The OBD2 interface is your gateway to understanding and optimizing your Mercedes-Benz. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide expert insights and tools to help you leverage this powerful diagnostic system for enhanced vehicle performance and maintenance, offering a complete solution to access and interpret vehicle data for informed decisions and proactive maintenance. Unlock hidden functionalities and customized performance with our comprehensive OBD2 solutions, supported by advanced diagnostic tools and expert guidance.

Contents

- 1. Understanding the Basics of the OBD2 Interface

- 1.1. What Exactly is the OBD2 Interface?

- 1.2. Key Components of the OBD2 System

- 1.3. How Does OBD2 Work in Mercedes-Benz Vehicles?

- 1.4. Benefits of Using the OBD2 Interface

- 2. OBD2 History and Evolution

- 2.1. Origins of OBD2

- 2.2. Key Milestones in OBD2 Development

- 2.3. The Role of OBD2 in Emission Control

- 2.4. Future Trends in OBD Technology

- 3. Essential OBD2 Standards and Protocols

- 3.1. Overview of OBD2 Standards

- 3.2. SAE J1962: The OBD2 Connector Standard

- 3.3. ISO 15765-4: OBD2 and CAN Bus

- 3.4. Key Protocols: CAN, KWP2000, and More

- 4. Deciphering OBD2 Modes and Parameter IDs (PIDs)

- 4.1. Introduction to OBD2 Modes (Services)

- 4.2. Understanding OBD2 Parameter IDs (PIDs)

- 4.3. Common OBD2 PIDs and Their Meanings

- 4.4. Using an OBD2 PID Overview Tool

- 5. Step-by-Step Guide to Logging and Decoding OBD2 Data

- 5.1. Selecting the Right OBD2 Data Logger

- 5.2. Configuring Your OBD2 Data Logger

- 5.3. Connecting to the Vehicle’s OBD2 Port

- 5.4. Capturing OBD2 Data

- 5.5. Decoding Raw OBD2 Data

- 5.6. Using DBC Files for Decoding

- 6. Advanced OBD2 Techniques: Multi-Frame Communication and ISO-TP

- 6.1. Understanding Multi-Frame Communication

- 6.2. The Role of ISO-TP (ISO 15765-2)

- 6.3. Example 1: Retrieving the Vehicle Identification Number (VIN)

- 6.4. Example 2: Requesting Diagnostic Trouble Codes (DTCs)

- 7. Practical Applications and Use Cases for OBD2 Data Logging

- 7.1. Monitoring Fuel Efficiency

- 7.2. Improving Driving Habits

- 7.3. Vehicle Diagnostics

- 7.4. Predictive Maintenance

- 7.5. Real-Time Car Diagnostics

- 7.6. Vehicle Black Box Logging

- 8. Navigating Common Challenges and Troubleshooting OBD2 Issues

- 8.1. Common OBD2 Connection Problems

- 8.2. Dealing with Incompatible Devices

- 8.3. Interpreting Error Codes and Data

- 8.4. Addressing Data Accuracy Issues

- 9. Expert Tips for Maximizing the Potential of Your Mercedes OBD2 Interface

- 9.1. Choosing the Right OBD2 Scanner for Your Needs

- 9.2. Regularly Monitoring Key Parameters

- 9.3. Leveraging OBD2 for Performance Tuning

- 9.4. Using OBD2 for Preventative Maintenance

- 9.5. Utilizing Online Resources and Communities

- 10. Frequently Asked Questions (FAQs) About the OBD2 Interface

1. Understanding the Basics of the OBD2 Interface

The On-Board Diagnostics II (OBD2) interface is a standardized system used in most modern vehicles, including Mercedes-Benz, to monitor and report on various vehicle parameters. Introduced in the mid-1990s, OBD2 provides technicians and vehicle owners with access to a wealth of diagnostic information, making it easier to identify and address issues. This standard ensures that regardless of the manufacturer, certain diagnostic data is accessible in a consistent format, allowing for universal diagnostic tools to be effective across different makes and models.

1.1. What Exactly is the OBD2 Interface?

The OBD2 interface serves as your car’s built-in self-diagnostic system. It’s a standardized protocol that allows you to extract diagnostic trouble codes (DTCs) and real-time data through the OBD2 connector. According to the Society of Automotive Engineers (SAE), the OBD2 standard mandates a specific connector and a set of diagnostic parameters that all compliant vehicles must support.

1.2. Key Components of the OBD2 System

- OBD2 Connector: A 16-pin connector, usually located under the dashboard, provides physical access to the vehicle’s diagnostic system.

- Diagnostic Trouble Codes (DTCs): Standardized codes that indicate specific issues or malfunctions detected by the vehicle’s computer.

- Parameter IDs (PIDs): Identifiers for specific data points, such as engine speed, coolant temperature, and fuel consumption.

- Diagnostic Tools: Scanners and software used to read DTCs and access real-time data from the OBD2 interface.

1.3. How Does OBD2 Work in Mercedes-Benz Vehicles?

In Mercedes-Benz vehicles, the OBD2 interface allows technicians and owners to access a wide range of diagnostic data. This includes information about the engine, transmission, emissions system, and other critical components. By connecting an OBD2 scanner to the diagnostic port, users can read DTCs, monitor real-time data, and perform various diagnostic tests. The Electronic Control Units (ECUs) within the Mercedes-Benz communicate through the OBD2 port, providing a detailed overview of the vehicle’s operational status.

1.4. Benefits of Using the OBD2 Interface

- Early Detection of Problems: Identify potential issues before they lead to major repairs.

- Cost Savings: Perform basic diagnostics and maintenance tasks yourself, reducing trips to the mechanic.

- Performance Monitoring: Track key performance parameters to optimize driving and vehicle health.

- Informed Decision-Making: Make educated decisions about repairs and maintenance based on accurate diagnostic data.

- Unlock Hidden Features: With advanced tools, access and customize various vehicle settings and functionalities.

2. OBD2 History and Evolution

The history of OBD2 is rooted in the need for standardized emission control and diagnostics, evolving from basic systems to sophisticated interfaces that offer extensive vehicle data.

2.1. Origins of OBD2

The journey began in California, where the California Air Resources Board (CARB) mandated OBD systems in all new cars from 1991 onwards for emission control. This requirement led to the development of the OBD2 standard, recommended by the Society of Automotive Engineers (SAE), standardizing DTCs and the OBD connector across different manufacturers using SAE J1962.

2.2. Key Milestones in OBD2 Development

- 1996: OBD2 became mandatory in the USA for cars and light trucks.

- 2001: Required in the EU for gasoline cars.

- 2003: Required in the EU for diesel cars (EOBD).

- 2005: OBD2 required in the US for medium-duty vehicles.

- 2008: US cars required to use ISO 15765-4 (CAN) as the OBD2 basis.

- 2010: OBD2 required in US heavy-duty vehicles.

2.3. The Role of OBD2 in Emission Control

Initially designed for emission control and testing, OBD2 monitors various components related to the vehicle’s emissions system, ensuring compliance with environmental regulations. By tracking the performance of sensors and systems that affect emissions, OBD2 helps identify issues that could lead to increased pollution.

2.4. Future Trends in OBD Technology

The future of OBD2 includes several key trends:

- OBD3: Adding telematics to vehicles for remote diagnostics and emissions testing. This involves using a radio transponder to transmit vehicle identification number (VIN) and DTCs via WiFi to a central server for checks.

- Alternatives like WWH-OBD and OBDonUDS: These aim to streamline and enhance OBD communication by leveraging the UDS protocol as the basis, offering richer data and improved lower-layer protocols.

- Challenges in Electric Vehicles: Electric vehicles are not always required to support OBD2, with many utilizing OEM-specific UDS communication, making data decoding difficult without reverse engineering.

3. Essential OBD2 Standards and Protocols

OBD2 standards specify the OBD2 connector, lower-layer protocols, OBD2 parameter IDs (PID), and more, facilitating standardized communication.

3.1. Overview of OBD2 Standards

OBD2, being a higher-layer protocol, functions like a language, while CAN (Controller Area Network) acts as a method for communication, similar to a phone line. This is comparable to other CAN-based higher-layer protocols like J1939, CANopen, and NMEA 2000. The OBD2 standards are detailed in documents such as SAE J1979 and ISO 15031-5, which define the diagnostic services, PIDs, and data formats.

3.2. SAE J1962: The OBD2 Connector Standard

The SAE J1962 standard defines the physical OBD2 connector, a 16-pin interface that allows access to data from the car. Key aspects include:

- Location: Usually near the steering wheel.

- Pin 16: Supplies battery power.

- Pinout: Depends on the communication protocol.

- Common Protocol: CAN bus, with pins 6 (CAN-H) and 14 (CAN-L) typically connected.

3.3. ISO 15765-4: OBD2 and CAN Bus

ISO 15765-4, also known as Diagnostics over CAN (DoCAN), standardizes the CAN interface for test equipment, focusing on the physical, data link, and network layers:

- Bit-rate: Must be either 250K or 500K.

- CAN IDs: Can be 11-bit or 29-bit.

- CAN IDs: Specific CAN IDs used for OBD requests/responses.

- Data Length: Diagnostic CAN frame data length must be 8 bytes.

- Cable Length: OBD2 adapter cable must be max 5 meters.

3.4. Key Protocols: CAN, KWP2000, and More

While CAN bus is the predominant lower-layer protocol for OBD2, older cars may use other protocols:

- ISO 15765 (CAN bus): Mandatory in US cars since 2008.

- ISO 14230-4 (KWP2000): Common for 2003+ cars, especially in Asia.

- ISO 9141-2: Used in EU, Chrysler, and Asian cars in 2000-04.

- SAE J1850 (VPW): Mostly used in older GM cars.

- SAE J1850 (PWM): Mostly used in older Ford cars.

Understanding these protocols helps in diagnosing and communicating with a wide range of vehicles, ensuring compatibility and effective data retrieval.

4. Deciphering OBD2 Modes and Parameter IDs (PIDs)

To effectively use the OBD2 interface, understanding its modes and Parameter IDs (PIDs) is crucial. These elements allow users to request and interpret data from a vehicle’s diagnostic system.

4.1. Introduction to OBD2 Modes (Services)

OBD2 modes, also known as diagnostic services, are commands that tell the vehicle’s computer what type of information to provide. There are 10 standardized OBD2 modes:

- $01 – Show current data: Displays real-time data such as engine speed, coolant temperature, and oxygen sensor values.

- $02 – Show freeze frame data: Displays data captured when a DTC was set, providing a snapshot of conditions at the time of the fault.

- $03 – Show stored Diagnostic Trouble Codes (DTCs): Retrieves a list of current DTCs stored in the vehicle’s computer.

- $04 – Clear Diagnostic Trouble Codes (DTCs): Erases stored DTCs and resets the Malfunction Indicator Lamp (MIL).

- $05 – Oxygen sensor monitoring test results: Displays results from oxygen sensor tests.

- $06 – Non-continuously monitored systems test results: Shows test results for systems that are not continuously monitored.

- $07 – Show pending DTCs: Displays DTCs that have been detected during the current or last driving cycle but have not yet triggered the MIL.

- $08 – Control operation of on-board component: Allows control of specific on-board components for testing purposes.

- $09 – Request vehicle information: Requests vehicle information such as the VIN, calibration ID, and calibration verification number.

- $0A – Permanent DTCs: Retrieves DTCs that cannot be cleared by any means other than fixing the underlying problem.

Vehicles do not have to support all OBD2 modes, and they may support additional OEM-specific modes.

4.2. Understanding OBD2 Parameter IDs (PIDs)

Within each OBD2 mode, Parameter IDs (PIDs) are used to request specific data points. For example, mode $01 contains around 200 standardized PIDs for real-time data such as speed, RPM, and fuel level. However, not all vehicles support every PID in a given mode; most support only a subset.

One special PID is mode $01 PID $00, which any emissions-related ECU must support if it supports any OBD2 services. Responding to this PID, the vehicle’s ECU indicates whether it supports PIDs $01-$20, making it a fundamental compatibility test. PIDs $20, $40, $60, and so on can be used to determine support for the remaining mode $01 PIDs.

4.3. Common OBD2 PIDs and Their Meanings

Here are some common OBD2 PIDs and their meanings:

- $0D – Vehicle Speed: Indicates the vehicle’s current speed in km/h or mph.

- $0C – Engine RPM: Shows the engine’s current revolutions per minute.

- $0B – Intake Manifold Absolute Pressure: Measures the pressure in the intake manifold.

- $04 – Calculated Engine Load Value: Represents the percentage of maximum engine load.

- $05 – Engine Coolant Temperature: Displays the temperature of the engine coolant.

4.4. Using an OBD2 PID Overview Tool

To assist in decoding OBD2 data into physical values, tools like the OBD2 PID overview tool can be invaluable. These tools help construct OBD2 request frames and dynamically decode the responses, making it easier to interpret the data received from the vehicle.

5. Step-by-Step Guide to Logging and Decoding OBD2 Data

Logging and decoding OBD2 data involves connecting to the vehicle’s diagnostic port, capturing the data, and interpreting it using appropriate tools and techniques.

5.1. Selecting the Right OBD2 Data Logger

Choosing the right OBD2 data logger is the first step. A suitable logger should:

- Support all relevant OBD2 protocols and modes.

- Have sufficient storage capacity for the data you intend to log.

- Be compatible with your vehicle’s communication standards.

- Offer user-friendly software for configuration and data analysis.

5.2. Configuring Your OBD2 Data Logger

Once you have an OBD2 data logger, configure it to capture the specific data you need. This involves:

- Setting the bit-rate: Determine the correct bit-rate (250K or 500K) for your vehicle.

- Identifying CAN IDs: Verify whether your vehicle uses 11-bit or 29-bit CAN IDs.

- Specifying PIDs: Select the PIDs you want to log, based on the data you need to monitor.

5.3. Connecting to the Vehicle’s OBD2 Port

Connect the OBD2 data logger to the vehicle’s OBD2 port, typically located under the dashboard. Ensure the connection is secure to avoid data loss during logging.

5.4. Capturing OBD2 Data

Start the vehicle and initiate the data logging process. Monitor the data logger to ensure it is capturing data correctly. Let the logger run for the duration needed to capture all relevant data.

5.5. Decoding Raw OBD2 Data

After capturing the data, you’ll need to decode it to extract meaningful information. This involves converting raw hexadecimal values into physical units like km/h, RPM, or degrees Celsius. Tools like the OBD2 DBC file can assist in this process.

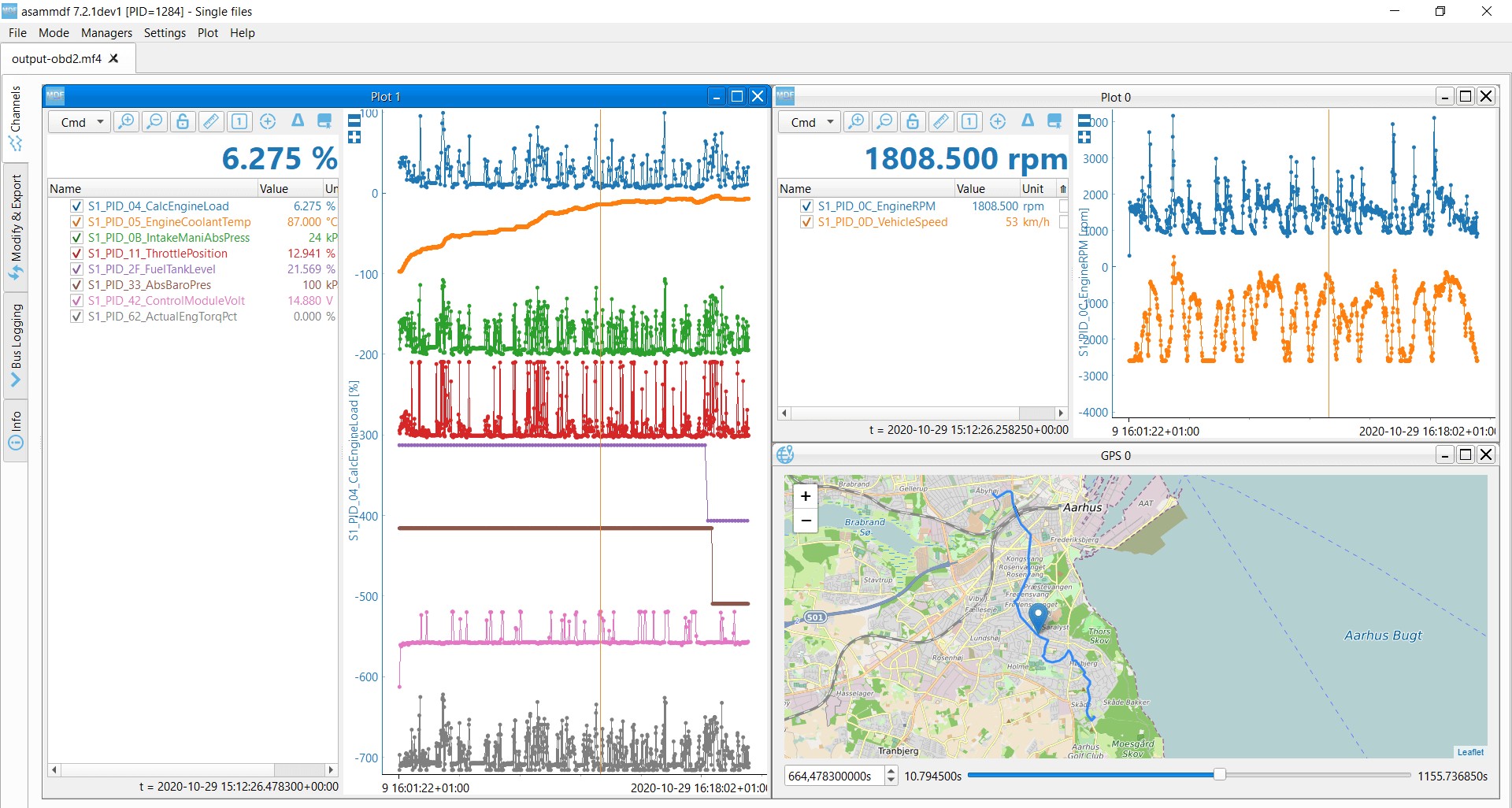

OBD2 data decoded visual plot asammdf CAN bus DBC file

OBD2 data decoded visual plot asammdf CAN bus DBC file

5.6. Using DBC Files for Decoding

DBC (CAN database) files contain the necessary information to decode raw CAN data, including OBD2 data. To use a DBC file:

- Import the DBC file into your CAN bus analysis software.

- Select the appropriate CAN IDs and signals.

- Apply the decoding rules specified in the DBC file to convert raw data into physical values.

This process makes the data human-readable and facilitates analysis.

6. Advanced OBD2 Techniques: Multi-Frame Communication and ISO-TP

Advanced OBD2 techniques, such as multi-frame communication and the use of ISO-TP, enable the transfer of larger data packets necessary for specific diagnostic requests.

6.1. Understanding Multi-Frame Communication

Multi-frame communication is used when the data to be transmitted exceeds the 8-byte limit of a single CAN frame. This requires segmentation, flow control, and reassembly of data packets, as specified by ISO 15765-2.

6.2. The Role of ISO-TP (ISO 15765-2)

ISO-TP (Transport Protocol) is crucial for multi-frame communication, enabling the transfer of larger payloads by breaking them into smaller segments. This protocol handles:

- Segmentation of data into multiple frames.

- Flow control to manage the transmission rate.

- Reassembly of frames into the complete message.

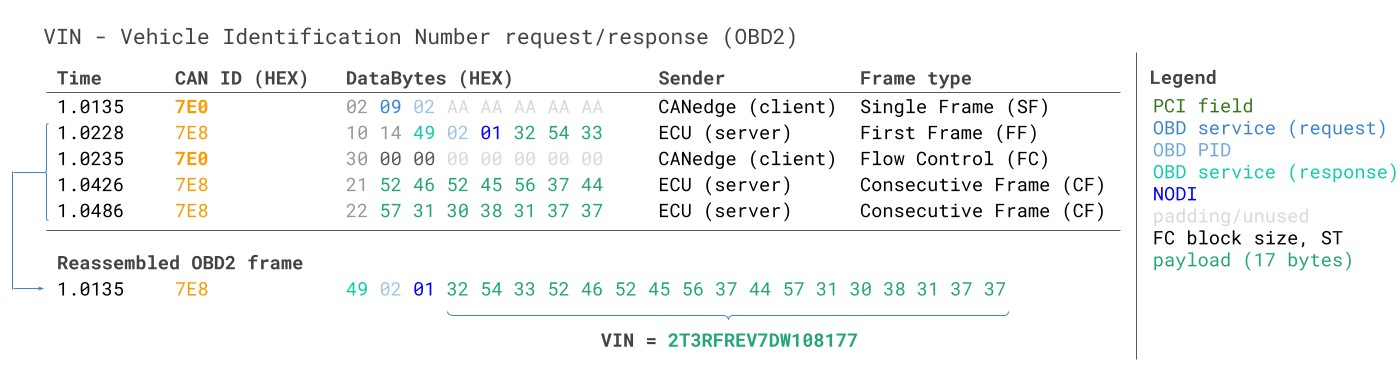

6.3. Example 1: Retrieving the Vehicle Identification Number (VIN)

The Vehicle Identification Number (VIN) often requires multi-frame communication because it exceeds the 8-byte limit. Here’s how to retrieve it:

- The tester tool sends a Single Frame request with the PCI field (0x02), request service identifier (0x09), and PID (0x02).

- The vehicle responds with a First Frame containing the PCI, length (0x014 = 20 bytes), mode (0x49, i.e., 0x09 + 0x40), and PID (0x02).

- Following the PID is the byte 0x01, which is the Number Of Data Items (NODI), in this case, 1.

- The remaining 17 bytes equal the VIN and can be translated from HEX to ASC.

VIN Vehicle Identification Number OBD2 Example multi-frame

VIN Vehicle Identification Number OBD2 Example multi-frame

6.4. Example 2: Requesting Diagnostic Trouble Codes (DTCs)

Requesting Diagnostic Trouble Codes (DTCs) can also involve multi-frame communication if more than a few DTCs are stored. The process involves:

- Sending a request using mode $03 to show stored DTCs.

- The ECU responds with the number of stored DTCs, each taking up 2 data bytes.

- If more than 2 DTCs are stored, multi-frame responses are necessary.

- The 2-byte DTC value is split into two parts: the first 2 bits define the category, and the remaining 14 bits define a 4-digit code.

7. Practical Applications and Use Cases for OBD2 Data Logging

OBD2 data logging has numerous practical applications, ranging from vehicle diagnostics to performance monitoring and predictive maintenance.

7.1. Monitoring Fuel Efficiency

By logging OBD2 data such as fuel consumption, engine load, and vehicle speed, you can monitor and optimize fuel efficiency. Analyzing this data can help identify driving habits that lead to higher fuel consumption and implement strategies to improve mileage.

7.2. Improving Driving Habits

OBD2 data can provide insights into driving habits, helping you identify and correct aggressive behaviors such as hard acceleration and braking. By monitoring parameters like throttle position and brake pressure, you can promote smoother, more efficient driving.

7.3. Vehicle Diagnostics

OBD2 data logging is invaluable for diagnosing vehicle issues. By capturing data before, during, and after a problem occurs, you can gain insights into the root cause and identify potential solutions.

7.4. Predictive Maintenance

Monitoring OBD2 data over time can help predict potential maintenance needs. By tracking parameters such as engine temperature, oil pressure, and battery voltage, you can identify trends that indicate impending issues and schedule maintenance proactively.

7.5. Real-Time Car Diagnostics

OBD2 interfaces facilitate real-time streaming of data, which is useful for diagnosing vehicle issues on the fly. This is particularly helpful for technicians who need to monitor various parameters while the vehicle is in operation.

7.6. Vehicle Black Box Logging

An OBD2 logger can serve as a “black box” for vehicles, recording data that can be used in the event of an accident or dispute. This data can provide valuable insights into the events leading up to the incident.

8. Navigating Common Challenges and Troubleshooting OBD2 Issues

While OBD2 provides valuable diagnostic information, users may encounter challenges. Knowing how to troubleshoot these issues ensures a smooth diagnostic process.

8.1. Common OBD2 Connection Problems

- Loose Connection: Ensure the OBD2 scanner is securely connected to the vehicle’s diagnostic port.

- Incorrect Protocol: Verify that the scanner supports the correct protocol for your vehicle (e.g., CAN, KWP2000).

- Faulty OBD2 Port: Check the OBD2 port for damage or corrosion.

8.2. Dealing with Incompatible Devices

- Check Compatibility: Before purchasing an OBD2 scanner, verify that it is compatible with your vehicle’s make, model, and year.

- Update Firmware: Keep your OBD2 scanner’s firmware updated to ensure it supports the latest protocols and PIDs.

- Use Adapters: In some cases, adapters may be available to bridge compatibility gaps between the scanner and the vehicle.

8.3. Interpreting Error Codes and Data

- Consult the Manual: Refer to your vehicle’s repair manual or online resources for detailed information on specific error codes.

- Use OBD2 Code Lookup Tools: Utilize online OBD2 code lookup tools to understand the meaning of error codes.

- Seek Professional Help: If you are unsure how to interpret error codes or data, consult a qualified mechanic.

8.4. Addressing Data Accuracy Issues

- Check Sensor Health: Ensure that the sensors providing data to the OBD2 system are functioning correctly.

- Verify Calibration: Verify that the OBD2 system is properly calibrated.

- Cross-Reference Data: Compare OBD2 data with other diagnostic information to ensure accuracy.

9. Expert Tips for Maximizing the Potential of Your Mercedes OBD2 Interface

To truly harness the power of your Mercedes OBD2 interface, consider these expert tips.

9.1. Choosing the Right OBD2 Scanner for Your Needs

Selecting the right OBD2 scanner can greatly enhance your diagnostic capabilities. Consider these factors:

- Functionality: Determine whether you need a basic code reader or a more advanced scanner with features like live data streaming and bi-directional control.

- Compatibility: Ensure that the scanner is compatible with your Mercedes-Benz model and year.

- User Interface: Choose a scanner with a user-friendly interface that is easy to navigate.

- Updates: Opt for a scanner that offers regular software updates to support new vehicles and features.

9.2. Regularly Monitoring Key Parameters

Regularly monitoring key parameters can help you identify potential issues before they escalate. Pay attention to:

- Engine Temperature: Watch for fluctuations that could indicate cooling system problems.

- Fuel Trims: Monitor fuel trims to detect fuel delivery issues.

- Oxygen Sensor Readings: Check oxygen sensor readings to ensure proper combustion.

- Battery Voltage: Keep an eye on battery voltage to identify charging system problems.

9.3. Leveraging OBD2 for Performance Tuning

The OBD2 interface can be used for performance tuning by adjusting various engine parameters. However, proceed with caution and consult with a qualified tuner to avoid damaging your vehicle.

9.4. Using OBD2 for Preventative Maintenance

OBD2 data can be used to guide preventative maintenance tasks. For example, monitoring oil temperature and pressure can help you determine the optimal oil change interval. Similarly, tracking coolant temperature can help you identify the need for cooling system maintenance.

9.5. Utilizing Online Resources and Communities

Take advantage of online resources and communities to learn more about OBD2 diagnostics and troubleshooting. Forums, online databases, and expert blogs can provide valuable insights and solutions to common problems.

10. Frequently Asked Questions (FAQs) About the OBD2 Interface

Here are some frequently asked questions about the OBD2 interface to help you better understand this powerful diagnostic tool.

Q1: What is the OBD2 interface?

The OBD2 interface is a standardized system used in vehicles to monitor and report on various parameters, allowing for diagnostics and performance monitoring.

Q2: Where is the OBD2 port located in my Mercedes-Benz?

The OBD2 port is typically located under the dashboard, near the steering wheel.

Q3: What types of data can I access through the OBD2 interface?

You can access a wide range of data, including engine speed, coolant temperature, fuel consumption, and diagnostic trouble codes (DTCs).

Q4: Can I clear Diagnostic Trouble Codes (DTCs) using an OBD2 scanner?

Yes, most OBD2 scanners allow you to clear DTCs, but it’s important to address the underlying issue first.

Q5: Is it safe to use an OBD2 scanner while driving?

It’s generally not recommended to use an OBD2 scanner while driving, as it can be distracting.

Q6: What is the difference between OBD2 and OBD1?

OBD2 is a standardized system, while OBD1 was manufacturer-specific and lacked uniformity.

Q7: Do all cars have the same OBD2 PIDs?

No, while some PIDs are standardized, others are manufacturer-specific.

Q8: How often should I check my car’s OBD2 data?

Regularly monitoring key parameters can help identify potential issues early.

Q9: Can I use an OBD2 scanner to improve my car’s performance?

Yes, but proceed with caution and consult with a qualified tuner to avoid damaging your vehicle.

Q10: What should I do if my OBD2 scanner is not connecting to my car?

Check the connection, verify compatibility, and ensure that the scanner supports the correct protocol for your vehicle.

By understanding the OBD2 interface and its capabilities, you can take control of your Mercedes-Benz diagnostics and maintenance, ensuring optimal performance and longevity.

Ready to unlock the full potential of your Mercedes-Benz? Contact us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert guidance and the best diagnostic tools. Visit us at 789 Oak Avenue, Miami, FL 33101, United States or reach out via Whatsapp at +1 (641) 206-8880. Let us help you keep your Mercedes running at its best.