What Is Dtc On Obd2? A Diagnostic Trouble Code (DTC) on OBD2 is a standardized code that helps pinpoint vehicle malfunctions, and at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we empower you with the knowledge to understand and address these codes effectively. By understanding DTCs, you can accurately diagnose your Mercedes-Benz, leading to timely repairs and maintenance, ultimately saving time and money, so explore how DTCs work, their interpretation, and how MERCEDES-DIAGNOSTIC-TOOL.EDU.VN can assist you in resolving vehicle issues. Dive in to learn more about engine diagnostics, fault codes, and vehicle maintenance.

Contents

- 1. Understanding DTCs: The Basics

- 1.1 What is a Diagnostic Trouble Code (DTC)?

- 1.2 The Role of OBD Systems

- 1.3 Evolution of OBD Standards: OBD-I to OBD-II

- 1.4 OBD-II vs. J1939 Compliance

- 1.5 Standardized vs. Manufacturer-Specific Codes

- 2. Decoding OBD-II DTCs: A Comprehensive Guide

- 2.1 Anatomy of a DTC: The Five Characters

- 2.2 The First Character: Identifying the Control System

- 2.3 The Second Character: Standardized or Manufacturer-Specific?

- 2.4 The Third Character: Pinpointing the Subsystem

- 2.5 The Fourth and Fifth Characters: The Specific Fault Index

- 3. Interpreting DTCs: Real-World Examples

- 3.1 Decoding a Sample DTC: P0128

- 3.2 Common DTCs and Their Meanings

- 3.3 Why DTCs Aren’t Always Enough

- 4. J1939 DTCs: Understanding Heavy-Duty Vehicle Diagnostics

- 4.1 Structure of a J1939 DTC

- 4.2 Key Fields in J1939 DTCs

- 4.3 How J1939 Differs from OBD-II

- 5. DTC Scan Tools: Choosing the Right Equipment

- 5.1 Standalone OBD-II Scanners

- 5.2 Fleet Management Solutions with DTC Tools

- 5.3 How Telematics Solutions Simplify DTC Management

- 6. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for DTC Solutions

- 6.1 Diagnostic Tools Offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

- 6.2 How to Use Our Resources for DTC Interpretation

- 6.3 Benefits of Using Our Services for Mercedes-Benz Diagnostics

- 7. Step-by-Step Guide to Diagnosing DTCs on Mercedes-Benz

- 7.1 Gathering Necessary Tools and Equipment

- 7.2 Connecting the OBD-II Scanner

- 7.3 Reading and Recording DTCs

- 7.4 Interpreting the DTCs

- 7.5 Troubleshooting and Repair

- 8. Advanced Diagnostic Techniques for Mercedes-Benz

- 8.1 Using Advanced Diagnostic Software

- 8.2 Performing Component-Level Testing

- 8.3 Analyzing Live Data Streams

- 8.4 When to Seek Professional Help

- 9. Preventing DTCs: Regular Maintenance Tips

- 9.1 Regular Vehicle Inspections

- 9.2 Following the Mercedes-Benz Maintenance Schedule

- 9.3 Monitoring Vehicle Performance

- 9.4 Proper Fluid Maintenance

- 9.5 Addressing Issues Promptly

- 10. Future Trends in OBD and DTC Technology

- 10.1 Advancements in OBD-III and Beyond

- 10.2 The Role of Artificial Intelligence (AI) in Diagnostics

- 10.3 Integration with Smart Devices

- 10.4 Cybersecurity Considerations

- FAQ: Decoding DTCs and Mercedes-Benz Diagnostics

- What is the most common reason for a check engine light to come on in a Mercedes-Benz?

- How do I find the right OBD-II scanner for my Mercedes-Benz model?

- Can I clear a DTC myself, and is it safe to do so?

- What does a manufacturer-specific DTC indicate?

- How often should I perform a diagnostic scan on my Mercedes-Benz?

- What are the key differences between OBD-II and J1939 diagnostic systems?

- Where can I find reliable information on Mercedes-Benz specific DTCs?

- How can advanced diagnostic software improve my Mercedes-Benz maintenance?

- What maintenance steps can help prevent DTCs from appearing?

- When should I seek professional help for diagnosing a DTC on my Mercedes-Benz?

1. Understanding DTCs: The Basics

A Diagnostic Trouble Code (DTC) is a code generated by a vehicle’s on-board diagnostics (OBD) system to indicate a malfunction. The Society of Automotive Engineers (SAE) has standardized these codes to ensure consistency across different vehicle manufacturers, making it easier for technicians and owners to identify and address issues. These codes are crucial for diagnosing problems, which helps in prompt maintenance and repairs.

1.1 What is a Diagnostic Trouble Code (DTC)?

A DTC, or Diagnostic Trouble Code, serves as a beacon, pinpointing malfunctions within your vehicle or heavy machinery. While the malfunction indicator lamp (MIL)—commonly known as the check engine light—simply alerts you to an issue, a DTC identifies the precise nature and location of the problem. Often referred to as engine vehicle fault codes, DTCs can be accessed using a scanner that plugs directly into your vehicle’s diagnostic port. Having a grasp of DTCs can prove invaluable for both drivers and fleet managers alike.

Understanding DTCs is essential for anyone involved in vehicle maintenance, from individual car owners to fleet managers. These codes provide a standardized way to identify and address vehicle malfunctions, leading to more efficient repairs and reduced downtime. According to a study by the National Institute for Automotive Service Excellence (ASE), accurate diagnostics using DTCs can reduce repair times by up to 40%.

1.2 The Role of OBD Systems

The on-board diagnostics (OBD) system is the brain behind DTC generation. Whenever a fault is detected, the OBD system diagnoses the issue and displays the DTC through visible warnings, such as the check engine light. It also enables external devices, like OBD scanners, to communicate with the vehicle’s onboard computer system.

1.3 Evolution of OBD Standards: OBD-I to OBD-II

Over the years, OBD interfaces have evolved. Early versions, classified as OBD-I, varied significantly between manufacturers. Today, two main standards are used to read DTCs:

- OBD-II: Best suited for light- and medium-duty vehicles.

- J1939: Ideal for heavy-duty vehicles and heavy equipment.

The introduction of OBD-II brought a standardized DTC list with codes common to all manufacturers, thanks to the Society of Automotive Engineers (SAE). While OBD-II is widely used, manufacturer-specific DTCs still exist, supplementing the universal codes when necessary. These manufacturer-specific codes, however, often require a mechanic for interpretation.

1.4 OBD-II vs. J1939 Compliance

Determining whether your vehicle is OBD-II or J1939 compliant is essential for accurate diagnostics.

- OBD-II Compliance: Cars and light trucks built and sold in the United States after January 1, 1996, are required to be OBD-II equipped.

- J1939 Compliance: Most diesel engine manufactured vehicles or equipment are J1939 compliant and is the industry standard for most heavy-duty trucks and buses.

If unsure, consult your vehicle manual, research online, or check with your dealership for confirmation.

OBD-II Port

OBD-II Port

1.5 Standardized vs. Manufacturer-Specific Codes

The DTC list created by the Society of Automotive Engineers (SAE) standardized codes are common to all manufacturers. However, manufacturers may create their own DTCs to supplement the list of universal codes if the vehicle requires it. More often than not these manufacturer-specific codes are difficult to interpret without a mechanic.

2. Decoding OBD-II DTCs: A Comprehensive Guide

Understanding the anatomy of an OBD-II DTC is crucial for accurate diagnostics. These codes consist of five characters, each providing specific information about the vehicle’s problem.

2.1 Anatomy of a DTC: The Five Characters

DTC codes are five characters long. Each character in the DTC provides a different piece of information about the vehicle’s problem.

The first character is always a letter, indicating the control system with the issue:

- P (Powertrain): Refers to the engine, transmission, fuel system, and associated accessories.

- C (Chassis): Relates to mechanical systems outside the passenger compartment, such as steering, suspension, and braking.

- B (Body): Pertains to parts mainly found in the passenger compartment area.

- U (Network): Indicates issues with the vehicle’s onboard computers and related systems.

The second character is a digit, typically 0 or 1, showing whether the code is standardized:

- 0: Indicates a generic, standardized SAE (Society of Automotive Engineers) code adopted by all cars following the OBD-II standard.

- 1: Indicates a vehicle manufacturer-specific code, unique to a specific car make or model and typically less common.

- 2 or 3: Rarer and dependent on the preceding letter, usually indicating a manufacturer-specific code.

The third character, a digit from 1 to 8, reveals the subsystem at fault:

- 1: Fuel or air metering system.

- 2: Fuel or air metering injection system.

- 3: Ignition system.

- 4: Emissions system.

- 5: Vehicle speed controls and idle control system.

- 6: Computer output circuit.

- 7 and 8: Transmission-related issues.

The fourth and fifth characters, read together as a two-digit number between 0 and 99, form the specific fault index, identifying the exact vehicle issue. If unsure about a code’s meaning, consult your vehicle manufacturer or manual.

2.2 The First Character: Identifying the Control System

The first character of a DTC specifies which control system is experiencing the issue. Each letter represents a different area of the vehicle:

- P (Powertrain): This indicates that the problem lies within the engine, transmission, fuel system, or related accessories.

- C (Chassis): This signifies that the issue is related to mechanical systems outside the passenger compartment, such as steering, suspension, or braking.

- B (Body): This points to problems with components mainly located in the passenger compartment area.

- U (Network): This denotes issues with the vehicle’s onboard computers and related systems.

2.3 The Second Character: Standardized or Manufacturer-Specific?

The second character of a DTC reveals whether the code is standardized or specific to the vehicle manufacturer:

- 0: This indicates that the code is a generic, standardized SAE (Society of Automotive Engineers) code. Generic codes are adopted by all cars that follow the OBD-II standard.

- 1: This signifies that the code is vehicle manufacturer-specific. These codes are unique to a specific car make or model and are typically less common. Codes with “2” or “3” in this position are less frequent and generally indicate manufacturer-specific issues as well.

2.4 The Third Character: Pinpointing the Subsystem

The third character of a DTC, ranging from 1 to 8, identifies the specific subsystem at fault:

- 1: This refers to the fuel or air metering system.

- 2: This indicates the fuel or air metering injection system.

- 3: This points to the ignition system.

- 4: This signifies the emissions system.

- 5: This relates to the vehicle speed controls and idle control system.

- 6: This indicates the computer output circuit.

- 7 and 8: These suggest that the issue is transmission-related.

2.5 The Fourth and Fifth Characters: The Specific Fault Index

The fourth and fifth characters of a DTC are read together as a two-digit number between 0 and 99, forming the specific fault index. These characters pinpoint the exact issue within the identified subsystem.

Together, these five characters provide a comprehensive overview of the problem, enabling technicians and vehicle owners to accurately diagnose and address the issue. Consulting the vehicle manufacturer’s manual or a reliable online database can provide detailed explanations of each code.

3. Interpreting DTCs: Real-World Examples

Understanding how to interpret DTCs can help you diagnose vehicle issues effectively. By breaking down the codes, you can gain insights into the specific problems your vehicle is experiencing.

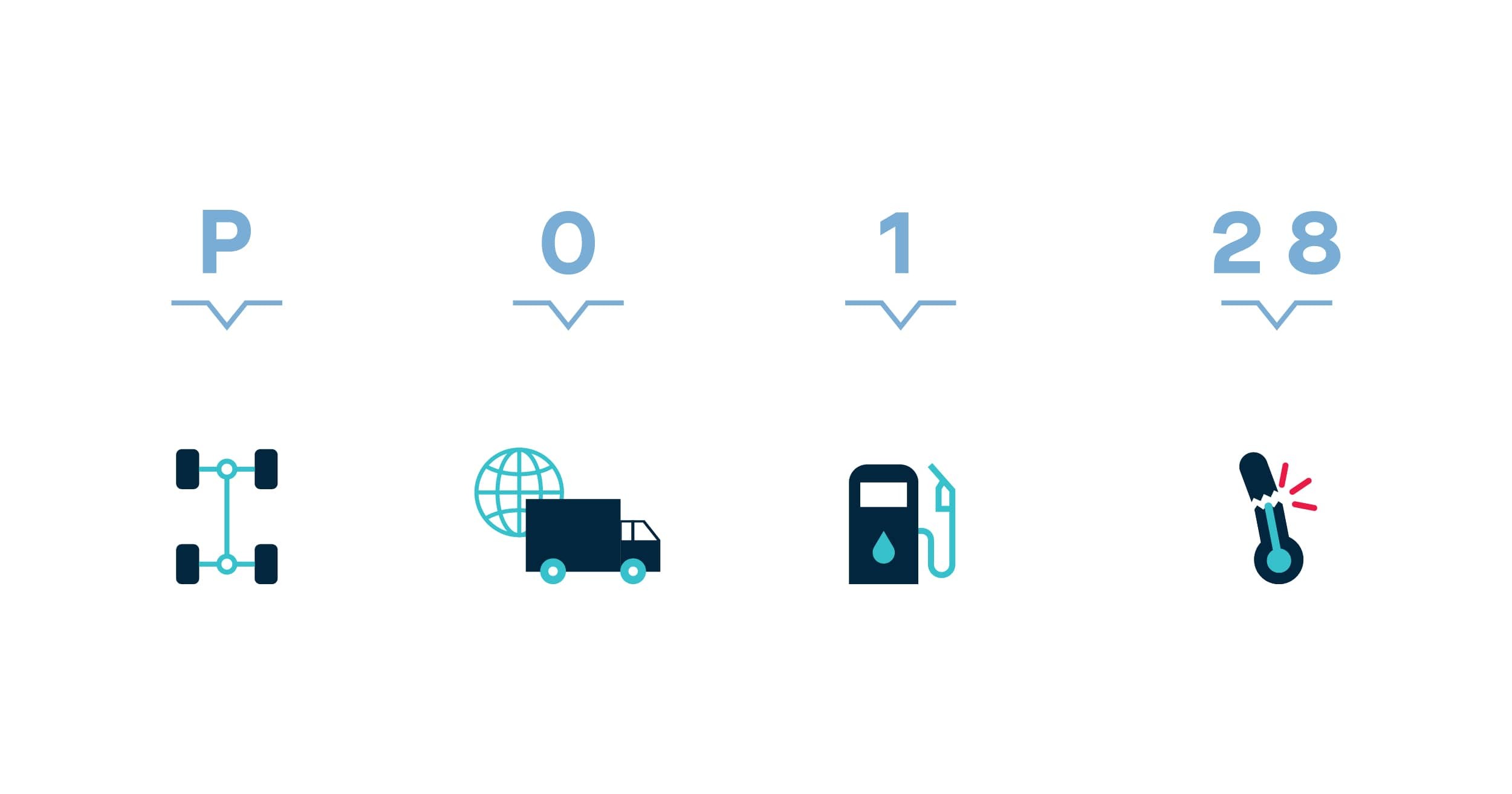

3.1 Decoding a Sample DTC: P0128

Consider the DTC P0128, which refers to an issue with the engine coolant temperature being below the thermostat regulating temperature. Here’s how to interpret it:

- The first letter, P, indicates the issue lies in the powertrain.

- The second character, 0, signifies that the code is not manufacturer-specific, meaning it is a standardized code interpretable according to SAE definitions.

- The third character, 1, reveals the issue is specifically within the fuel and air metering subsystem.

- The last two digits, 28, form the specific fault index.

Based on this, P0128 clearly points to a problem with the engine coolant temperature not reaching the thermostat’s regulating temperature.

3.2 Common DTCs and Their Meanings

Several DTCs are more likely to appear than others. Here are a few common examples:

- P0442: A small system leak in a vehicle’s evaporative emission control system.

- P0606: A malfunction in the powertrain control module (PCM), also known as the engine control module (ECM).

- P0101: A fault in the mass air flow (MAF) sensor or circuit.

- P0110: A malfunction in the intake air temperature sensor circuit.

- P0500: A vehicle speed sensor malfunction.

- P0706: A fault in the transmission range sensor circuit range.

While DTCs are useful for identifying a vehicle’s malfunction, they don’t explain why the malfunction occurred. Further diagnosis by a mechanic is necessary to identify and address the cause of the issue.

3.3 Why DTCs Aren’t Always Enough

DTCs are useful in identifying a vehicle’s malfunction, but they are not a way to decipher why the malfunction occurred. A vehicle needs to be further diagnosed by a mechanic to identify and address the cause of the issue.

4. J1939 DTCs: Understanding Heavy-Duty Vehicle Diagnostics

For heavy-duty vehicles, the J1939 standard is used for diagnostic trouble codes. These codes contain specific fields that provide detailed information about the fault being reported.

4.1 Structure of a J1939 DTC

A J1939 DTC contains four fields that relay information about the fault being reported by DTC. These fields are:

- Suspect Parameter Number (SPN): Represents the SPN with error. Every defined SPN can be used in a DTC.

- Failure Mode Identifier (FMI): Represents the nature and type of error that occurred, e.g., value range violation (high or low), sensor short-circuits, incorrect update rate, calibration error.

- Occurrence Counter (OC): A counter that counts the occurrence of the error condition for each SPN and stores this even when the error is no longer active.

- SPN Conversion Method (CM): Defines the byte alignment within the DTC. The value “0” represents the method shown in graphic “Structure of a DTC”. If CM has the value “1”, a distinction must be made between three previously valid methods; this must be known for the system.

4.2 Key Fields in J1939 DTCs

Each field in a J1939 DTC provides specific information:

- Suspect Parameter Number (SPN): Indicates the specific component or system with the error. Every defined SPN can be used in a DTC.

- Failure Mode Identifier (FMI): Describes the nature and type of error, such as value range violations (high or low), sensor short-circuits, incorrect update rates, or calibration errors.

- Occurrence Counter (OC): Tracks the number of times the error condition has occurred for each SPN, even when the error is no longer active.

- SPN Conversion Method (CM): Defines the byte alignment within the DTC.

Understanding these fields allows for a more detailed and accurate diagnosis of issues in heavy-duty vehicles.

4.3 How J1939 Differs from OBD-II

J1939 is tailored for the complex systems and diagnostics of heavy-duty vehicles, while OBD-II is designed for light- and medium-duty vehicles. The structure and fields within J1939 DTCs provide more granular information, which is essential for maintaining and repairing heavy machinery.

5. DTC Scan Tools: Choosing the Right Equipment

Having the right tools to read and interpret DTCs is essential for effective vehicle maintenance and diagnostics. Several options are available, ranging from basic OBD-II scanners to advanced fleet management solutions.

5.1 Standalone OBD-II Scanners

Scanners that read DTCs, known as OBD-II scanners, are widely available for purchase. These tools can range from basic models that only read and clear codes to more advanced versions with additional features like live data streaming and freeze frame data.

5.2 Fleet Management Solutions with DTC Tools

For fleet managers responsible for numerous vehicles, manually checking each vehicle every time the check engine light turns on can be inefficient. Fleet management solutions with integrated DTC tools offer a more streamlined approach.

5.3 How Telematics Solutions Simplify DTC Management

Telematics solutions, like the ones offered by Samsara, include maintenance tools that make identifying DTCs fast and easy. Vehicle gateways plug directly into the vehicle’s OBD-II port and send vehicle-related data—including DTCs—to the cloud. This means that if a DTC occurs, it automatically populates in your dashboard, and you can choose to be notified via an alert.

In the event that several of your fleet vehicles experience DTC issues, a telematics solution with a DTC tool can help you quickly identify the issue, enabling you to schedule maintenance as needed.

6. Leveraging MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for DTC Solutions

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers specialized tools and information to assist with diagnosing and addressing DTCs in Mercedes-Benz vehicles. By using our resources, you can efficiently manage vehicle maintenance and repairs.

6.1 Diagnostic Tools Offered by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides a range of diagnostic tools tailored for Mercedes-Benz vehicles. These tools allow you to accurately read and interpret DTCs, enabling you to identify issues quickly and efficiently. Our offerings include:

- OBD-II Scanners: Compatible with Mercedes-Benz vehicles, these scanners provide access to DTCs and live data.

- Professional Diagnostic Software: Advanced software solutions that offer in-depth diagnostics, including manufacturer-specific codes and system analysis.

- Handheld Diagnostic Devices: Portable devices for on-the-go diagnostics, perfect for both professional technicians and vehicle owners.

6.2 How to Use Our Resources for DTC Interpretation

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a comprehensive database of DTCs specific to Mercedes-Benz vehicles. This resource helps you understand the meaning of each code, potential causes, and recommended solutions. Our step-by-step guides and expert advice can assist you in diagnosing and resolving vehicle issues.

6.3 Benefits of Using Our Services for Mercedes-Benz Diagnostics

By utilizing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for your Mercedes-Benz diagnostics, you can experience numerous benefits:

- Accurate Diagnostics: Our tools and resources provide precise DTC readings and interpretations, ensuring accurate diagnostics.

- Time and Cost Savings: By quickly identifying issues, you can reduce downtime and repair costs.

- Expert Support: Our team of experienced technicians offers expert support and guidance, helping you resolve complex issues.

- Vehicle Longevity: Regular diagnostics and maintenance based on accurate DTC information can extend the life of your Mercedes-Benz.

7. Step-by-Step Guide to Diagnosing DTCs on Mercedes-Benz

Diagnosing DTCs on your Mercedes-Benz can be a straightforward process with the right tools and guidance. Here’s a step-by-step guide to help you through the process.

7.1 Gathering Necessary Tools and Equipment

Before you begin, ensure you have the necessary tools and equipment:

- OBD-II Scanner: A compatible scanner for Mercedes-Benz vehicles.

- Mercedes-Benz Repair Manual: Provides specific information about your vehicle model.

- Basic Hand Tools: Wrenches, screwdrivers, and pliers for minor repairs.

- Safety Gear: Gloves and safety glasses to protect yourself.

7.2 Connecting the OBD-II Scanner

- Locate the OBD-II Port: Typically found under the dashboard on the driver’s side.

- Plug in the Scanner: Connect the OBD-II scanner to the port.

- Turn on the Ignition: Turn the key to the “on” position without starting the engine.

- Power on the Scanner: Follow the scanner’s instructions to power it on.

7.3 Reading and Recording DTCs

- Select “Read Codes”: Use the scanner’s menu to select the option to read diagnostic trouble codes.

- Record the Codes: Write down all the DTCs that appear on the scanner’s screen.

- Note Freeze Frame Data: If available, record any freeze frame data, which provides a snapshot of the vehicle’s conditions when the code was triggered.

7.4 Interpreting the DTCs

- Consult the Repair Manual: Use your Mercedes-Benz repair manual to look up the meaning of each DTC.

- Use Online Resources: Visit MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for detailed explanations and potential causes of the codes.

- Analyze the Data: Determine the potential issues based on the DTCs and any freeze frame data.

7.5 Troubleshooting and Repair

- Start with Simple Fixes: Check for loose gas caps, faulty sensors, or damaged wires.

- Perform Diagnostic Tests: Use the repair manual to guide you through specific diagnostic tests related to the DTCs.

- Replace Faulty Components: If a component is identified as faulty, replace it according to the repair manual’s instructions.

- Clear the Codes: After completing the repairs, use the OBD-II scanner to clear the DTCs.

- Test Drive: Take the vehicle for a test drive to ensure the issue is resolved and the check engine light does not reappear.

By following these steps, you can effectively diagnose and address DTCs on your Mercedes-Benz, ensuring it remains in optimal condition.

8. Advanced Diagnostic Techniques for Mercedes-Benz

For more complex issues, advanced diagnostic techniques may be necessary to accurately pinpoint the problem. These techniques often require specialized tools and expertise.

8.1 Using Advanced Diagnostic Software

Advanced diagnostic software provides in-depth analysis of your Mercedes-Benz’s systems, offering more detailed information than basic OBD-II scanners. These software solutions can access manufacturer-specific codes, perform component testing, and provide live data streams.

8.2 Performing Component-Level Testing

Component-level testing involves testing individual components to determine if they are functioning correctly. This can include testing sensors, actuators, and electronic control units (ECUs). Using a multimeter, oscilloscope, and other specialized tools can help you assess the performance of these components.

8.3 Analyzing Live Data Streams

Analyzing live data streams involves monitoring the real-time performance of various systems in your Mercedes-Benz. This can help you identify intermittent issues, performance bottlenecks, and other problems that may not trigger a DTC. Advanced diagnostic software and scanners often provide live data streaming capabilities.

8.4 When to Seek Professional Help

While many DTCs can be diagnosed and resolved with basic tools and knowledge, some issues require professional expertise. If you are uncomfortable performing certain diagnostic tests or repairs, or if the issue persists after troubleshooting, it’s best to seek help from a qualified Mercedes-Benz technician.

9. Preventing DTCs: Regular Maintenance Tips

Preventing DTCs is crucial for maintaining the health and longevity of your Mercedes-Benz. Regular maintenance can help you avoid many common issues that trigger diagnostic trouble codes.

9.1 Regular Vehicle Inspections

Regular vehicle inspections are essential for identifying potential problems before they escalate. Check fluid levels, tire pressure, brakes, lights, and other critical components regularly.

9.2 Following the Mercedes-Benz Maintenance Schedule

Adhering to the recommended maintenance schedule for your Mercedes-Benz can help prevent many common issues. This includes regular oil changes, filter replacements, spark plug replacements, and other routine services.

9.3 Monitoring Vehicle Performance

Pay attention to how your Mercedes-Benz is performing. Unusual noises, vibrations, or changes in fuel economy can indicate underlying issues that need to be addressed.

9.4 Proper Fluid Maintenance

Maintaining proper fluid levels and using the correct type of fluids is crucial for the health of your Mercedes-Benz. This includes engine oil, coolant, brake fluid, power steering fluid, and transmission fluid.

9.5 Addressing Issues Promptly

If you notice any issues with your Mercedes-Benz, address them promptly. Ignoring small problems can lead to more significant and costly repairs down the road.

10. Future Trends in OBD and DTC Technology

The field of OBD and DTC technology is constantly evolving, with new advancements and innovations emerging regularly. Staying informed about these trends can help you better understand and maintain your vehicle.

10.1 Advancements in OBD-III and Beyond

OBD-III and future OBD systems are expected to offer more advanced diagnostic capabilities, including remote diagnostics, predictive maintenance, and enhanced data analysis. These systems will be able to communicate directly with manufacturers and service providers, providing real-time alerts and diagnostic information.

10.2 The Role of Artificial Intelligence (AI) in Diagnostics

Artificial intelligence (AI) is playing an increasingly important role in vehicle diagnostics. AI-powered diagnostic tools can analyze vast amounts of data to identify patterns, predict failures, and provide more accurate and efficient diagnostic information.

10.3 Integration with Smart Devices

OBD technology is increasingly integrating with smart devices, such as smartphones and tablets. This allows vehicle owners to access diagnostic information, monitor vehicle performance, and receive maintenance alerts directly on their devices.

10.4 Cybersecurity Considerations

As vehicles become more connected and reliant on electronic systems, cybersecurity is becoming an increasingly important consideration. Protecting vehicle systems from cyber threats is essential for ensuring safety and reliability.

FAQ: Decoding DTCs and Mercedes-Benz Diagnostics

What is the most common reason for a check engine light to come on in a Mercedes-Benz?

The check engine light can illuminate for various reasons, such as a loose gas cap, faulty oxygen sensor, or issues with the catalytic converter.

How do I find the right OBD-II scanner for my Mercedes-Benz model?

Look for scanners that are specifically compatible with Mercedes-Benz vehicles, ensuring they support the necessary protocols and access manufacturer-specific codes.

Can I clear a DTC myself, and is it safe to do so?

Yes, you can clear a DTC using an OBD-II scanner, but it’s essential to diagnose and address the underlying issue first to prevent it from recurring.

What does a manufacturer-specific DTC indicate?

A manufacturer-specific DTC indicates an issue unique to your Mercedes-Benz model, often requiring specialized knowledge and tools for diagnosis.

How often should I perform a diagnostic scan on my Mercedes-Benz?

Perform a diagnostic scan whenever the check engine light comes on or if you notice unusual performance issues. Regular scans during maintenance checks are also beneficial.

What are the key differences between OBD-II and J1939 diagnostic systems?

OBD-II is typically used for light- and medium-duty vehicles, while J1939 is designed for heavy-duty vehicles and equipment, with different protocols and data structures.

Where can I find reliable information on Mercedes-Benz specific DTCs?

Visit MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for a comprehensive database of Mercedes-Benz specific DTCs, along with expert advice and resources.

How can advanced diagnostic software improve my Mercedes-Benz maintenance?

Advanced software provides in-depth system analysis, component testing, and live data streams, enabling more accurate and efficient diagnostics.

What maintenance steps can help prevent DTCs from appearing?

Regular vehicle inspections, adherence to the maintenance schedule, monitoring vehicle performance, and proper fluid maintenance are crucial for preventing DTCs.

When should I seek professional help for diagnosing a DTC on my Mercedes-Benz?

Seek professional help if you are uncomfortable performing diagnostic tests, if the issue persists after troubleshooting, or if you encounter complex problems requiring specialized expertise.

Understanding DTCs and utilizing the right diagnostic tools are essential for maintaining your Mercedes-Benz. By following the tips and guidance provided by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, you can ensure your vehicle remains in optimal condition.

Don’t let DTCs keep you in the dark. Contact us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, located at 789 Oak Avenue, Miami, FL 33101, United States, or call us on Whatsapp at +1 (641) 206-8880 for expert assistance with diagnostics, unlocking hidden features, and professional repair advice. Let us help you keep your Mercedes-Benz running smoothly!