Diagnostic tools can be used to check the seatbelt buckle switch by reading Diagnostic Trouble Codes (DTCs) stored by the vehicle’s computer. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers in-depth diagnostics and precise solutions that will help you maintain and repair your car effectively. By understanding the functionality and using diagnostic tools effectively, you can identify and address seatbelt buckle switch issues, ensuring your Mercedes-Benz operates safely and reliably. With comprehensive diagnostic tools and expert guidance, you can successfully test safety restraint systems and solve safety system problems.

1. Understanding the Seatbelt Buckle Switch

The seatbelt buckle switch is a critical component of your Mercedes-Benz safety system. It detects whether the seatbelt is buckled or unbuckled, sending this information to the vehicle’s computer. This data is then used to activate the seatbelt warning light and, in some cases, influence the deployment of airbags during a collision. A faulty seatbelt buckle switch can lead to several issues, including:

- Seatbelt warning light staying on even when the seatbelt is buckled.

- Seatbelt warning light not illuminating when the seatbelt is unbuckled.

- Potential impact on airbag deployment during an accident.

1.1 The Role of Hall Effect Sensors

Modern Mercedes-Benz vehicles often use Hall Effect sensors within the seatbelt buckle. These sensors are more reliable and durable than traditional mechanical switches.

- Hall Effect Sensor Operation: A Hall Effect sensor consists of a fixed-position Integrated Circuit (IC) chip and a small permanent magnet. When the seatbelt is latched, a slide exposes the IC chip to the magnetic field, inducing a current. This current signals that the seatbelt is buckled. When the seatbelt is unbuckled, the slide shields the IC, reducing the current and signaling that the seatbelt is unbuckled.

- Advantages of Hall Effect Sensors: These sensors are less prone to wear and tear compared to mechanical switches, offering longer-lasting performance and more reliable readings.

1.2 Components of the Seatbelt Buckle Switch System

The seatbelt buckle switch system includes several interconnected components:

- Seatbelt Buckle: Contains the Hall Effect sensor (or mechanical switch) that detects the seatbelt’s state.

- Wiring Harness: Connects the seatbelt buckle switch to the vehicle’s electrical system.

- Occupant Restraint Controller (ORC) / Occupant Classification Module (OCM): Receives signals from the seatbelt switch and communicates this information to other vehicle systems.

- Instrument Panel Cluster (IPC): Displays the seatbelt warning light based on signals from the ORC/OCM.

2. Why Use Diagnostic Tools for Seatbelt Buckle Switch Issues?

Diagnostic tools offer a precise and efficient way to diagnose seatbelt buckle switch problems. While visual inspections can sometimes reveal obvious damage, they often fall short in identifying underlying electrical or sensor malfunctions.

2.1 Limitations of Conventional Diagnostic Methods

Conventional diagnostic methods, such as using a multimeter to check continuity, may not provide conclusive results. These methods may fail to detect intermittent faults or communication issues between the seatbelt switch and other vehicle modules.

2.2 Benefits of Using Diagnostic Scan Tools

Diagnostic scan tools offer several advantages:

- Reading Diagnostic Trouble Codes (DTCs): Scan tools can retrieve DTCs stored in the ORC or OCM, providing specific information about the nature of the fault.

- Live Data Monitoring: Some advanced scan tools can monitor live data from the seatbelt switch, allowing you to observe its behavior in real-time and identify any anomalies.

- Component Testing: Certain scan tools offer component testing functions that can activate the seatbelt switch and verify its operation.

- System Communication Analysis: Scan tools can analyze communication between different vehicle modules, helping to identify issues in the CAN data bus that may affect seatbelt switch operation.

2.3 Diagnostic Tools Recommended by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN recommends several diagnostic tools that are effective for diagnosing seatbelt buckle switch issues in Mercedes-Benz vehicles:

- Mercedes-Benz Star Diagnosis System (XENTRY/DAS): The official diagnostic tool used by Mercedes-Benz dealerships, offering comprehensive diagnostic and programming capabilities.

- iCarsoft MB II: A popular aftermarket scan tool that provides extensive coverage for Mercedes-Benz vehicles, including seatbelt system diagnostics.

- Autel MaxiCOM MK808: A versatile scan tool that offers a wide range of diagnostic functions, including DTC reading, live data monitoring, and component testing.

- Launch X431 V+: A professional-grade scan tool with advanced diagnostic features and extensive vehicle coverage.

3. Step-by-Step Guide: Checking the Seatbelt Buckle Switch with Diagnostic Tools

Follow these steps to effectively check the seatbelt buckle switch using a diagnostic tool:

3.1 Preparation

- Gather Necessary Tools and Equipment:

- Diagnostic scan tool (e.g., Mercedes-Benz Star Diagnosis, iCarsoft MB II, Autel MaxiCOM MK808, Launch X431 V+).

- OBD-II cable to connect the scan tool to the vehicle.

- Vehicle’s repair manual or wiring diagram (optional, but helpful).

- Ensure Vehicle Readiness:

- Park the vehicle on a level surface.

- Engage the parking brake.

- Turn off the engine.

- Connect the Diagnostic Scan Tool:

- Locate the OBD-II port in your Mercedes-Benz (typically under the dashboard on the driver’s side).

- Plug the OBD-II cable into the port.

- Turn on the diagnostic scan tool.

3.2 Reading Diagnostic Trouble Codes (DTCs)

- Power On and Select Vehicle:

- Turn the vehicle’s ignition to the “ON” position (do not start the engine).

- Follow the scan tool’s prompts to select the correct vehicle make, model, and year.

- Navigate to the Appropriate Module:

- In the scan tool’s menu, navigate to the “Control Units” or “Modules” section.

- Select the “Occupant Restraint Controller (ORC)” or “Occupant Classification Module (OCM)” module.

- Read DTCs:

- Choose the “Read Codes” or “Diagnostic Trouble Codes” option.

- The scan tool will display any stored DTCs related to the seatbelt system.

- Record and Interpret DTCs:

- Write down each DTC and its description.

- Consult the vehicle’s repair manual or online resources to understand the meaning of each code.

- Common DTCs related to the seatbelt buckle switch include:

- B1476 – Driver’s Seat Belt Buckle Switch Circuit Fault

- B1477 – Passenger’s Seat Belt Buckle Switch Circuit Fault

- B102C – Seat Belt Buckle Switch Malfunction

3.3 Live Data Monitoring

- Access Live Data:

- In the scan tool’s menu, select the “Live Data” or “Data Stream” option.

- Select Relevant Parameters:

- Choose parameters related to the seatbelt buckle switch, such as:

- Driver’s Seat Belt Buckle Switch Status

- Passenger’s Seat Belt Buckle Switch Status

- Seat Belt Buckle Switch Voltage

- Choose parameters related to the seatbelt buckle switch, such as:

- Monitor Switch Operation:

- Buckle and unbuckle the seatbelt while observing the live data.

- Verify that the switch status changes accordingly (e.g., from “Unbuckled” to “Buckled”).

- Check for any erratic or inconsistent readings.

3.4 Component Testing (if available)

- Enter Component Testing Mode:

- In the scan tool’s menu, look for a “Component Tests” or “Actuation Tests” option.

- Select Seatbelt Buckle Switch Test:

- Choose the test specifically designed for the seatbelt buckle switch.

- Follow On-Screen Instructions:

- The scan tool will provide instructions on how to perform the test, such as activating the switch and monitoring its response.

- Observe the results and compare them to the expected values.

3.5 Interpreting Results and Taking Action

- DTCs Present: If DTCs are present, research the specific codes to understand the nature of the fault. This may involve checking the wiring, replacing the seatbelt buckle switch, or diagnosing other related components.

- Inconsistent Live Data: If the live data shows erratic or inconsistent readings, the seatbelt buckle switch may be faulty and require replacement.

- Failed Component Test: If the component test fails, it confirms that the seatbelt buckle switch is not functioning correctly and needs to be replaced.

- No Issues Found: If no DTCs are present and the live data and component tests appear normal, the problem may lie elsewhere in the seatbelt system, such as the wiring or the ORC/OCM.

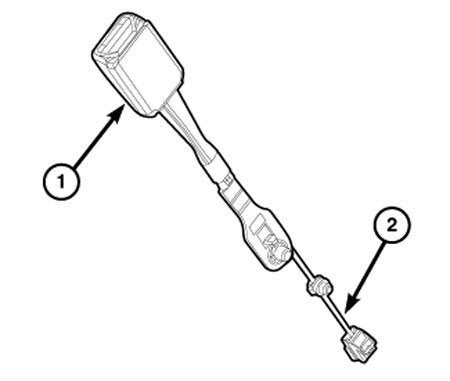

Seat Belt Buckle Switch

Seat Belt Buckle Switch

4. Common Issues and Troubleshooting Tips

Several common issues can arise with seatbelt buckle switches, and understanding these problems can aid in effective troubleshooting.

4.1 Common DTCs and Their Meanings

- B1476/B1477 (Driver/Passenger Seat Belt Buckle Switch Circuit Fault): Indicates an open or short circuit in the seatbelt buckle switch wiring.

- B102C (Seat Belt Buckle Switch Malfunction): Suggests a problem with the switch itself, such as a faulty sensor or internal damage.

4.2 Wiring Problems

- Visual Inspection: Check the wiring harness connected to the seatbelt buckle switch for any signs of damage, such as frayed wires, corrosion, or loose connectors.

- Continuity Testing: Use a multimeter to test the continuity of the wiring between the seatbelt buckle switch and the ORC/OCM. Refer to the vehicle’s wiring diagram for the correct pin assignments.

- Voltage Testing: With the ignition on, use a multimeter to check for proper voltage at the seatbelt buckle switch connector.

4.3 Switch Malfunction

- Resistance Testing: Use a multimeter to measure the resistance of the seatbelt buckle switch in both the buckled and unbuckled states. Compare the readings to the specifications in the vehicle’s repair manual.

- Physical Damage: Inspect the seatbelt buckle switch for any signs of physical damage, such as cracks, broken parts, or corrosion.

4.4 Addressing Specific Scenarios

- Seatbelt Warning Light Stays On: This often indicates that the seatbelt buckle switch is stuck in the “unbuckled” position. Check for debris or obstructions in the buckle, and try cleaning it with compressed air or electrical contact cleaner. If the problem persists, the switch may need to be replaced.

- Seatbelt Warning Light Does Not Illuminate: This may indicate that the seatbelt buckle switch is stuck in the “buckled” position or that there is a problem with the wiring or the ORC/OCM. Check the wiring and test the switch using a multimeter.

- Intermittent Issues: Intermittent problems can be challenging to diagnose. Try monitoring the live data from the seatbelt buckle switch while wiggling the wiring harness to see if the readings change. This can help identify loose connections or damaged wires.

5. When to Replace the Seatbelt Buckle Switch

In some cases, troubleshooting may reveal that the seatbelt buckle switch needs to be replaced. Here are some signs that indicate a replacement is necessary:

- Physical Damage: If the seatbelt buckle switch is physically damaged, such as cracked or broken, it should be replaced.

- Failed Resistance Test: If the resistance readings are outside the specified range, the switch is likely faulty.

- Inconsistent Live Data: If the live data readings are erratic or inconsistent, the switch may be failing.

- Failed Component Test: If the component test fails, the switch is not functioning correctly.

5.1 Choosing the Right Replacement Part

When replacing the seatbelt buckle switch, it is important to choose the correct part for your vehicle.

- OEM vs. Aftermarket: OEM (Original Equipment Manufacturer) parts are made by the same manufacturer that supplied the original part. Aftermarket parts are made by other companies and may be less expensive. While aftermarket parts can be a viable option, OEM parts are generally recommended for critical safety components like the seatbelt buckle switch.

- Part Number Verification: Verify the part number in your vehicle’s repair manual or by contacting a Mercedes-Benz dealership. This ensures that you are purchasing the correct part for your vehicle.

5.2 Replacement Procedure

Replacing the seatbelt buckle switch typically involves the following steps:

- Disconnect the Battery: Disconnect the negative battery cable to prevent electrical shorts.

- Remove the Seat: In most cases, it is necessary to remove the seat to access the seatbelt buckle switch.

- Disconnect the Wiring Harness: Disconnect the wiring harness from the seatbelt buckle switch.

- Remove the Old Switch: Remove the screw or fastener that secures the seatbelt buckle switch to the seat frame.

- Install the New Switch: Install the new seatbelt buckle switch and secure it with the screw or fastener.

- Reconnect the Wiring Harness: Reconnect the wiring harness to the seatbelt buckle switch.

- Reinstall the Seat: Reinstall the seat and secure it with the bolts.

- Reconnect the Battery: Reconnect the negative battery cable.

- Test the System: Use a diagnostic scan tool to clear any DTCs and verify that the seatbelt buckle switch is functioning correctly.

6. Advanced Diagnostic Techniques

For complex seatbelt system issues, advanced diagnostic techniques may be necessary.

6.1 Using Oscilloscopes

An oscilloscope can be used to analyze the signal from the seatbelt buckle switch in more detail. This can help identify subtle issues that may not be apparent with a multimeter or scan tool.

- Signal Analysis: Connect the oscilloscope to the seatbelt buckle switch wiring and observe the signal while bucking and unbuckling the seatbelt. Look for any abnormalities in the signal, such as noise, distortion, or dropouts.

- Troubleshooting: Use the oscilloscope to trace the signal through the wiring harness and identify any points where the signal is being interrupted or degraded.

6.2 Checking the CAN Data Bus

The seatbelt system relies on the Controller Area Network (CAN) data bus to communicate with other vehicle modules. Issues in the CAN data bus can affect seatbelt system operation.

- CAN Bus Testing: Use a diagnostic scan tool with CAN bus testing capabilities to check for communication errors or faults in the CAN data bus.

- Wiring Inspection: Inspect the CAN bus wiring for any signs of damage, such as frayed wires, corrosion, or loose connectors.

6.3 Consulting Technical Service Bulletins (TSBs)

Technical Service Bulletins (TSBs) are issued by Mercedes-Benz to provide information about common problems and repair procedures. Consulting TSBs can help identify known issues with the seatbelt system and provide guidance on how to resolve them.

7. Preventive Maintenance for Seatbelt Systems

Regular maintenance can help prevent seatbelt system problems and ensure that the system is functioning correctly.

7.1 Visual Inspections

- Monthly Checks: Perform a visual inspection of the seatbelts, buckles, and retractors on a monthly basis. Look for any signs of damage, such as frayed belts, cracked buckles, or sticky retractors.

- Cleaning: Clean the seatbelts and buckles with a mild detergent and water to remove any dirt or debris.

7.2 Functional Tests

- Regular Checks: Regularly test the seatbelts to ensure that they are retracting smoothly and locking properly.

- Buckle Test: Buckle and unbuckle the seatbelts to verify that the buckles are latching and releasing correctly.

7.3 Professional Inspections

- Annual Check-Ups: Have the seatbelt system inspected by a qualified technician during your vehicle’s annual check-up.

- Component Check: The technician can check the seatbelt buckles, retractors, and wiring for any signs of wear or damage.

8. Benefits of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides valuable resources and expertise for diagnosing and repairing Mercedes-Benz vehicles.

8.1 Comprehensive Diagnostic Information

- Extensive Database: Access a comprehensive database of DTCs, repair procedures, and technical information for Mercedes-Benz vehicles.

- Expert Guidance: Receive expert guidance from experienced Mercedes-Benz technicians.

8.2 Access to Advanced Diagnostic Tools

- Tool Recommendations: Get recommendations for the best diagnostic tools for your needs and budget.

- Tool Training: Receive training on how to use diagnostic tools effectively.

8.3 Cost Savings

- DIY Repairs: Save money by performing your own diagnostic and repair work.

- Informed Decisions: Make informed decisions about when to repair or replace components.

8.4 Ensuring Safety

- Proper Functionality: Ensure that your Mercedes-Benz safety systems are functioning correctly.

- Peace of Mind: Have peace of mind knowing that you are driving a safe and reliable vehicle.

9. How to Access MERCEDES-DIAGNOSTIC-TOOL.EDU.VN Resources

Accessing MERCEDES-DIAGNOSTIC-TOOL.EDU.VN resources is simple:

- Visit the Website: Go to MERCEDES-DIAGNOSTIC-TOOL.EDU.VN in your web browser.

- Explore the Resources: Navigate through the website to find diagnostic information, repair procedures, and tool recommendations.

- Contact Us: If you need assistance or have questions, contact us via WhatsApp at +1 (641) 206-8880 or visit our location at 789 Oak Avenue, Miami, FL 33101, United States.

10. Case Studies and Examples

To illustrate the effectiveness of using diagnostic tools for seatbelt buckle switch issues, consider these case studies:

10.1 Case Study 1: Intermittent Seatbelt Warning Light

- Problem: A Mercedes-Benz owner experienced an intermittent seatbelt warning light that would come on and off randomly.

- Diagnosis: Using a diagnostic scan tool, the technician found a stored DTC related to the driver’s seatbelt buckle switch circuit. Live data monitoring revealed that the switch status was fluctuating erratically.

- Solution: The technician replaced the driver’s seatbelt buckle switch, and the problem was resolved.

10.2 Case Study 2: Airbag Deployment Issues

- Problem: A Mercedes-Benz owner was concerned about potential airbag deployment issues after noticing that the seatbelt warning light was not functioning correctly.

- Diagnosis: Using a diagnostic scan tool, the technician found a DTC related to the passenger’s seatbelt buckle switch. Component testing confirmed that the switch was not functioning correctly.

- Solution: The technician replaced the passenger’s seatbelt buckle switch, ensuring that the airbag system would function properly in the event of a collision.

11. The Future of Seatbelt Diagnostics

The field of automotive diagnostics is constantly evolving, and seatbelt diagnostics are no exception.

11.1 Advancements in Diagnostic Tools

- More Sophisticated Tools: Future diagnostic tools will offer even more sophisticated diagnostic capabilities, such as advanced signal analysis and predictive diagnostics.

- Wireless Connectivity: Wireless connectivity will allow technicians to diagnose seatbelt system issues remotely.

11.2 Integration with Vehicle Systems

- Seamless Integration: Seatbelt diagnostics will become more seamlessly integrated with other vehicle systems, allowing for a more holistic approach to vehicle maintenance.

- Predictive Maintenance: Predictive maintenance technologies will use data from the seatbelt system to anticipate potential problems and schedule maintenance proactively.

11.3 The Role of MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN will continue to play a leading role in providing cutting-edge diagnostic information and resources for Mercedes-Benz vehicles. By staying abreast of the latest advancements in diagnostic technology, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN will empower Mercedes-Benz owners and technicians to keep their vehicles running safely and reliably.

12. FAQ: Checking the Seatbelt Buckle Switch

12.1 What diagnostic tool do I need to check the seatbelt buckle switch on my Mercedes-Benz?

You can use the Mercedes-Benz Star Diagnosis System (XENTRY/DAS), iCarsoft MB II, Autel MaxiCOM MK808, or Launch X431 V+. These tools can read DTCs, monitor live data, and perform component testing.

12.2 How often should I check the seatbelt buckle switch?

It’s recommended to perform a visual inspection monthly and a functional test regularly. Have a professional inspection during your vehicle’s annual check-up.

12.3 What are the common symptoms of a faulty seatbelt buckle switch?

Common symptoms include the seatbelt warning light staying on, not illuminating, or intermittent issues with the airbag system.

12.4 Can I replace the seatbelt buckle switch myself?

Yes, if you have mechanical skills, you can replace it yourself. Always disconnect the battery and follow the repair manual. If unsure, seek professional help.

12.5 What does a B1476 DTC code mean for the seatbelt system?

A B1476 DTC code indicates a fault in the driver’s seat belt buckle switch circuit. Check the wiring and the switch itself.

12.6 How do Hall Effect sensors work in seatbelt buckles?

Hall Effect sensors use a magnetic field to detect if the seatbelt is buckled. When buckled, the magnetic field induces a current, signaling the system.

12.7 What should I look for when inspecting the wiring of the seatbelt buckle switch?

Check for frayed wires, corrosion, or loose connectors. Use a multimeter to test the continuity of the wiring.

12.8 Are OEM seatbelt buckle switches better than aftermarket ones?

OEM parts are generally recommended for critical safety components like seatbelt buckle switches due to their reliability and quality.

12.9 How do I test the seatbelt buckle switch with a multimeter?

Measure the resistance of the switch in both buckled and unbuckled states. Compare the readings to the specifications in the vehicle’s repair manual.

12.10 Where can I find the vehicle’s wiring diagram for the seatbelt system?

You can find it in your vehicle’s repair manual or through online resources specific to your Mercedes-Benz model.

13. Call to Action

Don’t compromise on safety. Ensure your Mercedes-Benz seatbelt system functions flawlessly. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide in-depth diagnostics and precise solutions to maintain and repair your car effectively. Contact us today for expert guidance and access to advanced diagnostic tools.

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Whether you need help diagnosing a seatbelt warning light issue, understanding diagnostic trouble codes, or guidance on preventive maintenance, MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is here to assist. Reach out now and ensure your vehicle’s safety systems are in optimal condition!