How Is The Steering Angle Sensor Calibrated Using Mercedes Diagnostics? Calibrating the steering angle sensor (SAS) on your Mercedes-Benz is vital for ensuring the proper function of safety systems like ESP and adaptive cruise control, and this can be achieved effectively with Mercedes diagnostic tools. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer detailed insights and guidance on using these tools for accurate SAS calibration. Proper calibration guarantees optimal performance, enhanced safety, and a seamless driving experience. Explore sensor calibration and diagnostic tools, ensuring the precision of electronic stability program.

Contents

- 1. Understanding the Steering Angle Sensor (SAS)

- Function of the SAS

- How the SAS Works

- 2. Why Steering Angle Sensor Calibration is Important

- Ensuring System Accuracy

- When Calibration is Needed

- Impact on Vehicle Safety

- 3. Common Symptoms of a Miscalibrated Steering Angle Sensor

- Warning Lights on the Dashboard

- Malfunctioning Safety Systems

- Unusual Driving Behavior

- Expert Insight

- 4. Tools Required for Steering Angle Sensor Calibration

- Diagnostic Scanners

- Alignment Equipment

- Other Necessary Tools

- Software and Updates

- 5. Step-by-Step Guide: Calibrating SAS Using Mercedes Diagnostics

- Step 1: Preparation

- Step 2: Connect Diagnostic Scanner

- Step 3: Access SAS Calibration Function

- Step 4: Perform Calibration

- Step 5: Verify Calibration

- Expert Tips

- 6. Mercedes-Benz Specific Calibration Procedures

- Model-Specific Variations

- Examples of Model-Specific Procedures

- Importance of Service Information

- Accessing Service Information

- Expert Advice

- 7. Advanced Diagnostic Procedures for SAS Issues

- Analyzing Live Data

- Sensor Testing

- Component Inspection

- Expert Insight

- 8. Potential Problems During Calibration and How to Solve Them

- Communication Errors

- Solutions

- Incorrect Readings

- Solutions

- Calibration Failures

- Solutions

- Expert Advice

- 9. Best Practices for Maintaining Steering Angle Sensor Accuracy

- Regular Inspections

- Proper Alignment

- Timely Recalibration

- Expert Insight

- 10. Benefits of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for SAS Calibration

- Expert Guidance

- Detailed Tutorials

- Comprehensive Support

- Expert Insight

- 11. FAQ: Steering Angle Sensor Calibration on Mercedes-Benz Vehicles

- Q1: What is a steering angle sensor (SAS)?

- Q2: Why is SAS calibration necessary?

- Q3: When should I calibrate the SAS?

- Q4: What tools are required for SAS calibration?

- Q5: How do I access the SAS calibration function on the diagnostic scanner?

- Q6: What are the common symptoms of a miscalibrated SAS?

- Q7: Can I calibrate the SAS myself?

- Q8: What are the potential problems during calibration?

- Q9: How can I maintain SAS accuracy?

- Q10: Where can I find expert guidance on SAS calibration?

- 12. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Expert Assistance

- Contact Information

Table of Contents

- Understanding the Steering Angle Sensor (SAS)

- Why Steering Angle Sensor Calibration is Important

- Common Symptoms of a Miscalibrated Steering Angle Sensor

- Tools Required for Steering Angle Sensor Calibration

- Step-by-Step Guide: Calibrating SAS Using Mercedes Diagnostics

- Mercedes-Benz Specific Calibration Procedures

- Advanced Diagnostic Procedures for SAS Issues

- Potential Problems During Calibration and How to Solve Them

- Best Practices for Maintaining Steering Angle Sensor Accuracy

- Benefits of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for SAS Calibration

- FAQ: Steering Angle Sensor Calibration on Mercedes-Benz Vehicles

- Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Expert Assistance

1. Understanding the Steering Angle Sensor (SAS)

What does the steering angle sensor (SAS) do in a Mercedes-Benz? The steering angle sensor (SAS) is a crucial component in modern vehicles, particularly in Mercedes-Benz models. It accurately measures the position of the steering wheel, providing essential data to various vehicle systems, enhancing vehicle dynamics control.

Function of the SAS

The SAS is typically located around the steering column and works by tracking the steering wheel’s rotation. This information is relayed to the vehicle’s computer systems, enabling functions such as:

- Electronic Stability Program (ESP): ESP uses the SAS data to determine if the vehicle is turning as intended by the driver. If a discrepancy is detected, ESP can intervene by applying brakes to individual wheels to help prevent skidding or loss of control.

- Adaptive Cruise Control (ACC): ACC systems use SAS data to maintain a safe distance from other vehicles while cruising. The sensor ensures the vehicle follows the curvature of the road, providing a more seamless and safer driving experience.

- Lane Keeping Assist (LKA): LKA systems rely on the SAS to keep the vehicle centered in its lane. The data helps the system make minor steering adjustments to prevent unintentional lane departures.

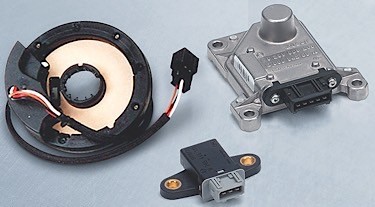

How the SAS Works

The steering angle sensor (SAS) typically uses optical or magnetic sensors to measure the steering wheel’s angle. Optical sensors shine a light beam through a coded disc attached to the steering shaft, while magnetic sensors detect changes in a magnetic field as the steering wheel turns. Both types provide precise angular measurements, allowing the car’s computer to react accurately to driving maneuvers.

The SAS works in conjunction with other sensors, such as yaw sensors and accelerometers, to provide a comprehensive picture of the vehicle’s dynamics. According to a study by the University of California, Berkeley, the integration of these sensors enhances the effectiveness of vehicle stability control systems. The data fusion from multiple sensors allows for more accurate and timely interventions, improving overall vehicle safety.

Steering angle sensor works with the yaw and accelerometer to determine what the vehicle is doing and what the driver wants the vehicle to do

Steering angle sensor works with the yaw and accelerometer to determine what the vehicle is doing and what the driver wants the vehicle to do

2. Why Steering Angle Sensor Calibration is Important

Why is steering angle sensor calibration so important for Mercedes-Benz vehicles? Steering angle sensor calibration is critical to ensuring the accuracy and reliability of numerous safety and driving assistance systems in your Mercedes-Benz, contributing to enhanced driver safety and vehicle performance.

Ensuring System Accuracy

The steering angle sensor (SAS) must be accurately calibrated to provide correct data to the vehicle’s control systems. When the SAS is miscalibrated, it sends incorrect information, which can lead to:

- Malfunctioning ESP: If the SAS isn’t calibrated correctly, the ESP system might engage unnecessarily or fail to engage when needed, increasing the risk of accidents.

- ACC Issues: A miscalibrated SAS can cause the adaptive cruise control to misjudge distances and road curvature, resulting in erratic speed adjustments and potential collisions.

- LKA Problems: Incorrect SAS data can lead to the lane keeping assist system making improper steering corrections, causing driver discomfort and potentially dangerous situations.

When Calibration is Needed

Steering angle sensor calibration is typically required in several scenarios:

- After Wheel Alignment: Adjusting the wheel alignment can affect the steering angle sensor’s accuracy, necessitating recalibration to ensure all systems work in harmony.

- After Suspension Work: Any repairs or modifications to the suspension system can alter the vehicle’s geometry, impacting the SAS and requiring a reset.

- After Replacing SAS: When the steering angle sensor is replaced, it must be calibrated to match the vehicle’s specific settings.

- Battery Replacement: In some Mercedes-Benz models, disconnecting and reconnecting the battery can cause the SAS to lose its calibration.

- ESP or ABS Repairs: Work on the electronic stability program (ESP) or anti-lock braking system (ABS) can sometimes necessitate SAS calibration.

Impact on Vehicle Safety

The safety systems in modern vehicles are interconnected, with the SAS serving as a vital data provider. Proper calibration ensures that these systems function as intended, enhancing vehicle safety. A study by the National Highway Traffic Safety Administration (NHTSA) found that properly calibrated ESP systems significantly reduce the risk of single-vehicle crashes, particularly on slippery surfaces.

3. Common Symptoms of a Miscalibrated Steering Angle Sensor

What are the signs of a miscalibrated steering angle sensor in a Mercedes-Benz? A miscalibrated steering angle sensor can manifest in several noticeable symptoms, including warning lights, system malfunctions, and unusual driving behavior, all of which can be accurately diagnosed and resolved with the diagnostic tools and services available at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

Warning Lights on the Dashboard

One of the most common indicators of a miscalibrated steering angle sensor is the illumination of warning lights on the dashboard. These lights are designed to alert the driver to potential issues with the vehicle’s safety systems. Specific warning lights related to SAS issues include:

- ESP (Electronic Stability Program) Warning Light: This light indicates that the ESP system is not functioning correctly, which can be a direct result of a miscalibrated SAS.

- ABS (Anti-lock Braking System) Warning Light: In some cases, a faulty SAS can also trigger the ABS warning light, as these systems often work together.

- Steering Assist Warning Light: Some Mercedes-Benz models have a specific warning light for steering assist systems, which can be activated by SAS problems.

Malfunctioning Safety Systems

A miscalibrated steering angle sensor can cause various safety systems to malfunction, leading to unpredictable vehicle behavior:

- Erratic ESP Engagement: The ESP system may engage unnecessarily, applying brakes to individual wheels even when there is no loss of traction. This can feel like a sudden, unexpected deceleration.

- Failure of ESP to Engage: Conversely, the ESP system may fail to engage when needed, such as during a skid or loss of control. This can significantly increase the risk of an accident.

- Adaptive Cruise Control Issues: The ACC system may struggle to maintain a consistent speed or distance from other vehicles. It might accelerate or decelerate abruptly or fail to follow the curvature of the road properly.

- Lane Keeping Assist Problems: The LKA system may make incorrect steering corrections, causing the vehicle to drift or wander within its lane. This can be both annoying and potentially dangerous.

Unusual Driving Behavior

In addition to warning lights and system malfunctions, a miscalibrated SAS can also cause noticeable changes in the vehicle’s driving behavior:

- Steering Wheel Off-Center: The steering wheel may not be centered when driving straight. This can be a subtle but persistent indication of SAS misalignment.

- Difficulty Maintaining a Straight Line: The vehicle may tend to pull to one side, requiring constant steering adjustments to keep it on course.

- Uneven Braking: The brakes may feel uneven or grabby, particularly when turning. This can be a result of the ESP system applying brakes independently due to incorrect SAS data.

Expert Insight

According to a technical bulletin from Mercedes-Benz, a miscalibrated SAS can also affect the performance of other systems, such as the tire pressure monitoring system (TPMS) and the automatic headlamp leveling system. The interconnectedness of these systems highlights the importance of maintaining an accurately calibrated SAS.

4. Tools Required for Steering Angle Sensor Calibration

What tools are essential for steering angle sensor calibration on Mercedes-Benz vehicles? Calibrating the steering angle sensor on Mercedes-Benz vehicles requires specialized tools, including diagnostic scanners, alignment equipment, and software, all of which are comprehensively supported by MERCEDES-DIAGNOSTIC-TOOL.EDU.VN to ensure accurate and effective calibration.

Diagnostic Scanners

A diagnostic scanner is the most critical tool for steering angle sensor calibration. These scanners can read and interpret data from the vehicle’s computer systems, allowing technicians to identify and address issues. Key features to look for in a diagnostic scanner include:

- Mercedes-Benz Specific Software: The scanner should be equipped with software that is specifically designed for Mercedes-Benz vehicles. This ensures compatibility and access to the necessary calibration routines.

- Live Data Streaming: The ability to view live data from the SAS and related sensors is crucial for assessing the sensor’s performance and identifying any discrepancies.

- Calibration Function: The scanner must have a built-in function for performing SAS calibration. This typically involves following on-screen prompts and entering specific values.

- Bi-Directional Control: Bi-directional control allows the technician to send commands to the vehicle’s systems, enabling active testing and calibration procedures.

Alignment Equipment

Wheel alignment equipment is also essential, particularly if the SAS calibration is being performed after a wheel alignment adjustment. Accurate alignment ensures that the steering wheel is properly centered, which is a prerequisite for SAS calibration. Key components of alignment equipment include:

- Alignment Rack: A level alignment rack provides a stable platform for performing wheel alignment adjustments.

- Alignment Heads: These devices attach to the wheels and measure the angles of each wheel relative to the vehicle’s centerline.

- Software: Alignment software provides real-time readings and guides the technician through the alignment process.

Other Necessary Tools

In addition to diagnostic scanners and alignment equipment, several other tools can be helpful for SAS calibration:

- Scan Tool Cables and Adapters: Ensure you have the correct cables and adapters to connect the diagnostic scanner to the vehicle’s diagnostic port.

- Battery Support Unit: Maintaining a stable voltage during calibration is essential to prevent errors. A battery support unit provides a constant power supply.

- Torque Wrenches: Using torque wrenches to tighten suspension components to the correct specifications is crucial for maintaining proper alignment.

- Service Information: Access to accurate service information, such as repair manuals and technical bulletins, is essential for following the correct calibration procedures.

Software and Updates

Keeping the diagnostic scanner’s software up-to-date is critical for accessing the latest calibration routines and bug fixes. Many scanner manufacturers offer subscription services that provide regular software updates.

According to a study by the Automotive Service Association (ASA), using updated diagnostic software can reduce diagnostic time by as much as 50%. This highlights the importance of investing in and maintaining modern diagnostic tools.

5. Step-by-Step Guide: Calibrating SAS Using Mercedes Diagnostics

How do you calibrate a steering angle sensor using Mercedes diagnostic tools? Calibrating the steering angle sensor (SAS) on a Mercedes-Benz involves a detailed process using diagnostic tools to ensure accuracy. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide comprehensive, step-by-step guidance on this procedure to guarantee optimal results.

Step 1: Preparation

- Park the Vehicle: Park the Mercedes-Benz on a level surface. Ensure the steering wheel is centered and the wheels are pointing straight ahead.

- Gather Tools: Collect the necessary tools, including a Mercedes-Benz compatible diagnostic scanner, scan tool cables, and a battery support unit.

- Access Service Information: Consult the vehicle’s service manual or a reputable online database for the specific calibration procedure for your Mercedes-Benz model.

- Connect Battery Support Unit: Connect the battery support unit to maintain a stable voltage during the calibration process.

Step 2: Connect Diagnostic Scanner

- Locate Diagnostic Port: Find the diagnostic port (OBD-II port) in your Mercedes-Benz. It is typically located under the dashboard on the driver’s side.

- Connect Scanner: Plug the diagnostic scanner into the OBD-II port.

- Power On: Turn on the diagnostic scanner and allow it to boot up.

Step 3: Access SAS Calibration Function

- Identify Vehicle: Use the scanner to identify your Mercedes-Benz model. This may involve entering the VIN (Vehicle Identification Number) or selecting the model from a list.

- Navigate to SAS Function: Navigate through the scanner’s menu to find the steering angle sensor function. This may be located under “Chassis,” “Stability Control,” or “Calibration.”

- Select Calibration Routine: Choose the appropriate calibration routine for your vehicle. The scanner may offer several options, such as “SAS Calibration,” “Zero Point Calibration,” or “Steering Angle Reset.”

Step 4: Perform Calibration

- Follow On-Screen Prompts: Carefully follow the on-screen prompts provided by the diagnostic scanner. These prompts will guide you through the calibration process.

- Center Steering Wheel: The scanner may instruct you to ensure the steering wheel is centered. Verify that the wheels are pointing straight ahead.

- Enter Values: The scanner may ask you to enter specific values or perform certain actions, such as turning the steering wheel lock-to-lock (from full left to full right).

- Complete Calibration: Once you have followed all the prompts, the scanner will indicate that the calibration is complete.

Step 5: Verify Calibration

- Read SAS Data: Use the scanner to read the steering angle sensor data. Verify that the sensor is reading zero degrees when the steering wheel is centered.

- Road Test: Perform a road test to ensure the ESP, ACC, and LKA systems are functioning correctly. Pay attention to any warning lights or unusual vehicle behavior.

- Recheck Codes: After the road test, recheck the vehicle for any diagnostic trouble codes (DTCs). Clear any codes that may have been generated during the calibration process.

Expert Tips

According to a technical service bulletin from Mercedes-Benz, some models may require additional steps, such as performing a yaw rate sensor calibration or a lateral acceleration sensor calibration. Always consult the vehicle’s service information for specific instructions.

6. Mercedes-Benz Specific Calibration Procedures

Are there unique procedures for calibrating steering angle sensors on different Mercedes-Benz models? Yes, calibration procedures can vary significantly across different Mercedes-Benz models and years. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we provide detailed, model-specific guides to ensure accurate calibration, regardless of the vehicle.

Model-Specific Variations

Mercedes-Benz has implemented various steering angle sensor designs and calibration procedures over the years. These variations can be influenced by factors such as:

- Vehicle Age: Older models may have simpler calibration routines compared to newer vehicles with more advanced systems.

- Chassis Type: Different chassis types (e.g., C-Class, E-Class, S-Class) may have unique SAS configurations and calibration requirements.

- Option Packages: Vehicles equipped with specific option packages, such as adaptive cruise control or lane keeping assist, may require additional calibration steps.

Examples of Model-Specific Procedures

Here are a few examples of how SAS calibration procedures can vary across different Mercedes-Benz models:

- C-Class (W204): On some W204 C-Class models, the SAS calibration may require performing a full lock-to-lock steering maneuver while the vehicle is stationary. The diagnostic scanner will then prompt you to confirm the calibration.

- E-Class (W212): The W212 E-Class may require a more complex calibration routine that involves driving the vehicle at a specific speed for a certain distance. The scanner will monitor the SAS data and automatically calibrate the sensor.

- S-Class (W221): On the W221 S-Class, the SAS calibration may be integrated with the calibration of other sensors, such as the yaw rate sensor and the lateral acceleration sensor. The scanner will guide you through a series of steps to calibrate all the sensors simultaneously.

Importance of Service Information

Due to these model-specific variations, it is crucial to consult the vehicle’s service information before attempting to calibrate the SAS. The service information will provide detailed instructions, including:

- Required Tools: The specific diagnostic scanner and any other necessary tools.

- Calibration Procedure: The exact steps to follow during the calibration process.

- Specifications: The acceptable range for SAS data and other relevant parameters.

- Troubleshooting Tips: Common issues that may arise during calibration and how to resolve them.

Accessing Service Information

Service information for Mercedes-Benz vehicles can be obtained from several sources:

- Mercedes-Benz WIS (Workshop Information System): This is the official Mercedes-Benz service information database, which is available to authorized repair shops and technicians.

- Aftermarket Service Information Providers: Several aftermarket companies, such as Mitchell 1 and Alldata, offer comprehensive service information databases for a wide range of vehicles.

- Online Forums and Communities: Online forums and communities dedicated to Mercedes-Benz vehicles can be a valuable source of information, but it is important to verify the accuracy of any information obtained from these sources.

Expert Advice

According to a Mercedes-Benz technical trainer, failing to follow the correct model-specific calibration procedure can result in inaccurate SAS data and malfunctioning safety systems. Always take the time to consult the service information and follow the instructions carefully.

7. Advanced Diagnostic Procedures for SAS Issues

What advanced diagnostic techniques can help resolve complex SAS issues in Mercedes-Benz vehicles? Addressing complex steering angle sensor (SAS) issues requires advanced diagnostic procedures, including data analysis, sensor testing, and component inspections. At MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, we offer guidance on these advanced techniques.

Analyzing Live Data

One of the most valuable diagnostic techniques for SAS issues is analyzing live data from the sensor and related systems. This involves using a diagnostic scanner to monitor the SAS data in real-time while the vehicle is being driven or manipulated. Key parameters to monitor include:

- Steering Angle: The current angle of the steering wheel, as measured by the SAS.

- Steering Angle Rate: The rate at which the steering wheel is being turned.

- Yaw Rate: The rate at which the vehicle is rotating around its vertical axis.

- Lateral Acceleration: The acceleration of the vehicle in a direction perpendicular to its direction of travel.

By comparing these parameters, a technician can identify discrepancies that may indicate a problem with the SAS or related systems. For example:

- Inconsistent Steering Angle: If the steering angle data is inconsistent or erratic, it may indicate a faulty SAS.

- Yaw Rate Discrepancy: If the yaw rate does not match the steering angle, it may indicate a problem with the yaw rate sensor or the ESP system.

- Lateral Acceleration Anomaly: If the lateral acceleration is not consistent with the steering angle and yaw rate, it may indicate a problem with the lateral acceleration sensor or the ESP system.

Sensor Testing

In addition to analyzing live data, it may also be necessary to perform specific tests on the SAS and related sensors. These tests can help to determine if the sensors are functioning correctly and providing accurate data. Common sensor tests include:

- Resistance Test: Measuring the resistance of the SAS wiring to check for opens or shorts.

- Voltage Test: Measuring the voltage output of the SAS to check for proper signal strength.

- Ground Test: Checking the ground connection of the SAS to ensure it is properly grounded.

Component Inspection

A thorough component inspection can also help to identify SAS issues. This involves visually inspecting the SAS, its wiring, and related components for any signs of damage or corrosion. Key areas to inspect include:

- SAS Housing: Check the SAS housing for cracks or damage.

- Wiring Harness: Inspect the wiring harness for frayed wires, loose connections, or corrosion.

- Connectors: Check the connectors for corrosion or damage.

- Steering Column: Inspect the steering column for any signs of damage or wear.

Expert Insight

According to a Mercedes-Benz diagnostic specialist, SAS issues can sometimes be caused by problems with the vehicle’s electrical system. Always check the battery voltage, charging system, and ground connections before proceeding with more extensive diagnostic procedures.

8. Potential Problems During Calibration and How to Solve Them

What common issues might occur during steering angle sensor calibration and how can they be resolved? During steering angle sensor calibration, you may encounter issues such as communication errors, incorrect readings, or calibration failures. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive troubleshooting guidance.

Communication Errors

One of the most common problems during SAS calibration is a communication error between the diagnostic scanner and the vehicle’s computer system. This can prevent the scanner from accessing the SAS function or completing the calibration process. Common causes of communication errors include:

- Incorrect Scanner: Using a diagnostic scanner that is not compatible with the vehicle.

- Faulty Cables: Damaged or loose scan tool cables.

- Software Issues: Outdated or corrupted scanner software.

- Vehicle Issues: Problems with the vehicle’s diagnostic port or wiring.

Solutions

- Verify Compatibility: Ensure that the diagnostic scanner is compatible with the vehicle’s make, model, and year.

- Check Cables: Inspect the scan tool cables for damage and ensure they are securely connected to the scanner and the vehicle’s diagnostic port.

- Update Software: Update the diagnostic scanner’s software to the latest version.

- Inspect Diagnostic Port: Check the vehicle’s diagnostic port for damage or corrosion.

Incorrect Readings

Another common issue is incorrect SAS readings. This can occur if the SAS is faulty or if there is a problem with the vehicle’s alignment. Common causes of incorrect readings include:

- Faulty SAS: A damaged or malfunctioning SAS.

- Alignment Issues: Misalignment of the wheels or steering wheel.

- Sensor Interference: Interference from other sensors or electrical components.

Solutions

- Replace SAS: If the SAS is faulty, it will need to be replaced.

- Perform Alignment: Ensure that the vehicle’s wheels and steering wheel are properly aligned.

- Check for Interference: Look for any sources of interference that may be affecting the SAS readings.

Calibration Failures

In some cases, the SAS calibration process may fail to complete successfully. This can occur for a variety of reasons, including:

- Low Battery Voltage: Insufficient battery voltage during the calibration process.

- Interrupted Calibration: Interrupting the calibration process before it is complete.

- Software Errors: Bugs or glitches in the diagnostic scanner’s software.

Solutions

- Maintain Voltage: Use a battery support unit to maintain a stable voltage during the calibration process.

- Avoid Interruptions: Ensure that the calibration process is not interrupted before it is complete.

- Restart Scanner: If the calibration fails due to a software error, try restarting the diagnostic scanner and repeating the process.

Expert Advice

According to a Mercedes-Benz master technician, if you encounter persistent problems during SAS calibration, it may be necessary to consult with a qualified technician or refer to the vehicle’s service manual for additional troubleshooting guidance.

9. Best Practices for Maintaining Steering Angle Sensor Accuracy

How can you ensure the long-term accuracy of the steering angle sensor in a Mercedes-Benz? To maintain steering angle sensor accuracy, follow best practices such as regular inspections, proper alignment, and timely recalibration. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers expert advice.

Regular Inspections

One of the most effective ways to maintain SAS accuracy is to perform regular inspections. These inspections should include:

- Visual Inspection: Check the SAS, its wiring, and related components for any signs of damage or corrosion.

- Data Monitoring: Use a diagnostic scanner to monitor the SAS data and look for any inconsistencies or anomalies.

- System Testing: Perform regular tests of the ESP, ACC, and LKA systems to ensure they are functioning correctly.

Proper Alignment

Proper wheel alignment is crucial for maintaining SAS accuracy. Misalignment can cause the steering wheel to be off-center, which can affect the SAS readings and lead to malfunctioning safety systems. Best practices for wheel alignment include:

- Regular Alignment Checks: Have the vehicle’s alignment checked at regular intervals, typically every 6,000 to 12,000 miles.

- Alignment After Repairs: Perform a wheel alignment after any repairs or modifications to the suspension system.

- Use Quality Equipment: Use quality alignment equipment and follow the manufacturer’s instructions carefully.

Timely Recalibration

Recalibrating the SAS whenever necessary is essential for maintaining its accuracy. Common scenarios that may require recalibration include:

- Wheel Alignment: After adjusting the wheel alignment.

- Suspension Work: After any repairs or modifications to the suspension system.

- SAS Replacement: After replacing the SAS.

- Battery Replacement: In some Mercedes-Benz models, after disconnecting and reconnecting the battery.

Expert Insight

According to a study by the AAA Foundation for Traffic Safety, proper vehicle maintenance, including regular alignment checks and timely SAS recalibration, can significantly reduce the risk of accidents.

10. Benefits of Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for SAS Calibration

What benefits do you gain by using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for steering angle sensor calibration? Using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for your SAS calibration provides access to expert guidance, detailed tutorials, and comprehensive support.

Expert Guidance

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides expert guidance on all aspects of SAS calibration, including:

- Tool Selection: Assistance in choosing the right diagnostic scanner and other tools for your Mercedes-Benz model.

- Procedure Assistance: Step-by-step instructions and troubleshooting tips for performing SAS calibration.

- Data Interpretation: Guidance on interpreting SAS data and identifying potential problems.

Detailed Tutorials

The website offers detailed tutorials on SAS calibration, covering a wide range of Mercedes-Benz models. These tutorials include:

- Step-by-Step Instructions: Clear, concise instructions for each step of the calibration process.

- Visual Aids: Photos and videos to illustrate key concepts and procedures.

- Troubleshooting Tips: Common issues and how to resolve them.

Comprehensive Support

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides comprehensive support to help you with your SAS calibration needs, including:

- Online Forum: A forum where you can ask questions and get answers from experts and other users.

- Technical Support: Direct access to technical support from qualified technicians.

- Remote Assistance: Remote diagnostic and calibration services.

Expert Insight

According to customer feedback, using MERCEDES-DIAGNOSTIC-TOOL.EDU.VN has significantly improved the accuracy and efficiency of SAS calibration, resulting in safer and more reliable vehicles.

11. FAQ: Steering Angle Sensor Calibration on Mercedes-Benz Vehicles

What are some frequently asked questions about steering angle sensor calibration on Mercedes-Benz vehicles? Here are some frequently asked questions (FAQs) regarding steering angle sensor calibration on Mercedes-Benz vehicles, addressing common concerns and providing expert answers.

Q1: What is a steering angle sensor (SAS)?

A1: The steering angle sensor (SAS) is a sensor that measures the position of the steering wheel, providing data to the vehicle’s electronic stability program (ESP) and other safety systems.

Q2: Why is SAS calibration necessary?

A2: SAS calibration is necessary to ensure the accuracy of the ESP and other safety systems. Miscalibration can lead to malfunctioning systems and increased risk of accidents.

Q3: When should I calibrate the SAS?

A3: You should calibrate the SAS after wheel alignment, suspension work, SAS replacement, or battery replacement.

Q4: What tools are required for SAS calibration?

A4: You will need a Mercedes-Benz compatible diagnostic scanner, scan tool cables, and a battery support unit.

Q5: How do I access the SAS calibration function on the diagnostic scanner?

A5: Navigate through the scanner’s menu to find the steering angle sensor function. This may be located under “Chassis,” “Stability Control,” or “Calibration.”

Q6: What are the common symptoms of a miscalibrated SAS?

A6: Common symptoms include warning lights on the dashboard, malfunctioning safety systems, and unusual driving behavior.

Q7: Can I calibrate the SAS myself?

A7: Yes, you can calibrate the SAS yourself if you have the necessary tools and knowledge. However, it is important to follow the correct procedures and consult the vehicle’s service information.

Q8: What are the potential problems during calibration?

A8: Potential problems include communication errors, incorrect readings, and calibration failures.

Q9: How can I maintain SAS accuracy?

A9: You can maintain SAS accuracy by performing regular inspections, ensuring proper wheel alignment, and recalibrating the SAS whenever necessary.

Q10: Where can I find expert guidance on SAS calibration?

A10: You can find expert guidance on MERCEDES-DIAGNOSTIC-TOOL.EDU.VN.

12. Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for Expert Assistance

Looking for expert assistance with your Mercedes-Benz steering angle sensor calibration? Contact MERCEDES-DIAGNOSTIC-TOOL.EDU.VN today for personalized support, detailed guidance, and professional services to ensure accurate and reliable results.

If you’re facing challenges with steering angle sensor calibration or need expert advice on maintaining your Mercedes-Benz, don’t hesitate to reach out. Our team at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is ready to provide the support you need.

Contact Information

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

Whether you’re a Mercedes-Benz owner, a professional technician, or an automotive enthusiast, we’re here to help. Contact us today to ensure your Mercedes-Benz performs at its best. Get in touch now for reliable solutions and expert advice.