.1 Unlocking Hidden Features:

- 11. The Future of OBD2: What’s on the Horizon?

- 12. Real-World Applications: OBD2 in Action

- 13. Troubleshooting Common OBD2 Issues:

- 14. OBD2 and CAN Bus: Understanding the Underlying Communication

- 15. Safety Precautions: Working with Your Vehicle’s Electronics

- 16. OBD2 Parameter IDs (PIDs): Your Key to Unlocking Vehicle Data

- 17. How to Log and Decode OBD2 Data

- 17.1: Test bit-rate, IDs & supported PIDs

- 17.2: Configure OBD2 PID requests

- 17.3: DBC decode raw OBD2 data

- 18. Multi-Frame Examples [ISO-TP]

- 18.1: OBD2 Vehicle Identification Number (VIN)

- 18.2: OBD2 multi-PID request (6x)

- 18.3: OBD2 Diagnostic Trouble Codes (DTCs)

- 19. Frequently Asked Questions (FAQs) About OBD2

- 19.1: What is the best OBD2 scanner for Mercedes-Benz?

- 19.2: How do I find the OBD2 port in my Mercedes-Benz?

- 19.3: Can I use OBD2 to improve my fuel economy?

- 19.4: Is it safe to clear DTCs myself?

- 19.5: What is the difference between OBD2 and CAN bus?

- 19.6: Can I unlock hidden features on my Mercedes-Benz with OBD2?

- 19.7: How often should I scan my Mercedes-Benz with an OBD2 scanner?

- 19.8: What does it mean when my OBD2 scanner says “No Codes Found”?

- 19.9: How do I update the software on my OBD2 scanner?

- 19.10: Where can I find more information about OBD2?

- 20. The MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Advantage: Your Partner in Mercedes-Benz Diagnostics

1. Understanding the Power of OBD2: An Introduction

OBD2, or On-Board Diagnostics II, is your car’s internal health monitor. It’s a standardized system that allows you to access a wealth of information about your vehicle’s performance and identify potential issues. Think of it as a window into your car’s brain. OBD2 is a gateway to car diagnostics, live data streaming, and even some customization options, making it an indispensable tool for car enthusiasts, technicians, and Mercedes-Benz owners alike.

2. Does My Mercedes-Benz Support OBD2?

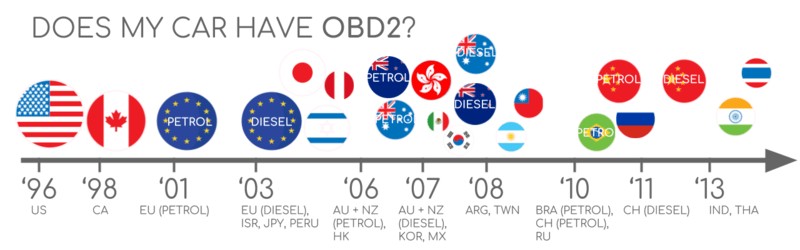

The good news is, if you own a Mercedes-Benz manufactured after 1996, it almost certainly supports OBD2. This standardization was mandated in the United States for all passenger cars and light trucks starting in 1996. So, chances are, your Mercedes-Benz has an OBD2 port, typically located under the dashboard on the driver’s side. While most cars support OBD2, it’s still important to make sure that your car is compliant. You can check where and when your car was bought new.

Does My Car Have OBD2?

Does My Car Have OBD2?

3. Delving into the History of OBD2: From Emissions to Empowerment

OBD2’s roots lie in California’s push for cleaner air. In 1991, the California Air Resources Board (CARB) mandated OBD systems in new cars to monitor emissions. The Society of Automotive Engineers (SAE) played a crucial role in standardizing the technology, leading to the development of the SAE J1962 standard, which defined the connector and diagnostic trouble codes.

This standardization paved the way for wider adoption:

- 1996: OBD2 becomes mandatory in the USA for cars and light trucks.

- 2001: Required in the EU for gasoline cars.

- 2003: Required in the EU for diesel cars (EOBD).

- 2005: OBD2 required in US for medium duty vehicles.

- 2008: US cars must use ISO 15765-4 (CAN) as OBD2 basis.

- 2010: OBD2 was required in US heavy duty vehicles

The evolution of OBD2 reflects a shift from solely focusing on emissions control to providing broader diagnostic capabilities and opening up possibilities for vehicle data access.

4. Unveiling the Potential: What Can You Do with OBD2?

OBD2 offers a wide array of possibilities for Mercedes-Benz owners and enthusiasts. Here are some key functions:

- Reading Diagnostic Trouble Codes (DTCs): Identify the source of a check engine light or other warning indicators.

- Clearing DTCs: Reset the check engine light after addressing the underlying issue.

- Accessing Real-Time Data: Monitor various engine parameters like speed, RPM, coolant temperature, and more.

- Performing Emissions Tests: Check your vehicle’s readiness for emissions inspections.

- Retrieving Vehicle Information: Obtain the Vehicle Identification Number (VIN) and other identifying information.

- Unlock Hidden Features: Depending on the vehicle and tool, you can enable/disable certain car features.

5. Navigating the OBD2 Connector: Your Gateway to Vehicle Data

The OBD2 connector is a standardized 16-pin port, typically located under the dashboard on the driver’s side of your Mercedes-Benz. It’s your physical connection point for accessing vehicle data.

Key things to note about the OBD2 connector:

- Pin 16 provides battery power.

- The pinout arrangement depends on the communication protocol used by your car.

- CAN bus (Controller Area Network) is the most common lower-layer protocol, utilizing pins 6 (CAN-H) and 14 (CAN-L).

5.1 OBD2 Connector: Type A vs. Type B

You might encounter two types of OBD2 connectors: Type A and Type B. Type A is most commonly found in cars, while Type B is often used in medium and heavy-duty vehicles. The two types share similar pinouts but differ in power supply outputs (12V for Type A, 24V for Type B). Type B connectors have an interrupted groove in the middle, making them compatible with both Type A and Type B adapter cables, while Type A cables only fit Type A sockets.

6. Choosing the Right OBD2 Tool: Scanners, Adapters, and Apps

The market offers a wide variety of OBD2 tools, each with its own strengths and weaknesses. Here’s a breakdown of common types:

- Basic OBD2 Scanners: These handheld devices are primarily designed for reading and clearing DTCs. They are a cost-effective option for basic diagnostics.

- Advanced OBD2 Scanners: These scanners offer more comprehensive features, such as live data streaming, advanced diagnostic tests, and bidirectional control (the ability to send commands to the vehicle).

- OBD2 Adapters: These devices plug into the OBD2 port and communicate with your smartphone or tablet via Bluetooth or Wi-Fi. They require a compatible app to function.

- OBD2 Apps: Numerous apps are available for iOS and Android devices that can turn your smartphone or tablet into an OBD2 scanner and diagnostic tool.

6.1 Factors to Consider When Choosing an OBD2 Tool:

- Compatibility: Ensure the tool is compatible with your Mercedes-Benz model and year.

- Features: Determine the features you need based on your intended use.

- Ease of Use: Opt for a tool with a user-friendly interface and clear instructions.

- Price: Set a budget and compare prices from different brands and retailers.

- Reviews: Read user reviews to get insights into the tool’s performance and reliability.

7. Connecting to Your Mercedes-Benz: A Step-by-Step Guide

Connecting an OBD2 tool to your Mercedes-Benz is a straightforward process:

- Locate the OBD2 port: It’s typically under the dashboard on the driver’s side.

- Plug in the OBD2 tool: Ensure the tool is securely connected to the port.

- Turn on the ignition: You don’t need to start the engine, but the ignition should be in the “ON” position.

- Follow the tool’s instructions: Each tool has its own operating procedure. Refer to the user manual for specific instructions.

8. Deciphering Diagnostic Trouble Codes (DTCs): Understanding the Check Engine Light

One of the primary functions of OBD2 is to provide diagnostic trouble codes (DTCs) when a problem is detected in your vehicle. These codes are standardized and provide valuable information about the nature of the issue.

8.1 Understanding the DTC Structure:

DTCs typically consist of five characters:

- First Character: Indicates the system affected (e.g., P for Powertrain, B for Body, C for Chassis, U for Network).

- Second Character: Indicates whether the code is generic (0) or manufacturer-specific (1).

- Third Character: Indicates the specific subsystem affected (e.g., fuel system, ignition system, etc.).

- Fourth and Fifth Characters: Specify the specific fault within the subsystem.

8.2 Using DTCs for Diagnosis:

Once you retrieve a DTC, you can use online resources or a repair manual to look up its meaning. This will give you a starting point for diagnosing the problem. Keep in mind that a DTC is just a clue, not a definitive diagnosis. Further investigation is often necessary to pinpoint the root cause. You can use OBD2 to request emissions-related Diagnostic Trouble Codes (DTCs) from using mode 0x03, i.e. ‘Show stored Diagnostic Trouble Codes’. No PID is included in the request. The targeted ECU(s) will then respond with the number of DTCs they have stored (including potentially 0 if they have none), with each DTC taking up 2 data bytes. As a result, multi-frame responses are necessary when more than 2 DTCs are stored.

The 2-byte DTC value is typically split into two parts, as per ISO 15031-5/ISO 15031-6. The first 2 bits define the ‘category’, while the remaining 14 bits define a 4-digit code (displayed in hexadecimal).

8.3 Clearing DTCs: Proceed with Caution:

OBD2 tools allow you to clear DTCs, which will turn off the check engine light. However, it’s important to understand that clearing a DTC doesn’t fix the underlying problem. If the issue persists, the check engine light will eventually come back on. It’s generally recommended to only clear DTCs after you’ve diagnosed and repaired the problem.

9. Monitoring Real-Time Data: A Window into Your Engine’s Performance

Beyond reading DTCs, OBD2 allows you to access a wealth of real-time data about your engine’s performance. This data can be invaluable for monitoring your vehicle’s health, diagnosing intermittent problems, and even optimizing performance.

9.1 Common Real-Time Data Parameters:

- Engine Speed (RPM): Revolutions per minute of the engine crankshaft.

- Vehicle Speed: Current speed of the vehicle.

- Coolant Temperature: Temperature of the engine coolant.

- Intake Air Temperature: Temperature of the air entering the engine.

- Mass Airflow (MAF): The amount of air entering the engine.

- Fuel Trim: Adjustments made by the engine control unit (ECU) to the fuel mixture.

- Oxygen Sensor Readings: Voltage readings from the oxygen sensors in the exhaust system.

- Throttle Position: The position of the throttle plate.

- Engine Load: A measure of how hard the engine is working.

9.2 Using Real-Time Data for Diagnosis:

By monitoring these parameters, you can gain insights into your engine’s behavior and identify potential problems. For example, a sudden drop in coolant temperature could indicate a thermostat malfunction. Abnormal oxygen sensor readings could point to a fuel system issue.

10. Exploring Advanced Functions: Beyond Basic Diagnostics

Some advanced OBD2 tools offer features beyond basic diagnostics, such as:

- Bi-Directional Control: Allows you to send commands to the vehicle to test specific components or systems.

- Advanced Diagnostic Tests: Perform specialized tests, such as cylinder balance tests or relative compression tests.

- Programming and Coding: Some tools allow you to reprogram or recode certain vehicle modules (this is typically for advanced users only).

10.1 Unlocking Hidden Features:

Depending on your Mercedes-Benz model and the capabilities of your OBD2 tool, you may be able to unlock certain hidden features, such as:

- Activating Ambient Lighting: Enable or customize the ambient lighting system.

- Adjusting Instrument Cluster Settings: Change the appearance or functionality of the instrument cluster.

- Enabling Cornering Lights: Activate the cornering lights for improved visibility.

- Folding Mirrors on Lock: Automatically fold the side mirrors when locking the car.

Disclaimer: Modifying vehicle settings can sometimes have unintended consequences. Proceed with caution and only make changes if you are comfortable with the potential risks.

11. The Future of OBD2: What’s on the Horizon?

OBD2 technology is constantly evolving. Some key trends include:

- Wireless Connectivity: More OBD2 tools are offering wireless connectivity via Bluetooth or Wi-Fi, allowing for seamless integration with smartphones and tablets.

- Cloud-Based Diagnostics: Some systems are leveraging cloud computing to provide advanced diagnostic capabilities and remote monitoring.

- Integration with Telematics: OBD2 data is increasingly being integrated with telematics systems for fleet management, usage-based insurance, and other applications.

- OBD3 and Beyond: Next-generation OBD systems are being developed to provide more comprehensive monitoring and remote diagnostics capabilities.

OBD2 is being implemented in various ways, and has limitations in regards to data richness and lower-layer protocols. Alternatives have been developed, including WWH-OBD (World Wide Harmonized OBD) and OBDonUDS (OBD on UDS). Both seek to streamline and enhance OBD communication by leveraging the UDS protocol as basis.

The solution? OBD3 – adding telematics to all cars. Basically, OBD3 adds a small radio transponder to all cars. Using this, the car vehicle identification number (VIN) and DTCs can be sent via WiFi to a central server for checks.

12. Real-World Applications: OBD2 in Action

OBD2 is not just a theoretical concept; it has numerous practical applications:

- DIY Car Repair: Diagnose and repair common car problems yourself, saving money on mechanic fees.

- Used Car Inspections: Assess the condition of a used car before you buy it.

- Performance Tuning: Optimize your engine’s performance for better fuel economy or increased power.

- Fleet Management: Track vehicle location, monitor driver behavior, and schedule maintenance.

- Automotive Research: Analyze vehicle data to improve engine designs and develop new technologies.

Logging data from cars can e.g. be used to reduce fuel costs, improve driving, test prototype parts and insurance. OBD2 interfaces can be used to stream human-readable OBD2 data in real-time, e.g. for diagnosing vehicle issues. Cars and light trucks can be monitored via IoT OBD2 loggers in the cloud to predict and avoid breakdowns. An OBD2 logger can serve as a ‘blackbox’ for vehicles or equipment, providing data for e.g. disputes or diagnostics

13. Troubleshooting Common OBD2 Issues:

While OBD2 is a powerful tool, you may encounter some issues:

- Incompatible Tool: Make sure the tool is compatible with your Mercedes-Benz model and year.

- Connection Problems: Ensure the tool is securely connected to the OBD2 port.

- No Data Displayed: Check the tool’s settings and make sure it’s configured correctly.

- Incorrect DTCs: DTCs are just a starting point; further investigation may be needed.

- Tool Malfunction: If the tool is not working properly, try a different tool or consult the manufacturer.

14. OBD2 and CAN Bus: Understanding the Underlying Communication

Since 2008, CAN bus has been the mandatory lower-layer protocol for OBD2 in all cars sold in the US as per ISO 15765. ISO 15765-4 (aka Diagnostics over CAN or DoCAN) refers to a set of restrictions applied to the CAN standard (ISO 11898). Specifically, it standardizes the CAN interface for test equipment with focus on the physical, data link and network layer:

- The CAN bus bit-rate must be either 250K or 500K

- The CAN IDs can be 11-bit or 29-bit

- Specific CAN IDs are used for OBD requests/responses

- The diagnostic CAN frame data length must be 8 bytes

- The OBD2 adapter cable must be max 5 meters

All OBD2 communication involves request / response messages.

In most cars, 11-bit CAN IDs are used for OBD2 communication. Here, the ‘Functional Addressing’ ID is 0x7DF, which corresponds to asking all OBD2 compatible ECUs if they have data to report on the requested parameter (see ISO 15765-4). In contrast, CAN IDs 0x7E0-0x7E7 can be used to perform ‘Physical Addressing’ requests from specific ECUs (less commonly used).

ECUs can respond with 11-bit IDs 0x7E8-0x7EF. The most common response ID is 0x7E8 (ECM, Engine Control Module) and to some extent 0x7E9 (TCM, Transmission Control Module). In some vehicles (e.g. vans and light/medium/heavy duty vehicles), you may find that OBD2 communication uses extended 29-bit CAN identifiers instead of 11-bit CAN identifiers. Here, the ‘Functional Addressing’ CAN ID is 0x18DB33F1.

15. Safety Precautions: Working with Your Vehicle’s Electronics

When working with your vehicle’s electronics, it’s important to take certain safety precautions:

- Read the Manual: Always refer to the user manual for your OBD2 tool and your vehicle.

- Disconnect the Battery: Disconnect the negative battery terminal before working on electrical components.

- Avoid Short Circuits: Be careful not to create short circuits when connecting or disconnecting electrical components.

- Work in a Well-Ventilated Area: When working with the engine, ensure adequate ventilation to avoid exposure to harmful fumes.

- Seek Professional Help: If you’re not comfortable working on your vehicle’s electronics, seek professional help from a qualified mechanic.

16. OBD2 Parameter IDs (PIDs): Your Key to Unlocking Vehicle Data

Each OBD2 mode contains parameter IDs (PIDs). As an example, mode 0x01 contains ~200 standardized PIDs with real-time data on e.g. speed, RPM and fuel level. However, a vehicle does not have to support all OBD2 PIDs in a mode. In practice, most vehicles only support a small subset.

Specifically, if an emissions-related ECU supports any OBD2 services, then it must support mode 0x01 PID 0x00. In response to this PID, the vehicle ECU informs whether it supports PIDs 0x01-0x20. This makes PID 0x00 useful as a fundamental ‘OBD2 compatibility test’. Further, PIDs 0x20, 0x40, …, 0xC0 can be used to determine the support for the remaining mode 0x01 PIDs.

17. How to Log and Decode OBD2 Data

In this section we provide a practical example of how you can log OBD2 data with the CANedge CAN bus data logger. The CANedge lets you configure custom CAN frames to be transmitted which allows it to be used for e.g. OBD2 logging. Once configured, the device can be easily connected to your vehicle via our OBD2-DB9 adapter cable.

17.1: Test bit-rate, IDs & supported PIDs

ISO 15765-4 describes how to determine which bit-rate and IDs are used by a specific vehicle. You can test this with the CANedge as below:

- Send CAN frame at 500K and check if succesful (else try 250K)

- Use the identified bit-rate for subsequent communication

- Send multiple ‘Supported PIDs’ requests and review the results

- Based on response IDs you can determine 11-bit vs. 29-bit

- Based on response data you can see what PIDs are supported

Most 2008+ non-EV cars support 40-80 PIDs via 500K bit-rate, 11-bit CAN IDs and the OBD2/OBDonEDS protocol.

17.2: Configure OBD2 PID requests

You now know which OBD2 PIDs are supported by your vehicle – and what bit-rate and CAN IDs to use when requesting them. Next, you configure your transmit list with PIDs of interest. A few things to consider:

- CAN IDs: Shift to ‘Physical Addressing’ request IDs (e.g. 0x7E0) to avoid multiple responses to each request

- Spacing: Add 300-500 ms between each OBD2 request (spamming the ECUs may cause them to not respond)

- Battery drain: Use triggers to stop transmitting when the vehicle is inactive (to avoid ‘waking up’ ECUs)

- Filters: Add filters to only record OBD2 responses (e.g. if your vehicle also outputs OEM-specific CAN data)

Once configured, the device is ready to log raw OBD2 data!

17.3: DBC decode raw OBD2 data

Finally, to analyze/visualize your data, you need to decode the raw OBD2 data into ‘physical values’ (like km/h or degC). The necessary decoding information can be found in ISO 15031-5/SAE J1979 (and e.g. on Wikipedia). For convenience we provide a free OBD2 DBC file that makes it easy to DBC decode raw OBD2 data in most CAN bus software tools.

18. Multi-Frame Examples [ISO-TP]

All OBD2 data is communicated using the ISO-TP (transport protocol) as per ISO 15765-2. Most of the examples so far reflect single-frame communication. In this section, we provide some examples of multi-frame communication. Multi-frame OBD2 communication requires flow control frames (see our UDS intro). In practice, this can be done by transmitting a static flow control frame e.g. 50 ms after the initial request frame, as per the CANedge configuration example shown.

18.1: OBD2 Vehicle Identification Number (VIN)

To extract the Vehicle Identification Number from a vehicle using OBD2 requests, you use mode 0x09 and PID 0x02:

The tester tool sends a Single Frame request with the PCI field (0x02), request service identifier (0x09) and PID (0x02).

The vehicle responds with a First Frame containing the PCI, length (0x014 = 20 bytes), mode (0x49, i.e. 0x09 + 0x40) and PID (0x02). Following the PID is the byte 0x01 which is the Number Of Data Items (NODI), in this case 1 (see ISO 15031-5 / SAE J1979 for details). The remaining 17 bytes equal the VIN and can be translated from HEX to ASC.

18.2: OBD2 multi-PID request (6x)

External tools are allowed to request up to 6 mode 0x01 OBD2 PIDs in a single request frame. The ECU shall respond with data for supported PIDs (with unsupported PIDs left out of the response), if necessary across multiple frames as per ISO-TP.

18.3: OBD2 Diagnostic Trouble Codes (DTCs)

You can use OBD2 to request emissions-related Diagnostic Trouble Codes (DTCs) from using mode 0x03, i.e. ‘Show stored Diagnostic Trouble Codes’. No PID is included in the request. The targeted ECU(s) will then respond with the number of DTCs they have stored (including potentially 0 if they have none), with each DTC taking up 2 data bytes. As a result, multi-frame responses are necessary when more than 2 DTCs are stored.

19. Frequently Asked Questions (FAQs) About OBD2

19.1: What is the best OBD2 scanner for Mercedes-Benz?

The best OBD2 scanner depends on your needs and budget. Basic scanners are fine for reading and clearing DTCs, while advanced scanners offer more features.

19.2: How do I find the OBD2 port in my Mercedes-Benz?

The OBD2 port is typically located under the dashboard on the driver’s side. Consult your owner’s manual for the exact location.

19.3: Can I use OBD2 to improve my fuel economy?

Yes, by monitoring real-time data such as fuel trim and oxygen sensor readings, you can identify potential issues that could be affecting your fuel economy.

19.4: Is it safe to clear DTCs myself?

It’s generally safe to clear DTCs after you’ve diagnosed and repaired the problem. However, be aware that the check engine light will come back on if the issue persists.

19.5: What is the difference between OBD2 and CAN bus?

OBD2 is a higher-level diagnostic protocol that uses CAN bus as its underlying communication network.

19.6: Can I unlock hidden features on my Mercedes-Benz with OBD2?

It depends on your Mercedes-Benz model and the capabilities of your OBD2 tool. Some tools offer the ability to unlock certain hidden features.

19.7: How often should I scan my Mercedes-Benz with an OBD2 scanner?

You should scan your Mercedes-Benz whenever the check engine light comes on or if you suspect a problem with your vehicle’s performance.

19.8: What does it mean when my OBD2 scanner says “No Codes Found”?

It means that your vehicle’s computer has not detected any problems. However, it’s still a good idea to monitor real-time data to ensure everything is running smoothly.

19.9: How do I update the software on my OBD2 scanner?

Refer to the user manual for your specific OBD2 scanner. Most scanners can be updated via USB or Wi-Fi.

19.10: Where can I find more information about OBD2?

You can find more information about OBD2 on websites like the Society of Automotive Engineers (SAE) and the Environmental Protection Agency (EPA).

20. The MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Advantage: Your Partner in Mercedes-Benz Diagnostics

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we’re passionate about empowering Mercedes-Benz owners with the knowledge and tools they need to maintain their vehicles effectively. We offer:

- Expert Guidance: Our team of experienced technicians can provide expert guidance on choosing the right OBD2 tool for your needs.

- Comprehensive Training: We offer comprehensive training courses on OBD2 diagnostics and Mercedes-Benz repair.

- Top-Quality Tools: We offer a wide selection of top-quality OBD2 scanners, adapters, and software.

- Unlocking Hidden Features: Depending on the vehicle and tool, you can enable/disable certain car features

We believe that with the right tools and knowledge, you can take control of your Mercedes-Benz’s health and enjoy many years of trouble-free driving.

Ready to unlock the full potential of your Mercedes-Benz? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for expert advice and assistance. Visit us at 789 Oak Avenue, Miami, FL 33101, United States, or reach us via WhatsApp at +1 (641) 206-8880. Explore our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information. Let us empower you to take control of your Mercedes-Benz diagnostics and maintenance. Don’t hesitate, connect with us now!