Finding comprehensive training resources for Mercedes diagnostic tools and procedures is crucial for both DIY enthusiasts and professional technicians; MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers a wealth of information and support to help you master Mercedes diagnostics. By using the right resources, you can ensure accurate diagnostics, efficient repairs, and optimal vehicle performance. Explore detailed guides, expert tips, and hands-on training to enhance your proficiency in Mercedes-Benz vehicle diagnostics and repair.

1. What Makes Mercedes Diagnostic Tools and Procedures Unique?

Mercedes-Benz diagnostic tools and procedures stand out due to the sophisticated engineering and advanced technology integrated into these vehicles. This necessitates specialized equipment and in-depth knowledge to accurately diagnose and address issues. Here’s what makes them unique:

- Advanced Technology: Mercedes-Benz vehicles are equipped with complex electronic systems, including numerous sensors, control units, and communication networks.

- Specific Diagnostic Tools: Factory-approved diagnostic tools like the Mercedes-Benz Star Diagnostic System (SDS) are essential for comprehensive diagnostics.

- Software Requirements: Subscription-based software such as Xentry Diagnostics is necessary to access the latest updates, coding, and programming functions.

- Integration with Vehicle Systems: Diagnostic processes are deeply integrated with the vehicle’s systems, requiring a thorough understanding of how each component interacts.

- SCN Coding: Secure Corporate Number (SCN) coding is a Mercedes-Benz requirement whenever electronic control units (ECUs) are serviced. This ensures that the software and hardware are correctly registered with the vehicle’s configuration, maintaining the vehicle’s integrity and performance.

- Vehicle Identification Number (VIN) Lock: Many ECUs within the Supplemental Restraint System (SRS) are VIN-locked, meaning they are specifically coded to a particular vehicle. Proper diagnostic tools are needed to manage and configure these systems effectively.

2. What Key Components Make Up the Mercedes Diagnostic System?

The Mercedes diagnostic system includes several key components that work together to provide comprehensive diagnostic capabilities. Understanding these components is essential for effective vehicle maintenance and repair.

- Mercedes-Benz Star Diagnostic System (SDS): The primary tool for diagnosing Mercedes-Benz vehicles, offering in-depth access to vehicle systems.

- Xentry Diagnostics: Subscription-based software that provides access to diagnostic data, repair information, and programming functions.

- Diagnostic Multiplexer: Hardware interface that connects the diagnostic software to the vehicle’s electronic systems.

- Diagnostic Cables and Connectors: Various cables and connectors are used to establish a reliable connection between the diagnostic tool and the vehicle.

- Software Updates: Regular updates ensure the diagnostic system remains compatible with the latest vehicle models and software versions.

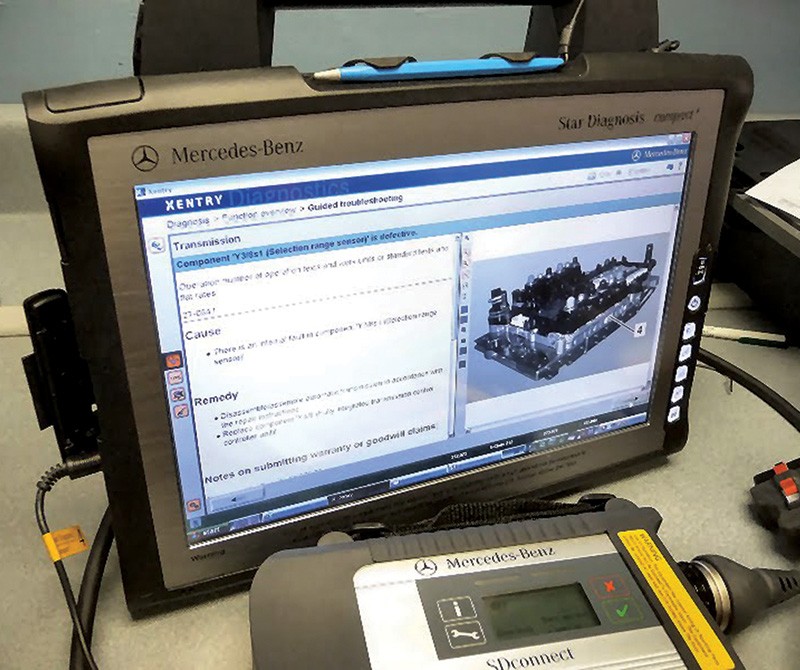

Mercedes-Benz STAR Diagnostic System (SDS) Compact4 scan tool

Mercedes-Benz STAR Diagnostic System (SDS) Compact4 scan tool

3. What Are the Benefits of Using Factory-Approved Diagnostic Tools?

Using factory-approved diagnostic tools offers several advantages over aftermarket alternatives, ensuring more accurate and reliable diagnostics.

- Comprehensive Functionality: Factory tools provide complete access to all vehicle systems and functions, enabling thorough diagnostics.

- Accurate Diagnostics: Designed specifically for Mercedes-Benz vehicles, these tools offer precise diagnostic information and error codes.

- Software Compatibility: Factory tools are always compatible with the latest vehicle software, ensuring accurate readings and reliable performance.

- Access to Updates: Users receive regular software and data updates, keeping the diagnostic system current with the latest vehicle models and technologies.

- Official Support: Access to official support and resources from Mercedes-Benz, providing expert assistance when needed.

- SCN Coding: The ability to perform Secure Corporate Number (SCN) coding ensures that any software updates or module replacements are correctly registered with Mercedes-Benz, maintaining the vehicle’s integrity and warranty.

- VIN-Locked ECUs: Factory tools can handle VIN-locked ECUs, which are common in safety systems like the Supplemental Restraint System (SRS).

4. What Essential Training Resources Are Available for Mercedes Diagnostics?

A variety of training resources are available to help technicians and DIY enthusiasts master Mercedes diagnostics. These resources range from online platforms to hands-on training programs.

- MERCEDES-DIAGNOSTIC-TOOL.EDU.VN: Offers comprehensive guides, expert tips, and hands-on training for Mercedes diagnostics.

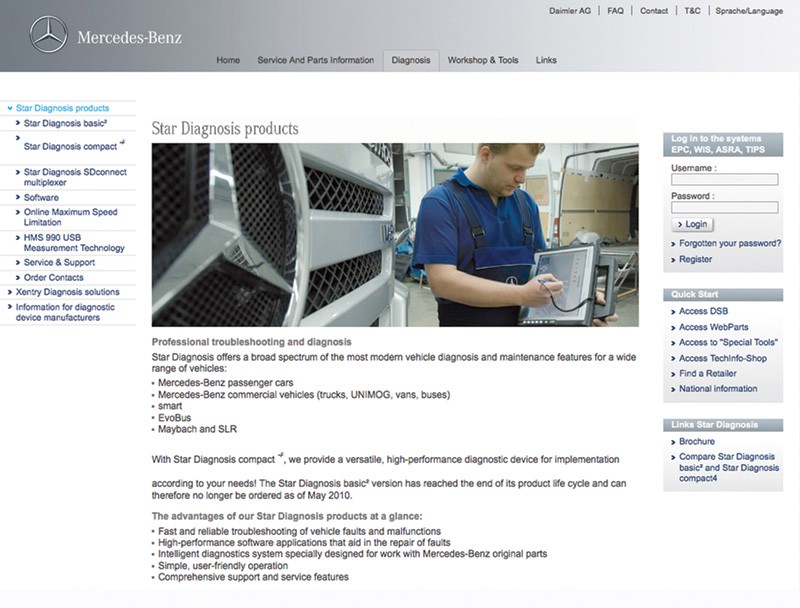

- Star TekInfo: The official Mercedes-Benz USA LLC site, providing technical documentation, service bulletins, and training materials. Visit www.startekinfo.com for more information.

- Mercedes-Benz Technical Training Website: Offers free model-specific PDFs and access to model-specific CDs with detailed information. Visit www.mercedestechstore.com for more information.

- Online Courses: Platforms like Coursera, Udemy, and Skillshare offer courses on automotive diagnostics, including specific modules on Mercedes-Benz vehicles.

- YouTube Tutorials: Numerous channels provide step-by-step tutorials on using diagnostic tools and performing specific procedures on Mercedes-Benz vehicles.

- Industry Forums: Online forums and communities where technicians share knowledge, ask questions, and discuss diagnostic challenges.

technical-training-print-multimedia-training

technical-training-print-multimedia-training

5. What Topics Are Covered in Mercedes Diagnostic Training Programs?

Mercedes diagnostic training programs cover a wide range of topics to ensure participants develop a comprehensive understanding of vehicle systems and diagnostic procedures.

- Vehicle Systems Overview: Understanding the various systems in Mercedes-Benz vehicles, including engine, transmission, brakes, and electrical systems.

- Diagnostic Tool Operation: Learning how to use the Mercedes-Benz Star Diagnostic System (SDS) and other diagnostic tools effectively.

- Software Navigation: Navigating diagnostic software such as Xentry Diagnostics to access vehicle data and perform tests.

- Error Code Interpretation: Understanding and interpreting diagnostic trouble codes (DTCs) to identify potential issues.

- Component Testing: Performing tests on individual components to verify their functionality and identify faults.

- Programming and Coding: Learning how to program and code electronic control units (ECUs) to ensure proper operation.

- Safety Procedures: Adhering to safety procedures when working with high-voltage electrical systems and other potentially hazardous components.

6. What Are the Most Common Diagnostic Procedures for Mercedes Vehicles?

Several diagnostic procedures are commonly performed on Mercedes-Benz vehicles to identify and resolve issues.

- Quick Test: Performing a quick test using the diagnostic tool to scan all vehicle systems for error codes.

- Fault Code Analysis: Analyzing fault codes to identify potential issues and prioritize diagnostic efforts.

- Live Data Monitoring: Monitoring live data from sensors and components to assess their performance in real-time.

- Actuator Testing: Activating actuators to verify their functionality and identify any mechanical or electrical faults.

- Component Testing: Testing individual components using multimeters, oscilloscopes, and other diagnostic tools to pinpoint specific issues.

- Software Updates: Updating vehicle software to address known issues and improve performance.

- SCN Coding: Performing SCN coding after replacing or reprogramming ECUs to ensure compatibility with the vehicle’s system.

- Adaptations and Calibrations: Performing necessary adaptations and calibrations after replacing components, such as calibrating ride height sensors.

7. How Do You Interpret Diagnostic Trouble Codes (DTCs) in Mercedes Vehicles?

Interpreting diagnostic trouble codes (DTCs) is a crucial step in diagnosing Mercedes-Benz vehicles. DTCs provide valuable information about potential issues, helping technicians pinpoint the source of the problem.

- Using Diagnostic Tools: Connect the Mercedes-Benz Star Diagnostic System (SDS) or another compatible diagnostic tool to the vehicle.

- Running a Scan: Perform a comprehensive scan of the vehicle’s systems to retrieve any stored DTCs.

- Identifying the Code: Note the specific DTC code, which usually consists of a letter followed by four or five numbers (e.g., P0101).

- Consulting Resources: Use diagnostic software or online resources to look up the meaning of the DTC.

- Understanding the Description: Read the description of the DTC to understand the potential issue.

- Checking Related Systems: Investigate any related systems or components that may be affected by the DTC.

- Verifying the Issue: Perform additional tests and inspections to verify the issue and confirm the diagnosis.

- Clearing the Code: After addressing the issue, clear the DTC and perform a test drive to ensure the problem is resolved.

8. What Tools Are Needed for Advanced Mercedes Diagnostics?

Advanced Mercedes diagnostics require specialized tools to accurately diagnose and repair complex issues.

- Mercedes-Benz Star Diagnostic System (SDS): The primary tool for comprehensive diagnostics, offering access to all vehicle systems.

- Xentry Diagnostics: Subscription-based software providing access to diagnostic data, repair information, and programming functions.

- Multimeter: Used for testing electrical circuits and components.

- Oscilloscope: Used for analyzing electrical signals and waveforms.

- Scan Tool with Live Data: A scan tool that can display live data from sensors and components in real-time.

- Compression Tester: Used for testing engine compression.

- Fuel Pressure Tester: Used for measuring fuel pressure in the fuel system.

- Smoke Machine: Used for detecting vacuum leaks in the engine.

- Romess Inclinometer: Required for wheel alignments, especially on models with Airmatic and Active Body Control (ABC) systems, to gauge and calibrate ride height.

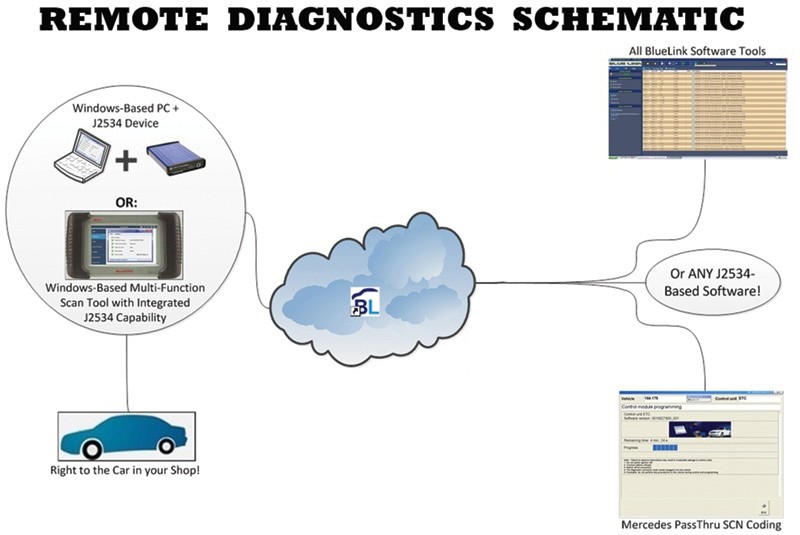

Remote diagnostics schematic

Remote diagnostics schematic

9. How Important Is Software Calibration and Programming in Mercedes Diagnostics?

Software calibration and programming are critical components of Mercedes diagnostics, ensuring that electronic control units (ECUs) function correctly after repairs or replacements.

- ECU Replacement: When replacing an ECU, it must be programmed with the correct software to match the vehicle’s specifications.

- Software Updates: Updating vehicle software can address known issues, improve performance, and enhance security.

- Coding and Configuration: Coding and configuration are necessary to ensure that the ECU is properly integrated with the vehicle’s systems.

- SCN Coding: Mercedes-Benz requires SCN coding whenever ECUs are serviced to verify and update the calibration and programming.

- Adaptations and Calibrations: After replacing components, adaptations and calibrations are necessary to ensure proper operation.

- Safety Systems: Proper programming is essential for safety systems like airbags and seat belt tensioners to function correctly.

- Performance Optimization: Calibrating software can optimize engine performance, fuel efficiency, and emissions.

10. What Are Common Mistakes to Avoid During Mercedes Diagnostics?

Avoiding common mistakes during Mercedes diagnostics can save time, prevent misdiagnoses, and ensure accurate repairs.

- Ignoring Basic Checks: Always start with basic checks, such as inspecting fuses, wiring, and connectors.

- Skipping Fault Code Analysis: Always analyze fault codes to understand the potential issues before proceeding with further diagnostics.

- Relying Solely on Fault Codes: Do not rely solely on fault codes; perform additional tests and inspections to verify the issue.

- Failing to Update Software: Ensure the diagnostic tool and vehicle software are up to date to avoid compatibility issues.

- Incorrect Programming: Ensure ECUs are programmed with the correct software and coding to match the vehicle’s specifications.

- Neglecting Safety Procedures: Always follow safety procedures when working with high-voltage electrical systems and other hazardous components.

- Ignoring Vehicle History: Consider the vehicle’s history of maintenance and repairs when diagnosing issues.

- Using Incompatible Tools: Always use factory-approved or compatible diagnostic tools to ensure accurate readings and reliable performance.

11. What Are the Best Practices for Maintaining Mercedes Diagnostic Tools?

Proper maintenance of Mercedes diagnostic tools is essential to ensure their accuracy, reliability, and longevity.

- Regular Software Updates: Keep the diagnostic software updated with the latest versions to ensure compatibility with new vehicle models and features.

- Proper Storage: Store diagnostic tools in a clean, dry, and secure location to prevent damage and corrosion.

- Cable and Connector Care: Inspect cables and connectors regularly for damage and replace them as needed.

- Battery Maintenance: Keep diagnostic tool batteries charged and replace them when they no longer hold a charge.

- Calibration: Calibrate diagnostic tools regularly to ensure accurate readings and measurements.

- Cleaning: Clean diagnostic tools regularly with a soft, dry cloth to remove dirt and debris.

- Protection from Extreme Temperatures: Avoid exposing diagnostic tools to extreme temperatures, which can damage electronic components.

- Professional Servicing: Have diagnostic tools professionally serviced and inspected periodically to ensure they are functioning correctly.

Mercedes-Benz Portal

Mercedes-Benz Portal

12. How Does Remote Diagnostics Work for Mercedes-Benz Vehicles?

Remote diagnostics offers a convenient and cost-effective alternative to traditional diagnostic methods, allowing technicians to diagnose and repair vehicles from a remote location.

- J-2534 Interface: Remote diagnostics leverages J-2534 interface devices, which Mercedes-Benz supports, to connect vehicles to diagnostic tools and software at a remote location.

- Onsite Diagnosis: Vehicles can be diagnosed and repaired immediately onsite, reducing downtime and improving efficiency.

- Expert Technicians: Remote diagnostics utilizes the expertise of highly specialized technicians who have a thorough understanding of Mercedes-Benz service diagnostics.

- Access to Genuine Information: Affordable access to genuine Mercedes-Benz service information and other resources.

- Cost Savings: Reduces the capital costs associated with tooling up to factory-level capability.

- BlueLink Diagnostic Solutions Inc.: Companies like BlueLink Diagnostic Solutions Inc. offer remote diagnostic services in conjunction with IBM. More information can be found at www.bluelinkdiag.com.

13. What Are the Benefits of Remote Diagnostic Services?

Remote diagnostic services offer several benefits for both technicians and vehicle owners.

- Convenience: Remote diagnostics can be performed from any location, eliminating the need to transport the vehicle to a repair shop.

- Cost Savings: Reduces the cost of diagnostic equipment, software, and training.

- Expert Assistance: Access to expert technicians with specialized knowledge of Mercedes-Benz vehicles.

- Faster Turnaround: Reduces downtime by enabling quick and accurate diagnoses.

- Access to Latest Technology: Access to the latest diagnostic tools and software without the need for constant upgrades.

- Support for Complex Issues: Assistance with diagnosing and resolving complex issues that may be beyond the capabilities of local technicians.

- Improved Customer Satisfaction: Provides customers with faster, more convenient, and more reliable diagnostic services.

14. How Can I Stay Updated on the Latest Mercedes Diagnostic Technologies?

Staying updated on the latest Mercedes diagnostic technologies is essential for providing accurate and effective diagnostic services.

- Attend Training Courses: Participate in training courses offered by Mercedes-Benz and other industry organizations.

- Read Industry Publications: Stay informed by reading industry publications and journals that cover the latest diagnostic technologies.

- Join Online Forums: Participate in online forums and communities to share knowledge and learn from other technicians.

- Follow Industry Experts: Follow industry experts on social media and other platforms to stay updated on the latest trends and developments.

- Attend Trade Shows: Attend trade shows and conferences to see the latest diagnostic tools and technologies in action.

- Subscribe to Newsletters: Subscribe to newsletters from Mercedes-Benz and other industry organizations to receive updates and announcements.

- Visit MERCEDES-DIAGNOSTIC-TOOL.EDU.VN: Regularly visit MERCEDES-DIAGNOSTIC-TOOL.EDU.VN for the latest guides, tips, and training resources.

- Star TekInfo: Regularly check the official Mercedes-Benz USA LLC site for service and repair technical documentation, bulletins, and training resources. Visit www.startekinfo.com for more information.

15. What Is the Role of the Equipment and Tool Institute (ETI) in Mercedes Diagnostics?

The Equipment and Tool Institute (ETI) plays a crucial role in Mercedes diagnostics by facilitating communication between automakers and aftermarket tool manufacturers.

- Data Acquisition: ETI communicates with Mercedes-Benz and other automakers to acquire and archive scan tool data, including algorithms, protocol documents, and diagnostic trouble codes.

- Licensing: Aftermarket tool manufacturers pay licensing fees to ETI to use selected data to develop and build electronic test equipment and other tools.

- Data Gaps: When gaps in scan tool information are identified, ETI works with Mercedes-Benz to gather the data and pass it on to aftermarket manufacturers.

- Collaboration: ETI promotes collaboration between OEMs and the aftermarket to improve vehicle serviceability and ensure that technicians have access to the tools they need.

- Resource: ETI serves as a valuable resource for technicians and shop owners by providing access to information and resources related to diagnostic tools and equipment.

- Industry Standards: ETI helps to establish industry standards for diagnostic tools and equipment, ensuring that they are accurate, reliable, and compatible with Mercedes-Benz vehicles.

Mastering Mercedes diagnostic tools and procedures requires continuous learning, access to reliable resources, and hands-on experience. MERCEDES-DIAGNOSTIC-TOOL.EDU.VN is dedicated to providing you with the knowledge and support you need to excel in Mercedes diagnostics.

For personalized assistance and expert guidance, contact us today:

- Address: 789 Oak Avenue, Miami, FL 33101, United States

- WhatsApp: +1 (641) 206-8880

- Website: MERCEDES-DIAGNOSTIC-TOOL.EDU.VN

FAQ: Mercedes Diagnostic Tools and Procedures

1. What is the best diagnostic tool for Mercedes-Benz vehicles?

The Mercedes-Benz Star Diagnostic System (SDS) is considered the best tool for comprehensive diagnostics, offering complete access to all vehicle systems and functions.

2. How do I interpret diagnostic trouble codes (DTCs) on my Mercedes?

Use a diagnostic tool to retrieve DTCs, then consult diagnostic software or online resources to understand the meaning of each code.

3. How often should I perform a diagnostic scan on my Mercedes-Benz vehicle?

Perform a diagnostic scan whenever you notice unusual symptoms or warning lights, and as part of routine maintenance.

4. Can I use aftermarket diagnostic tools on my Mercedes?

While aftermarket tools can be used, factory-approved tools like the SDS offer more comprehensive functionality and accurate diagnostics.

5. How important is software calibration and programming in Mercedes diagnostics?

Software calibration and programming are crucial for ensuring that electronic control units (ECUs) function correctly after repairs or replacements.

6. What are common mistakes to avoid during Mercedes diagnostics?

Avoid ignoring basic checks, relying solely on fault codes, and failing to update software.

7. How can I stay updated on the latest Mercedes diagnostic technologies?

Attend training courses, read industry publications, and participate in online forums to stay informed.

8. What is the role of SCN coding in Mercedes diagnostics?

SCN coding is required whenever ECUs are serviced to verify and update the calibration and programming, ensuring compatibility with the vehicle’s system.

9. What are the benefits of remote diagnostic services for Mercedes-Benz vehicles?

Remote diagnostic services offer convenience, cost savings, expert assistance, and faster turnaround times.

10. Where can I find reliable training resources for Mercedes diagnostic tools and procedures?

MERCEDES-DIAGNOSTIC-TOOL.EDU.VN offers comprehensive guides, expert tips, and hands-on training for Mercedes diagnostics. Also, check Star TekInfo and Mercedes-Benz Technical Training Website for official resources.