Using diagnostic tools to actuate the horn relay and check the switch status allows for precise troubleshooting and verification of the horn circuit’s functionality. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive solutions for Mercedes-Benz diagnostics, offering specialized tools and expertise to streamline the process. This article will explore how diagnostic tools can be used to effectively actuate the horn relay, check switch status, and ensure the overall integrity of your Mercedes-Benz’s horn system, including circuit testing and relay functionality.

Contents

- 1. Understanding the Horn Relay and Switch System

- What is a Horn Relay?

- What is a Horn Switch?

- Importance of the Horn System

- 2. Why Use Diagnostic Tools for Horn Relay Actuation?

- Precision and Accuracy

- Time Efficiency

- Comprehensive Testing

- Data Logging and Analysis

- 3. Types of Diagnostic Tools for Horn System Testing

- Multimeters

- Circuit Testers

- Scan Tools

- Oscilloscopes

- Specialized Relay Testers

- 4. Step-by-Step Guide to Actuating the Horn Relay with Diagnostic Tools

- Preparation

- Procedure

- Troubleshooting

- 5. Checking Horn Switch Status Using Diagnostic Tools

- Preparation

- Procedure

- Troubleshooting

- 6. Common Issues Identified by Diagnostic Tools in Horn Systems

- Relay Failure

- Switch Failure

- Wiring Problems

- Grounding Issues

- Horn Failure

- 7. Advanced Diagnostic Techniques for Complex Horn Problems

- Voltage Drop Testing

- Signal Tracing

- Component Isolation

- Data Logging and Analysis

- 8. Benefits of Regular Horn System Diagnostics

- Preventive Maintenance

- Safety Assurance

- Cost Savings

- Improved Reliability

- 9. Selecting the Right Diagnostic Tool for Your Mercedes-Benz

- Compatibility

- Features

- Ease of Use

- Cost

- 10. Expert Tips for Effective Horn System Diagnosis

- Consult the Wiring Diagram

- Check the Basics First

- Use a Systematic Approach

- Pay Attention to Detail

- Use Data Logging

- 11. Case Studies: Successful Horn System Repairs with Diagnostic Tools

- Case Study 1: Faulty Horn Relay

- Case Study 2: Corroded Horn Switch

- Case Study 3: Broken Wire

- 12. FAQs: Troubleshooting Horn Relay and Switch Issues

- Q1: What are the common symptoms of a faulty horn relay?

- Q2: How can I test a horn relay?

- Q3: What are the common symptoms of a faulty horn switch?

- Q4: How can I test a horn switch?

- Q5: What causes a horn relay to fail?

- Q6: What causes a horn switch to fail?

- Q7: Can I replace a horn relay myself?

- Q8: Can I replace a horn switch myself?

- Q9: How often should I have my horn system checked?

- Q10: What diagnostic tools does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offer for horn system testing?

Table of Contents

1. Understanding the Horn Relay and Switch System

2. Why Use Diagnostic Tools for Horn Relay Actuation?

3. Types of Diagnostic Tools for Horn System Testing

4. Step-by-Step Guide to Actuating the Horn Relay with Diagnostic Tools

5. Checking Horn Switch Status Using Diagnostic Tools

6. Common Issues Identified by Diagnostic Tools in Horn Systems

7. Advanced Diagnostic Techniques for Complex Horn Problems

8. Benefits of Regular Horn System Diagnostics

9. Selecting the Right Diagnostic Tool for Your Mercedes-Benz

10. Expert Tips for Effective Horn System Diagnosis

11. Case Studies: Successful Horn System Repairs with Diagnostic Tools

12. FAQs: Troubleshooting Horn Relay and Switch Issues

1. Understanding the Horn Relay and Switch System

The horn system in a Mercedes-Benz relies on a network of components working in harmony to deliver an audible signal. Central to this system are the horn relay and switch.

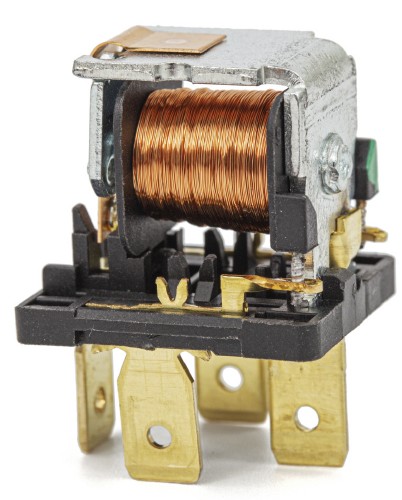

What is a Horn Relay?

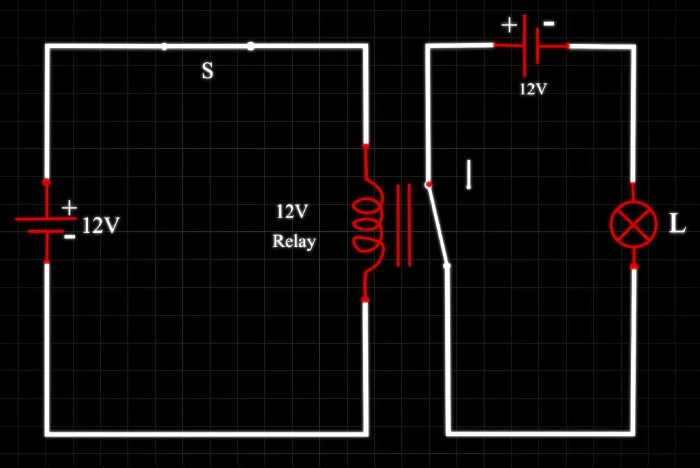

A horn relay is an electrical switch that allows a low-current circuit to control a high-current circuit. According to automotive electrical engineering principles, relays protect the horn switch from the high current needed to power the horn, ensuring the switch doesn’t burn out prematurely. The relay consists of a coil, an armature, and a set of contacts. When the horn switch is activated, it sends a small current to the relay coil, creating an electromagnetic field that pulls the armature, closing the contacts and allowing the high current to flow to the horn.

What is a Horn Switch?

The horn switch is typically located on the steering wheel and is responsible for initiating the horn signal. When pressed, the switch completes a circuit, sending a signal to the horn relay. The switch must be reliable to ensure the horn functions correctly when needed.

Importance of the Horn System

The horn is a critical safety device in any vehicle. It’s used to alert other drivers, pedestrians, and cyclists of your presence, potentially preventing accidents. A malfunctioning horn can compromise safety, making it essential to diagnose and repair any issues promptly.

2. Why Use Diagnostic Tools for Horn Relay Actuation?

Traditional methods of testing the horn system, such as manual inspection and basic circuit testing, can be time-consuming and may not accurately pinpoint the problem. Diagnostic tools offer several advantages:

Precision and Accuracy

Diagnostic tools provide precise measurements and real-time data, allowing technicians to accurately assess the functionality of the horn relay and switch. According to Bosch Automotive Handbook, modern diagnostic tools can read voltage, current, and resistance values with high accuracy, ensuring no subtle issues are overlooked.

Time Efficiency

Using diagnostic tools speeds up the diagnostic process by automating many of the testing procedures. Instead of manually checking each component, technicians can use diagnostic tools to quickly identify faults, saving time and labor costs.

Comprehensive Testing

Diagnostic tools can perform a wide range of tests, including actuation tests, circuit tests, and component tests, providing a comprehensive evaluation of the entire horn system. This holistic approach ensures that all potential issues are identified and addressed.

Data Logging and Analysis

Many diagnostic tools have data logging capabilities, allowing technicians to record and analyze data over time. This feature is particularly useful for diagnosing intermittent issues that may not be present during a static test.

3. Types of Diagnostic Tools for Horn System Testing

Several diagnostic tools are available for testing horn systems, each with its own set of features and capabilities. Choosing the right tool depends on the specific needs of the technician and the complexity of the vehicle’s electrical system.

Multimeters

Multimeters are versatile tools that can measure voltage, current, and resistance. They are essential for basic circuit testing and can be used to check the continuity of the horn switch and the voltage at the horn relay.

Circuit Testers

Circuit testers are simple tools that light up when they detect voltage. They are useful for quickly checking if a circuit is live and can help identify open circuits or shorts.

Scan Tools

Scan tools are more advanced diagnostic tools that can communicate with the vehicle’s computer system. They can read diagnostic trouble codes (DTCs), perform actuation tests, and provide real-time data. Scan tools are particularly useful for diagnosing complex issues in modern vehicles.

Oscilloscopes

Oscilloscopes are high-end diagnostic tools that display electrical signals as waveforms. They can be used to analyze the performance of the horn relay and switch in detail, identifying issues such as signal distortion or noise.

Specialized Relay Testers

Specialized relay testers are designed specifically for testing relays. They can quickly check the functionality of the relay by simulating the control signal and monitoring the output.

Automotive Relay

Automotive Relay

4. Step-by-Step Guide to Actuating the Horn Relay with Diagnostic Tools

Actuating the horn relay with diagnostic tools involves using the tool to send a signal to the relay, mimicking the action of the horn switch. This allows technicians to verify the relay’s functionality without pressing the horn switch.

Preparation

- Gather Your Tools: Ensure you have the necessary diagnostic tool, a multimeter, and the vehicle’s wiring diagram.

- Locate the Horn Relay: Consult the vehicle’s service manual to find the location of the horn relay. It is typically found in the fuse box under the hood or in the cabin.

- Safety Precautions: Disconnect the negative terminal of the battery to prevent electrical shorts or damage to the vehicle’s electrical system.

Procedure

- Connect the Diagnostic Tool: Connect the diagnostic tool to the vehicle’s diagnostic port (OBD-II port).

- Access the Relay Actuation Function: Navigate to the appropriate menu in the diagnostic tool to access the relay actuation function. This may be labeled as “Actuation Tests,” “Component Tests,” or similar.

- Select the Horn Relay: Choose the horn relay from the list of available components.

- Initiate Actuation: Follow the prompts on the diagnostic tool to initiate the actuation test. The tool will send a signal to the horn relay, causing it to activate.

- Verify Horn Activation: Listen for the horn to sound. If the horn sounds, the relay is functioning correctly. If the horn does not sound, proceed to the next step.

- Check Voltage at the Horn: Use a multimeter to check the voltage at the horn connector. If there is voltage, the issue may be with the horn itself. If there is no voltage, the problem is likely with the relay or the wiring between the relay and the horn.

Troubleshooting

- No Horn Sound: If the horn does not sound during the actuation test, check the relay itself. Use a multimeter to verify that the relay is receiving power and ground. If the relay is receiving power and ground, replace the relay with a new one and repeat the test.

- Intermittent Horn Sound: If the horn sounds intermittently, there may be a loose connection or a faulty relay. Check the wiring and connectors for corrosion or damage. Replace the relay if necessary.

5. Checking Horn Switch Status Using Diagnostic Tools

Checking the horn switch status involves using diagnostic tools to monitor the switch’s operation and identify any issues such as open circuits or shorts.

Preparation

- Gather Your Tools: Ensure you have the necessary diagnostic tool, a multimeter, and the vehicle’s wiring diagram.

- Locate the Horn Switch Connector: Consult the vehicle’s service manual to find the location of the horn switch connector. This is typically located behind the steering wheel.

- Safety Precautions: Disconnect the negative terminal of the battery to prevent electrical shorts or damage to the vehicle’s electrical system.

Procedure

- Connect the Diagnostic Tool: Connect the diagnostic tool to the vehicle’s diagnostic port (OBD-II port).

- Access the Switch Status Function: Navigate to the appropriate menu in the diagnostic tool to access the switch status function. This may be labeled as “Data Stream,” “Live Data,” or similar.

- Select the Horn Switch: Choose the horn switch from the list of available components.

- Monitor Switch Status: Press the horn switch and observe the status displayed on the diagnostic tool. The status should change from “Inactive” to “Active” when the switch is pressed.

- Verify Continuity: Use a multimeter to check the continuity of the horn switch. With the switch not pressed, there should be no continuity. When the switch is pressed, there should be continuity.

Troubleshooting

- Switch Not Activating: If the diagnostic tool does not register the switch as activating when pressed, check the switch itself. Use a multimeter to verify that the switch is receiving power and ground. If the switch is receiving power and ground, replace the switch with a new one and repeat the test.

- Intermittent Activation: If the switch activates intermittently, there may be a loose connection or a faulty switch. Check the wiring and connectors for corrosion or damage. Replace the switch if necessary.

6. Common Issues Identified by Diagnostic Tools in Horn Systems

Diagnostic tools can help identify a variety of issues in horn systems, ranging from simple wiring problems to more complex component failures.

Relay Failure

Relays can fail due to various reasons, including overheating, corrosion, and mechanical wear. Diagnostic tools can identify relay failures by performing actuation tests and monitoring the relay’s response.

Switch Failure

Horn switches can fail due to mechanical wear, corrosion, and electrical shorts. Diagnostic tools can identify switch failures by monitoring the switch’s status and checking for continuity.

Wiring Problems

Wiring problems, such as open circuits, shorts, and loose connections, are common in horn systems. Diagnostic tools can identify wiring problems by performing circuit tests and checking for voltage drops.

Grounding Issues

Grounding issues can cause the horn to malfunction or not work at all. Diagnostic tools can identify grounding issues by checking the resistance between the ground point and the vehicle’s chassis.

Horn Failure

The horn itself can fail due to mechanical damage, corrosion, and electrical shorts. Diagnostic tools can identify horn failures by checking the voltage at the horn connector and listening for the horn to sound during actuation tests.

7. Advanced Diagnostic Techniques for Complex Horn Problems

For complex horn problems that cannot be easily diagnosed with basic tools, advanced diagnostic techniques may be necessary.

Voltage Drop Testing

Voltage drop testing involves measuring the voltage drop across a circuit to identify areas of high resistance. This technique is particularly useful for diagnosing wiring problems and grounding issues.

Signal Tracing

Signal tracing involves following the electrical signal through the circuit to identify the point where it is lost or distorted. This technique requires an oscilloscope and a good understanding of the vehicle’s electrical system.

Component Isolation

Component isolation involves disconnecting components one at a time to isolate the source of the problem. This technique is useful for diagnosing issues caused by shorted or faulty components.

Data Logging and Analysis

Data logging and analysis involve recording data over time and analyzing it to identify patterns and anomalies. This technique is particularly useful for diagnosing intermittent issues.

Automotive Relay Closed

Automotive Relay Closed

8. Benefits of Regular Horn System Diagnostics

Regular horn system diagnostics can help prevent unexpected failures and ensure the horn is always ready when needed.

Preventive Maintenance

Regular diagnostics can identify potential issues before they become major problems, allowing technicians to perform preventive maintenance and avoid costly repairs.

Safety Assurance

A properly functioning horn is essential for safety. Regular diagnostics ensure that the horn is always ready to alert other drivers and pedestrians, reducing the risk of accidents.

Cost Savings

By identifying and addressing issues early, regular diagnostics can help prevent major repairs and save money in the long run.

Improved Reliability

Regular diagnostics can help improve the reliability of the horn system by ensuring that all components are functioning correctly.

9. Selecting the Right Diagnostic Tool for Your Mercedes-Benz

Choosing the right diagnostic tool for your Mercedes-Benz depends on your needs and budget. Consider the following factors:

Compatibility

Ensure that the diagnostic tool is compatible with your Mercedes-Benz model and year. Some tools are designed specifically for certain makes and models.

Features

Consider the features that are important to you. Do you need a tool that can perform actuation tests, read DTCs, or provide real-time data?

Ease of Use

Choose a tool that is easy to use and has a clear and intuitive interface. A complex tool can be frustrating to use and may not provide accurate results.

Cost

Diagnostic tools range in price from a few hundred dollars to several thousand dollars. Choose a tool that fits your budget and provides the features you need.

At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer a range of diagnostic tools specifically designed for Mercedes-Benz vehicles. Our tools provide comprehensive diagnostics, actuation tests, and real-time data, ensuring you can accurately diagnose and repair any issues with your horn system.

10. Expert Tips for Effective Horn System Diagnosis

Here are some expert tips to help you effectively diagnose horn system issues:

Consult the Wiring Diagram

Always consult the vehicle’s wiring diagram before starting any diagnostic work. The wiring diagram provides valuable information about the circuit layout and component locations.

Check the Basics First

Before using diagnostic tools, check the basics, such as the fuse and the horn relay. A blown fuse or a faulty relay can often be the cause of the problem.

Use a Systematic Approach

Use a systematic approach to diagnose horn system issues. Start by checking the horn itself, then move on to the relay, the switch, and the wiring.

Pay Attention to Detail

Pay attention to detail when inspecting the wiring and connectors. Look for corrosion, damage, and loose connections.

Use Data Logging

Use data logging to capture intermittent issues. This can help you identify the root cause of the problem more quickly.

11. Case Studies: Successful Horn System Repairs with Diagnostic Tools

Here are a few case studies that demonstrate the effectiveness of using diagnostic tools for horn system repairs:

Case Study 1: Faulty Horn Relay

A customer complained that their horn was not working. The technician used a diagnostic tool to perform an actuation test on the horn relay. The horn did not sound, indicating a faulty relay. The technician replaced the relay, and the horn began working again.

Case Study 2: Corroded Horn Switch

A customer complained that their horn was working intermittently. The technician used a diagnostic tool to monitor the horn switch status. The status was intermittent, indicating a faulty switch. The technician inspected the switch and found that it was corroded. The technician cleaned the switch, and the horn began working reliably.

Case Study 3: Broken Wire

A customer complained that their horn was not working. The technician used a diagnostic tool to perform a circuit test on the horn circuit. The circuit was open, indicating a broken wire. The technician traced the wire and found a break. The technician repaired the wire, and the horn began working again.

These case studies illustrate how diagnostic tools can help technicians quickly and accurately diagnose horn system issues, leading to successful repairs.

12. FAQs: Troubleshooting Horn Relay and Switch Issues

Here are some frequently asked questions about troubleshooting horn relay and switch issues:

Q1: What are the common symptoms of a faulty horn relay?

A1: Common symptoms include the horn not working, working intermittently, or staying on continuously.

Q2: How can I test a horn relay?

A2: You can test a horn relay using a multimeter or a specialized relay tester. Check for continuity between the relay’s terminals and perform an actuation test.

Q3: What are the common symptoms of a faulty horn switch?

A3: Common symptoms include the horn not working, working intermittently, or requiring excessive force to activate.

Q4: How can I test a horn switch?

A4: You can test a horn switch using a multimeter. Check for continuity between the switch’s terminals when the switch is pressed.

Q5: What causes a horn relay to fail?

A5: Common causes include overheating, corrosion, mechanical wear, and electrical shorts.

Q6: What causes a horn switch to fail?

A6: Common causes include mechanical wear, corrosion, and electrical shorts.

Q7: Can I replace a horn relay myself?

A7: Yes, if you have basic mechanical skills and a multimeter. However, if you are not comfortable working on your vehicle, it is best to take it to a qualified technician.

Q8: Can I replace a horn switch myself?

A8: Replacing a horn switch can be more complex, as it typically involves removing the steering wheel. If you are not comfortable with this procedure, it is best to take your vehicle to a qualified technician.

Q9: How often should I have my horn system checked?

A9: It is recommended to have your horn system checked at least once a year as part of your regular vehicle maintenance.

Q10: What diagnostic tools does MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offer for horn system testing?

A10: At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer a range of diagnostic tools specifically designed for Mercedes-Benz vehicles. Our tools provide comprehensive diagnostics, actuation tests, and real-time data, ensuring you can accurately diagnose and repair any issues with your horn system.

By understanding the horn relay and switch system, using diagnostic tools effectively, and following expert tips, you can ensure that your Mercedes-Benz’s horn is always ready when needed, promoting safety and preventing accidents.

Are you experiencing issues with your Mercedes-Benz’s horn system? Don’t compromise on safety. Contact us at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for expert assistance. Our team of certified technicians can provide comprehensive diagnostics, repair services, and maintenance tips to keep your horn system in top condition. Reach out to us today at 789 Oak Avenue, Miami, FL 33101, United States, or call us on Whatsapp at +1 (641) 206-8880. Visit our website at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for more information.