What Are The Diagnostic Tools Used For End-of-line Testing In Mercedes-Benz Manufacturing? The diagnostic tools used for end-of-line testing in Mercedes-Benz manufacturing are essential for ensuring vehicle quality and performance, and MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive insights into these tools and their applications. By understanding these diagnostic processes, technicians and enthusiasts can effectively maintain and troubleshoot Mercedes-Benz vehicles, maximizing their longevity and reliability. Explore the latest advancements in automotive diagnostics, vehicle configuration, and automotive assembly line testing with us.

Contents

- 1. Understanding End-Of-Line (EOL) Testing in Mercedes-Benz Manufacturing

- 1.1. Key Objectives of EOL Testing

- 1.2. Benefits of Thorough EOL Testing

- 2. Types of Diagnostic Tools Used in Mercedes-Benz EOL Testing

- 2.1. Diagnostic Scanners

- 2.2. Sensor Calibration Tools

- 2.3. Functional Testing Equipment

- 2.4. Specialized Software and Databases

- 3. The EOL Testing Process: A Step-by-Step Overview

- 3.1. Initial Diagnostics

- 3.2. Functional Tests

- 3.3. Sensor Calibration

- 3.4. Final Verification

- 4. Specific Diagnostic Tools Used for Different Mercedes-Benz Systems

- 4.1. Engine Diagnostics

- 4.2. Transmission Diagnostics

- 4.3. ABS and Brake System Diagnostics

- 4.4. ADAS Diagnostics and Calibration

- 5. The Role of Data Analysis in EOL Testing

- 5.1. Identifying Trends

- 5.2. Predicting Potential Issues

- 5.3. Improving Manufacturing Quality

- 6. Advancements in Diagnostic Technology for EOL Testing

- 6.1. AI-Powered Diagnostics

- 6.2. Remote Diagnostics

- 6.3. Enhanced Sensor Technology

- 7. Ensuring Compliance and Standards in Mercedes-Benz EOL Testing

- 7.1. Adherence to Industry Standards

- 7.2. Regular Audits and Assessments

- 7.3. Certified Testing Equipment

- 8. Training and Certification for Technicians in EOL Testing

- 8.1. Specialized Training Programs

- 8.2. Certification Requirements

- 8.3. Continuous Education

- 9. Future Trends in End-Of-Line Testing

- 9.1. Integration of IoT (Internet of Things)

- 9.2. Predictive Maintenance

- 9.3. Augmented Reality (AR) Applications

- 10. Maximizing Efficiency and Accuracy in Mercedes-Benz EOL Testing

- 10.1. Optimizing Testing Procedures

- 10.2. Investing in Advanced Tools

- 10.3. Continuous Training for Technicians

1. Understanding End-Of-Line (EOL) Testing in Mercedes-Benz Manufacturing

What does end-of-line (EOL) testing involve in Mercedes-Benz manufacturing, and why is it crucial? End-of-line (EOL) testing in Mercedes-Benz manufacturing involves a comprehensive series of diagnostic checks performed on vehicles as they come off the assembly line to ensure every system functions correctly and meets Mercedes-Benz’s stringent quality standards. This process is crucial because it serves as the final checkpoint before the vehicle is shipped to dealerships and customers, guaranteeing reliability and performance from the moment of purchase.

EOL testing is designed to catch any manufacturing defects, assembly errors, or component malfunctions that may have occurred during the production process. By identifying and addressing these issues before the vehicle leaves the factory, Mercedes-Benz can prevent costly warranty repairs, maintain its reputation for quality, and ensure customer satisfaction. EOL testing also plays a vital role in verifying that all vehicle systems, including the engine, transmission, brakes, electronics, and safety features, are operating within specified parameters.

The EOL testing process typically involves a combination of automated diagnostic scans, visual inspections, and functional tests. Diagnostic tools are connected to the vehicle’s onboard diagnostic (OBD) system to read fault codes, monitor sensor data, and verify the performance of various components. Visual inspections are conducted to check for any physical damage, misaligned panels, or other cosmetic defects. Functional tests are performed to evaluate the operation of systems such as the air conditioning, infotainment, and driver-assistance features.

1.1. Key Objectives of EOL Testing

What are the primary objectives of end-of-line testing in the automotive industry? The primary objectives include verifying vehicle functionality, identifying defects, ensuring quality control, and adhering to safety standards.

1. Verifying Vehicle Functionality: Ensuring all systems operate as designed.

2. Identifying Defects: Detecting any manufacturing or assembly errors.

3. Ensuring Quality Control: Meeting stringent Mercedes-Benz standards.

4. Adhering to Safety Standards: Confirming all safety features are functional.

1.2. Benefits of Thorough EOL Testing

What are the key benefits of implementing thorough end-of-line testing in Mercedes-Benz manufacturing processes? The key benefits include enhanced vehicle reliability, reduced warranty claims, improved customer satisfaction, and enhanced brand reputation.

- Enhanced Vehicle Reliability: Minimizing potential issues before customer delivery.

- Reduced Warranty Claims: Lowering repair costs through early detection.

- Improved Customer Satisfaction: Ensuring a high-quality vehicle experience from the start.

- Enhanced Brand Reputation: Reinforcing Mercedes-Benz’s commitment to excellence.

2. Types of Diagnostic Tools Used in Mercedes-Benz EOL Testing

What types of diagnostic tools are utilized during the end-of-line testing phase in Mercedes-Benz manufacturing? Various sophisticated tools are used, including diagnostic scanners, sensor calibration tools, and functional testing equipment. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN provides detailed information and support for each type of tool, ensuring technicians have the knowledge and resources needed to perform accurate and effective diagnostics.

2.1. Diagnostic Scanners

What role do diagnostic scanners play in end-of-line testing? Diagnostic scanners play a crucial role in EOL testing by reading fault codes, monitoring sensor data, and verifying component performance. These scanners connect to the vehicle’s OBD system to access a wealth of diagnostic information, allowing technicians to quickly identify any issues that need to be addressed.

Advanced diagnostic scanners, such as the Mercedes-Benz XENTRY Diagnosis system, offer comprehensive diagnostic capabilities, including the ability to perform guided diagnostics, program control units, and access technical service information. These tools are essential for ensuring that all vehicle systems are functioning correctly and meet Mercedes-Benz’s stringent quality standards.

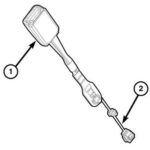

Diagnostic scanners also play a vital role in verifying that all software updates and calibrations have been properly installed. This is particularly important for vehicles with advanced driver-assistance systems (ADAS), which rely on precise sensor data and software algorithms to function correctly. By using diagnostic scanners to confirm that all systems are up-to-date and properly calibrated, Mercedes-Benz can ensure the safety and reliability of its vehicles. The image shows a diagnostic scanner interface that displays real-time data from a vehicle’s systems, highlighting its ability to read and interpret complex diagnostic information.

2.2. Sensor Calibration Tools

How are sensor calibration tools used in Mercedes-Benz end-of-line testing? Sensor calibration tools are used to ensure that sensors, such as those used in ADAS, are accurately calibrated, guaranteeing the systems function as intended. These tools are critical for maintaining the accuracy and reliability of safety and driver-assistance features.

Modern vehicles rely on a variety of sensors to monitor their surroundings and provide input to various control systems. These sensors must be accurately calibrated to ensure that the systems function correctly. For example, radar sensors used in adaptive cruise control systems must be precisely aligned to accurately detect the distance and speed of other vehicles. Similarly, camera sensors used in lane-keeping assist systems must be properly calibrated to accurately identify lane markings.

Sensor calibration tools typically consist of specialized hardware and software that allow technicians to perform precise adjustments to sensor alignment and calibration parameters. These tools often use targets or patterns that are placed in front of the vehicle to provide a reference point for the sensors. By following a specific calibration procedure, technicians can ensure that the sensors are operating within specified tolerances and providing accurate data to the vehicle’s control systems.

2.3. Functional Testing Equipment

What types of functional testing equipment are used in Mercedes-Benz EOL testing? Functional testing equipment includes tools for evaluating engine performance, brake systems, and other critical functions to ensure they meet performance standards. This equipment helps identify any performance issues that may not be detectable through diagnostic scans alone.

Functional testing equipment is used to evaluate the performance of various vehicle systems under real-world conditions. For example, engine dynamometers are used to measure engine power, torque, and emissions output. Brake testing equipment is used to evaluate brake performance, including stopping distance, pedal force, and ABS functionality.

Other types of functional testing equipment include:

- Transmission Testing Equipment: Used to evaluate transmission performance, including shift quality, gear ratios, and torque converter operation.

- Steering System Testing Equipment: Used to evaluate steering system performance, including steering effort, steering angle, and power steering functionality.

- Suspension System Testing Equipment: Used to evaluate suspension system performance, including ride quality, handling, and stability control functionality.

2.4. Specialized Software and Databases

What role do specialized software and databases play in Mercedes-Benz end-of-line testing processes? These resources provide the necessary data, diagnostic procedures, and software updates required for comprehensive vehicle testing. Access to these resources ensures that technicians can accurately diagnose and resolve any issues that arise during EOL testing.

Specialized software and databases are essential for accessing the latest diagnostic information, software updates, and repair procedures. Mercedes-Benz provides its technicians with access to a comprehensive database of technical information, including wiring diagrams, component locations, and diagnostic troubleshooting guides.

This database also includes access to software updates for various vehicle control units. Software updates are often necessary to address known issues, improve performance, or add new features. By ensuring that all vehicle control units are running the latest software, Mercedes-Benz can improve the reliability and functionality of its vehicles.

3. The EOL Testing Process: A Step-by-Step Overview

Can you provide a step-by-step overview of the end-of-line testing process in Mercedes-Benz manufacturing? The EOL testing process involves initial diagnostics, functional tests, sensor calibration, and final verification. This structured approach ensures every aspect of the vehicle is thoroughly evaluated before it leaves the factory.

3.1. Initial Diagnostics

What happens during the initial diagnostics phase of end-of-line testing? During initial diagnostics, a diagnostic scanner is connected to the vehicle’s OBD system to read fault codes and assess the overall health of the vehicle. This step identifies any immediate issues that need attention.

The initial diagnostics phase typically involves the following steps:

- Connecting the Diagnostic Scanner: A technician connects a diagnostic scanner to the vehicle’s OBD port.

- Reading Fault Codes: The scanner reads any stored fault codes from the vehicle’s control units.

- Identifying Issues: Technicians analyze the fault codes to identify any potential problems.

- Documenting Findings: All findings are documented for further investigation and repair.

3.2. Functional Tests

What types of functional tests are performed during EOL testing? Functional tests assess the performance of critical systems such as the engine, transmission, brakes, and electrical components to ensure they meet required standards. These tests verify the vehicle’s operational readiness.

Functional tests may include:

- Engine Performance Test: Evaluating engine power, torque, and emissions.

- Transmission Performance Test: Assessing shift quality and gear ratios.

- Brake System Test: Measuring stopping distance and ABS functionality.

- Electrical System Test: Verifying the operation of lights, sensors, and other electrical components.

3.3. Sensor Calibration

How is sensor calibration performed during end-of-line testing? Sensor calibration involves using specialized tools to ensure sensors, especially those related to ADAS, are accurately calibrated to guarantee the precision and reliability of these systems.

The sensor calibration process typically includes:

- Identifying Sensors: Determining which sensors need calibration.

- Using Calibration Tools: Connecting specialized tools to the vehicle.

- Performing Calibration: Following specific procedures to adjust sensor parameters.

- Verifying Accuracy: Confirming that the sensors are operating within specified tolerances.

3.4. Final Verification

What does the final verification stage of end-of-line testing involve? Final verification includes a comprehensive review of all test results, a visual inspection, and a final diagnostic scan to confirm that all issues have been resolved and the vehicle meets Mercedes-Benz’s quality standards.

The final verification stage usually involves:

- Reviewing Test Results: Analyzing all data collected during the EOL testing process.

- Visual Inspection: Checking for any physical damage or cosmetic defects.

- Final Diagnostic Scan: Performing a final scan to ensure no fault codes are present.

- Documentation: Recording all test results and actions taken.

4. Specific Diagnostic Tools Used for Different Mercedes-Benz Systems

Which specific diagnostic tools are used for testing different systems in Mercedes-Benz vehicles during end-of-line testing? Different tools are used for specific systems, such as the engine, transmission, ABS, and ADAS, each designed to provide detailed diagnostics and ensure optimal performance. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive guides and support for using these tools effectively.

4.1. Engine Diagnostics

What diagnostic tools are specifically used for engine diagnostics during end-of-line testing? Engine diagnostics often involve using tools like the Mercedes-Benz XENTRY system to assess engine performance, identify misfires, and evaluate emissions.

Specific tools and procedures include:

- XENTRY Diagnosis: Mercedes-Benz’s proprietary diagnostic system.

- Engine Analyzers: Tools for measuring engine parameters like compression and oil pressure.

- Emissions Testing Equipment: Devices for evaluating exhaust emissions.

4.2. Transmission Diagnostics

What tools are used for diagnosing transmission issues during Mercedes-Benz end-of-line testing? Transmission diagnostics involve using specialized scanners and software to assess transmission performance, check for fault codes, and evaluate shift quality.

Key tools include:

- XENTRY Diagnosis: For reading transmission-specific fault codes.

- Transmission Analyzers: For assessing hydraulic pressure and shift timing.

- Software Calibration Tools: For updating transmission control unit (TCU) software.

4.3. ABS and Brake System Diagnostics

How are ABS and brake systems tested during the end-of-line process? ABS and brake systems are tested using diagnostic scanners to check sensor functionality, ABS module performance, and overall brake system integrity.

Tools and procedures include:

- ABS Diagnostic Scanners: For reading ABS-specific fault codes.

- Brake Dynamometers: For measuring braking force and stopping distance.

- Hydraulic Pressure Testers: For assessing brake fluid pressure.

4.4. ADAS Diagnostics and Calibration

What diagnostic tools are used for Advanced Driver Assistance Systems (ADAS) during end-of-line testing? ADAS diagnostics require specialized calibration tools and software to ensure sensors like radar and cameras are properly aligned and functioning correctly.

Specific tools include:

- Radar Calibration Tools: For aligning radar sensors used in adaptive cruise control.

- Camera Calibration Tools: For calibrating cameras used in lane-keeping assist systems.

- Software Update Tools: For ensuring ADAS modules have the latest software.

5. The Role of Data Analysis in EOL Testing

How does data analysis contribute to end-of-line testing in Mercedes-Benz manufacturing? Data analysis plays a critical role by identifying trends, predicting potential issues, and improving the overall quality of the manufacturing process. By analyzing data collected during EOL testing, manufacturers can make informed decisions to enhance vehicle reliability and performance.

5.1. Identifying Trends

How does data analysis help in identifying trends during EOL testing? Analyzing EOL testing data helps identify recurring issues or patterns, allowing manufacturers to address systematic problems and improve the consistency of the production process.

By monitoring the frequency and types of faults detected during EOL testing, manufacturers can identify trends that may indicate underlying problems in the manufacturing process. For example, if a particular type of sensor is consistently failing calibration, it may indicate a problem with the sensor manufacturing process or the installation procedure.

5.2. Predicting Potential Issues

How can data analysis be used to predict potential issues in Mercedes-Benz vehicles before they leave the factory? Predictive analysis uses historical data to forecast potential problems, allowing manufacturers to take proactive measures and prevent future defects.

Predictive analysis involves using statistical models and machine learning algorithms to analyze EOL testing data and identify patterns that may indicate a higher risk of future failures. For example, if a vehicle exhibits certain performance characteristics during EOL testing, it may be more likely to experience problems later in its life. By identifying these vehicles before they leave the factory, manufacturers can take corrective action to prevent potential issues.

5.3. Improving Manufacturing Quality

How does data analysis contribute to improving overall manufacturing quality in Mercedes-Benz? Data analysis provides insights into the effectiveness of manufacturing processes, allowing for continuous improvement and optimization to enhance vehicle quality and reliability.

By analyzing EOL testing data, manufacturers can identify areas where the manufacturing process can be improved. For example, if a particular assembly step is consistently resulting in defects, it may indicate a need for better training, improved tooling, or a redesigned process. By implementing these improvements, manufacturers can reduce the number of defects and improve the overall quality of their vehicles.

6. Advancements in Diagnostic Technology for EOL Testing

What are some recent advancements in diagnostic technology used for end-of-line testing in Mercedes-Benz manufacturing? Recent advancements include AI-powered diagnostics, remote diagnostics, and enhanced sensor technology, all aimed at improving the efficiency and accuracy of EOL testing.

6.1. AI-Powered Diagnostics

How is artificial intelligence (AI) being used to improve diagnostic processes in EOL testing? AI-powered diagnostics can analyze complex data patterns, predict potential failures, and provide technicians with actionable insights to resolve issues more efficiently.

AI-powered diagnostic systems use machine learning algorithms to analyze vast amounts of data collected during EOL testing. These systems can identify subtle patterns and anomalies that may be indicative of future problems. For example, an AI-powered system may be able to detect a slight vibration in the engine that is not noticeable to a human technician but could indicate a potential problem with a bearing or other component.

6.2. Remote Diagnostics

What are the benefits of using remote diagnostics in Mercedes-Benz end-of-line testing? Remote diagnostics allow experts to access and analyze vehicle data from a distance, providing real-time support and reducing the need for on-site specialists, thereby streamlining the testing process.

Remote diagnostics involves using telematics and cloud-based technologies to access vehicle data remotely. This allows experts located in a central location to monitor the EOL testing process and provide real-time support to technicians on the factory floor. Remote diagnostics can also be used to perform software updates and calibrations remotely, reducing the need for specialized equipment and personnel on-site.

6.3. Enhanced Sensor Technology

How does enhanced sensor technology improve the accuracy of end-of-line testing? Enhanced sensors provide more precise and comprehensive data, allowing for more accurate diagnostics and ensuring that all vehicle systems meet stringent performance standards.

Enhanced sensor technology involves using advanced sensors that are capable of measuring a wider range of parameters with greater accuracy. For example, advanced vibration sensors can be used to detect subtle vibrations in the engine or transmission that may be indicative of a potential problem. Similarly, advanced pressure sensors can be used to measure hydraulic pressure with greater precision, allowing technicians to identify even minor leaks or malfunctions.

7. Ensuring Compliance and Standards in Mercedes-Benz EOL Testing

How do Mercedes-Benz ensure compliance and adherence to standards during end-of-line testing? Compliance is ensured through rigorous adherence to industry standards, regular audits, and the use of certified testing equipment to guarantee that all vehicles meet regulatory requirements.

7.1. Adherence to Industry Standards

What industry standards are relevant to Mercedes-Benz end-of-line testing? Relevant standards include ISO 9001, IATF 16949, and various regional regulatory requirements to ensure vehicle safety and performance.

Adherence to industry standards is essential for ensuring that the EOL testing process is conducted in a consistent and reliable manner. These standards provide guidelines for the design, implementation, and operation of EOL testing systems. By adhering to these standards, manufacturers can ensure that their vehicles meet the required safety and performance requirements.

7.2. Regular Audits and Assessments

How do regular audits and assessments contribute to maintaining high standards in EOL testing? Regular audits and assessments help identify areas for improvement and ensure that all testing processes are consistently followed, maintaining the integrity of EOL testing.

Regular audits and assessments are conducted to verify that the EOL testing process is being conducted in accordance with established procedures and industry standards. These audits may be conducted by internal quality control teams or by external certification bodies. The results of these audits are used to identify areas where the EOL testing process can be improved.

7.3. Certified Testing Equipment

Why is it important to use certified testing equipment in Mercedes-Benz end-of-line testing? Using certified testing equipment ensures that the tools are accurate, reliable, and compliant with industry standards, providing trustworthy results during the testing process.

Certified testing equipment has been independently tested and verified to meet specific performance standards. This ensures that the equipment is accurate and reliable, and that the results obtained during EOL testing are trustworthy. Using certified testing equipment is essential for ensuring that vehicles meet the required safety and performance requirements.

8. Training and Certification for Technicians in EOL Testing

What kind of training and certification is required for technicians performing end-of-line testing on Mercedes-Benz vehicles? Technicians require specialized training and certification to operate diagnostic tools and interpret test results accurately, ensuring they are competent in performing EOL testing.

8.1. Specialized Training Programs

What do specialized training programs for EOL testing technicians involve? These programs cover the use of diagnostic tools, interpretation of test results, and troubleshooting techniques specific to Mercedes-Benz vehicles, ensuring technicians are well-prepared for their roles.

Specialized training programs provide technicians with the knowledge and skills needed to perform EOL testing effectively. These programs typically cover topics such as:

- Operation of diagnostic tools

- Interpretation of test results

- Troubleshooting techniques

- Vehicle systems knowledge

- Safety procedures

8.2. Certification Requirements

What certifications are typically required for technicians performing end-of-line testing on Mercedes-Benz vehicles? Certifications such as Mercedes-Benz specific certifications or industry-recognized credentials (e.g., ASE) are often required to demonstrate competency in performing EOL testing.

Certification requirements ensure that technicians have the necessary skills and knowledge to perform EOL testing safely and effectively. Certification programs typically involve a combination of classroom training, hands-on experience, and written exams.

8.3. Continuous Education

Why is continuous education important for technicians involved in end-of-line testing? Continuous education is essential to keep technicians updated with the latest diagnostic technologies, testing procedures, and vehicle systems, ensuring they remain competent and effective in their roles.

Continuous education helps technicians stay up-to-date with the latest advancements in diagnostic technology and EOL testing procedures. This is particularly important in the automotive industry, where new technologies and systems are constantly being introduced.

9. Future Trends in End-Of-Line Testing

What are some emerging trends in end-of-line testing that could impact Mercedes-Benz manufacturing? Emerging trends include the integration of IoT (Internet of Things), predictive maintenance, and augmented reality (AR) to enhance EOL testing efficiency and accuracy.

9.1. Integration of IoT (Internet of Things)

How can the integration of IoT enhance end-of-line testing processes? IoT integration allows for real-time data collection and analysis, enabling proactive identification of issues and improving overall testing efficiency.

The integration of IoT involves connecting various devices and sensors used in the EOL testing process to a central network. This allows for real-time data collection and analysis, which can be used to identify potential problems and improve the overall efficiency of the testing process.

9.2. Predictive Maintenance

How will predictive maintenance impact end-of-line testing in the future? Predictive maintenance uses data analytics to forecast potential equipment failures, allowing for timely maintenance and minimizing downtime during EOL testing.

Predictive maintenance involves using data analytics to predict when equipment used in the EOL testing process is likely to fail. This allows for timely maintenance and prevents unexpected downtime, improving the overall efficiency of the testing process.

9.3. Augmented Reality (AR) Applications

In what ways can augmented reality (AR) be used to enhance end-of-line testing procedures? AR can provide technicians with real-time guidance, overlaying digital information onto the physical vehicle to assist with diagnostics and repairs, improving accuracy and efficiency.

Augmented reality (AR) involves using computer-generated images to overlay digital information onto the physical world. In the context of EOL testing, AR can be used to provide technicians with real-time guidance, overlaying digital information onto the vehicle to assist with diagnostics and repairs.

10. Maximizing Efficiency and Accuracy in Mercedes-Benz EOL Testing

What strategies can be employed to maximize efficiency and accuracy in end-of-line testing for Mercedes-Benz vehicles? Strategies include optimizing testing procedures, investing in advanced tools, and providing continuous training to technicians to ensure precise and efficient EOL testing.

10.1. Optimizing Testing Procedures

How can optimizing testing procedures improve the efficiency of end-of-line testing? Streamlining testing processes, reducing redundant steps, and using automated systems can significantly improve testing speed and accuracy.

Optimizing testing procedures involves streamlining the testing process to reduce the amount of time required to complete each test. This can be achieved by eliminating redundant steps, automating repetitive tasks, and using advanced diagnostic tools that provide faster and more accurate results.

10.2. Investing in Advanced Tools

Why is investing in advanced diagnostic tools important for end-of-line testing? Advanced tools provide more accurate and comprehensive data, enabling technicians to identify and resolve issues more efficiently, thereby improving the overall quality of EOL testing.

Investing in advanced diagnostic tools is essential for ensuring that the EOL testing process is conducted accurately and efficiently. Advanced tools provide more comprehensive data, allowing technicians to identify potential problems more quickly and easily.

10.3. Continuous Training for Technicians

How does continuous training contribute to improving the quality of end-of-line testing? Continuous training ensures that technicians are up-to-date with the latest technologies and procedures, enabling them to perform EOL testing with greater accuracy and efficiency.

Continuous training is essential for ensuring that technicians have the knowledge and skills needed to perform EOL testing effectively. Continuous training programs should cover topics such as:

- Operation of diagnostic tools

- Interpretation of test results

- Troubleshooting techniques

- Vehicle systems knowledge

- Safety procedures

By following these strategies, Mercedes-Benz can maximize efficiency and accuracy in its EOL testing processes, ensuring that its vehicles meet the highest standards of quality and reliability.

Do you need expert guidance on diagnostic tools, unlocking hidden features, or repair and maintenance for your Mercedes-Benz? Contact us today at MERCEDES-DIAGNOSTIC-TOOL.EDU.VN, located at 789 Oak Avenue, Miami, FL 33101, United States. Reach us via Whatsapp at +1 (641) 206-8880 for immediate assistance and discover how our services can enhance your Mercedes-Benz experience.